Electrically-controlled variable-focus liquid lens based on electrowetting-on-dielectric

An electronically controlled zoom and fluid lens technology, applied in the lens, optics, instruments, etc., can solve the problems of not having the optical axis self-centering characteristic, the influence of gravity, affecting the position of the optical axis, etc., to achieve low power consumption, low cost, imaging clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

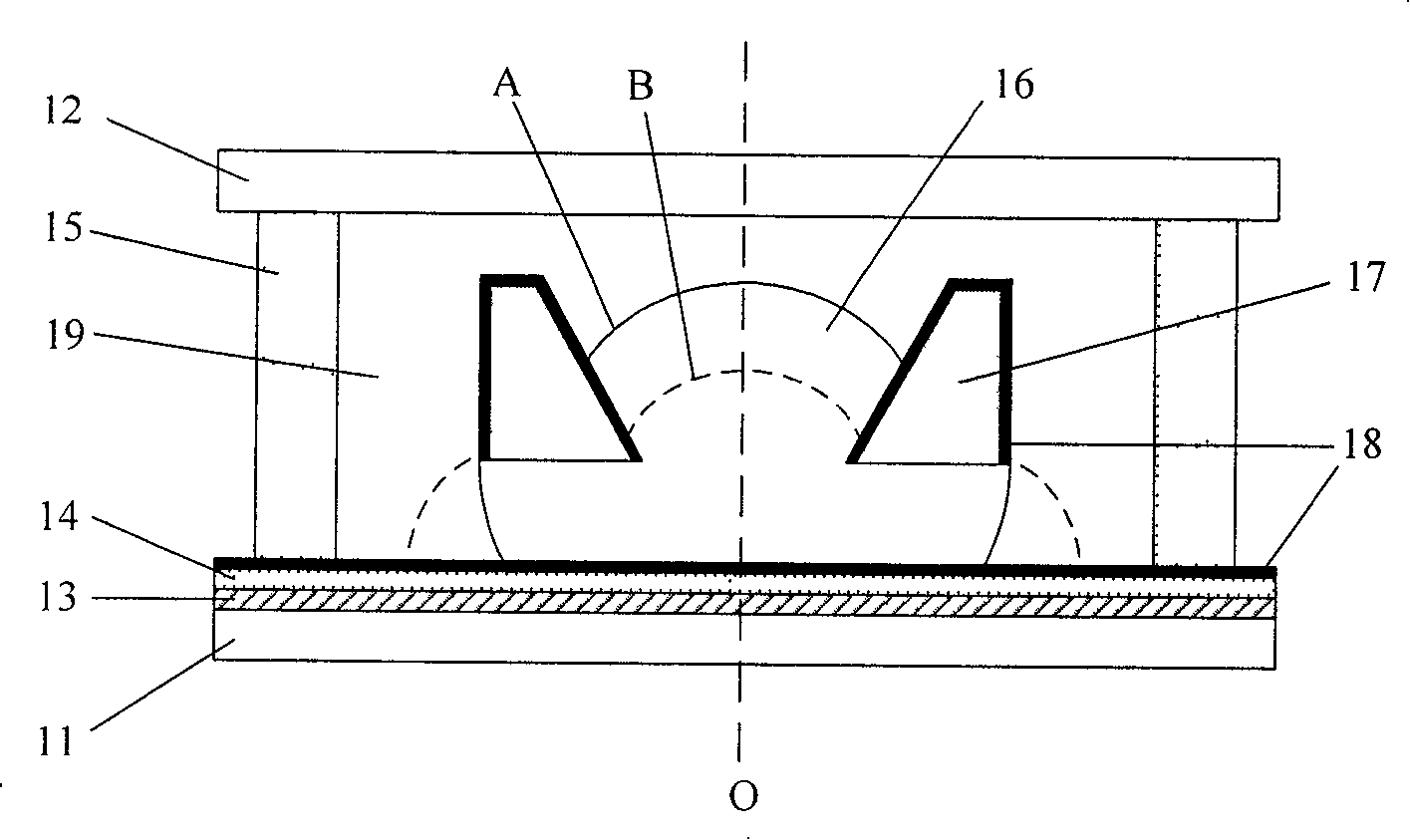

example 1

[0041] like figure 1 shown. On a transparent substrate 11, a transparent conductive film 13 and an insulating dielectric film 14 are covered sequentially. Since the selected insulating dielectric film has a certain degree of hydrophilicity, a strong hydrophobic film 18 is also covered thereon. The hollow chamber 15 is filled with an insulating liquid 19 and a conductive or polar liquid 16 . Both liquids are transparent and immiscible, have different indices of refraction and sufficiently similar densities. In order to make the conductive liquid or polarity 16 at the center position, a conductive ring 17 with a through hole is inserted, the bottom surface of the ring 17 is parallel to the substrate 11 and there is a certain gap between them, the conductive or polar liquid 16 is in this gap and in the through hole of circular ring 17. The generatrix of the through hole of the ring 17 can be a straight line with any inclination angle or an arc curve as required. The bottom su...

