Geared driving gear of power branch having rotation input changing into prodeterming rotation output

A gear mechanism and power distribution technology, which is applied in the transmission of mechanical power, engines, engine functions, etc., can solve the problems of large assembly size, uneven load distribution, and expensive lifting equipment required for disassembly, and achieve the best manufacturing cost , the effect of optimal replacement parts cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

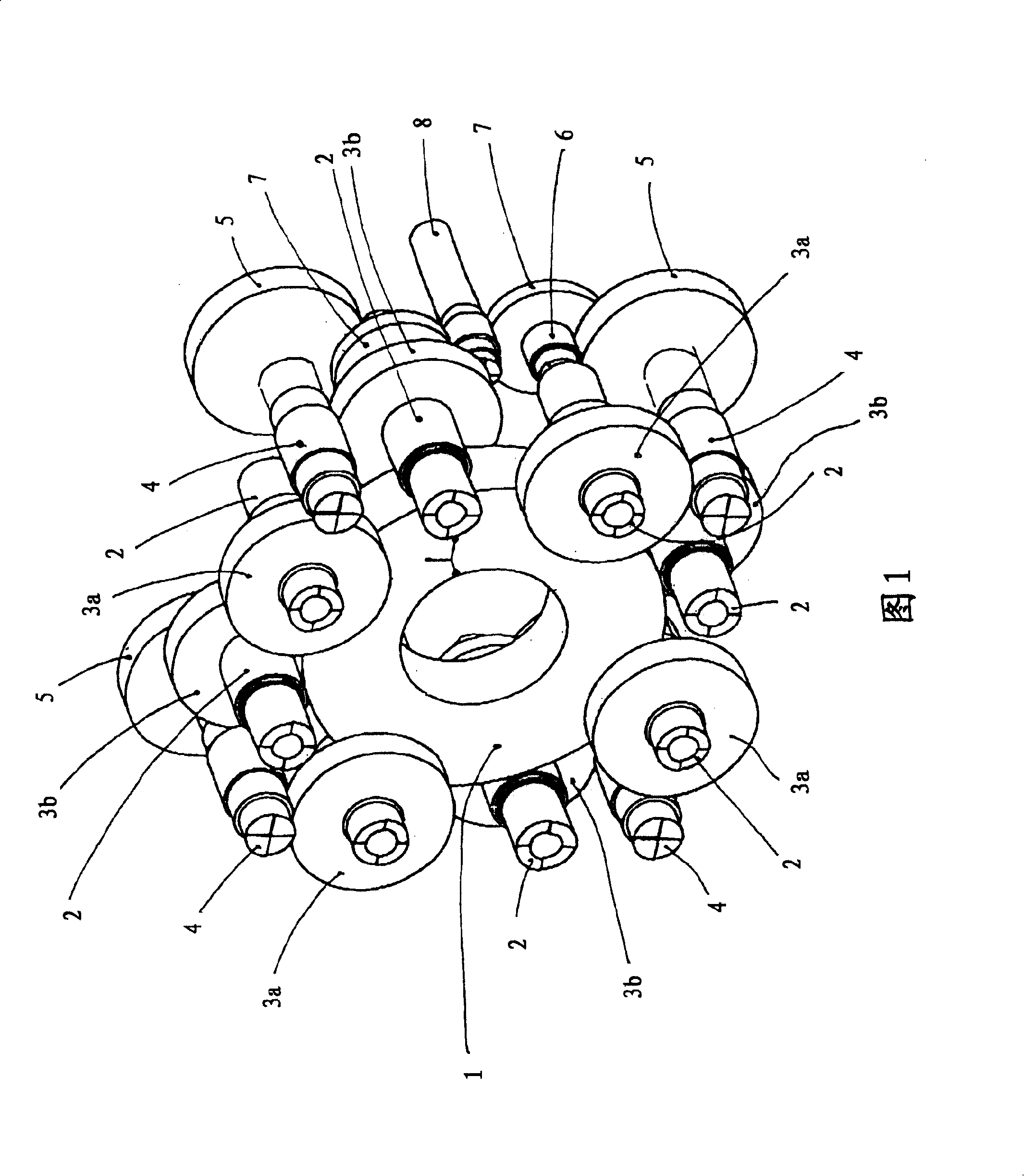

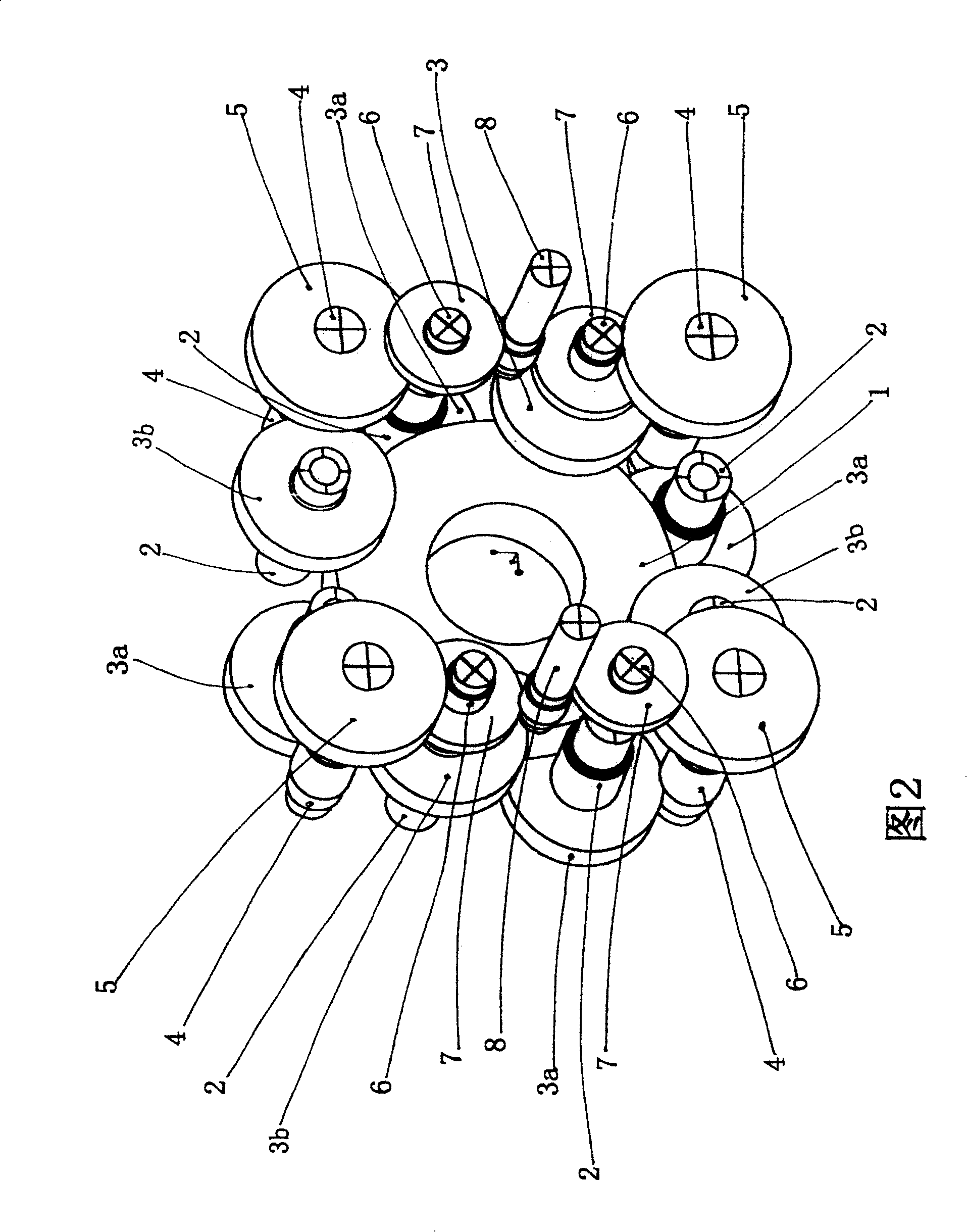

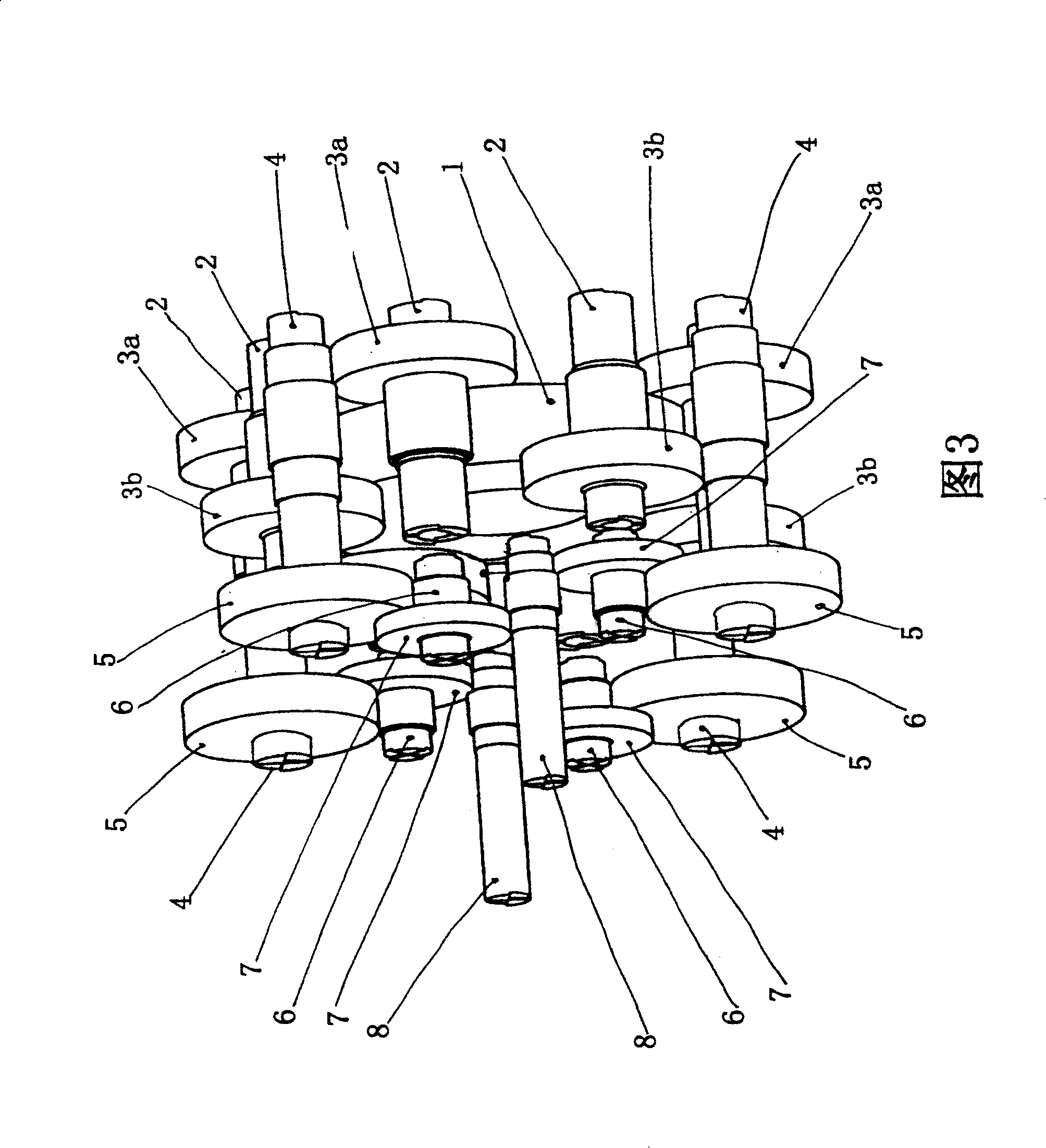

[0029] One embodiment of the gear drive shown in Figures 1-6 is configured as an additional gear drive that augments or augments the rotational output of the rotary power plant by, for example, rotationally driving two generators, said The two generators are driven by the rotor of the rotary power unit, and the gear drive shown in Figure 1-6 is arranged on the table of the rotary power unit between the rotor and the generator. The gear drive comprises a bull gear 1 having gear teeth along its outer circumference. The bull gear 1 is fixedly mounted on a hollow shaft which is supported on bearings at two places inside the gearbox which encloses the gear drive, and the bull gear 1 is coupled to a rotating input shaft which is the rotating power unit. on the rotor shaft.

[0030] Eight pinion shafts 2 are arranged symmetrically around the bull gear 1 , and the pinion gears of the pinion shafts 2 mesh with the bull gear 1 . The bearings of the pinion shaft 2 are arranged in two o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com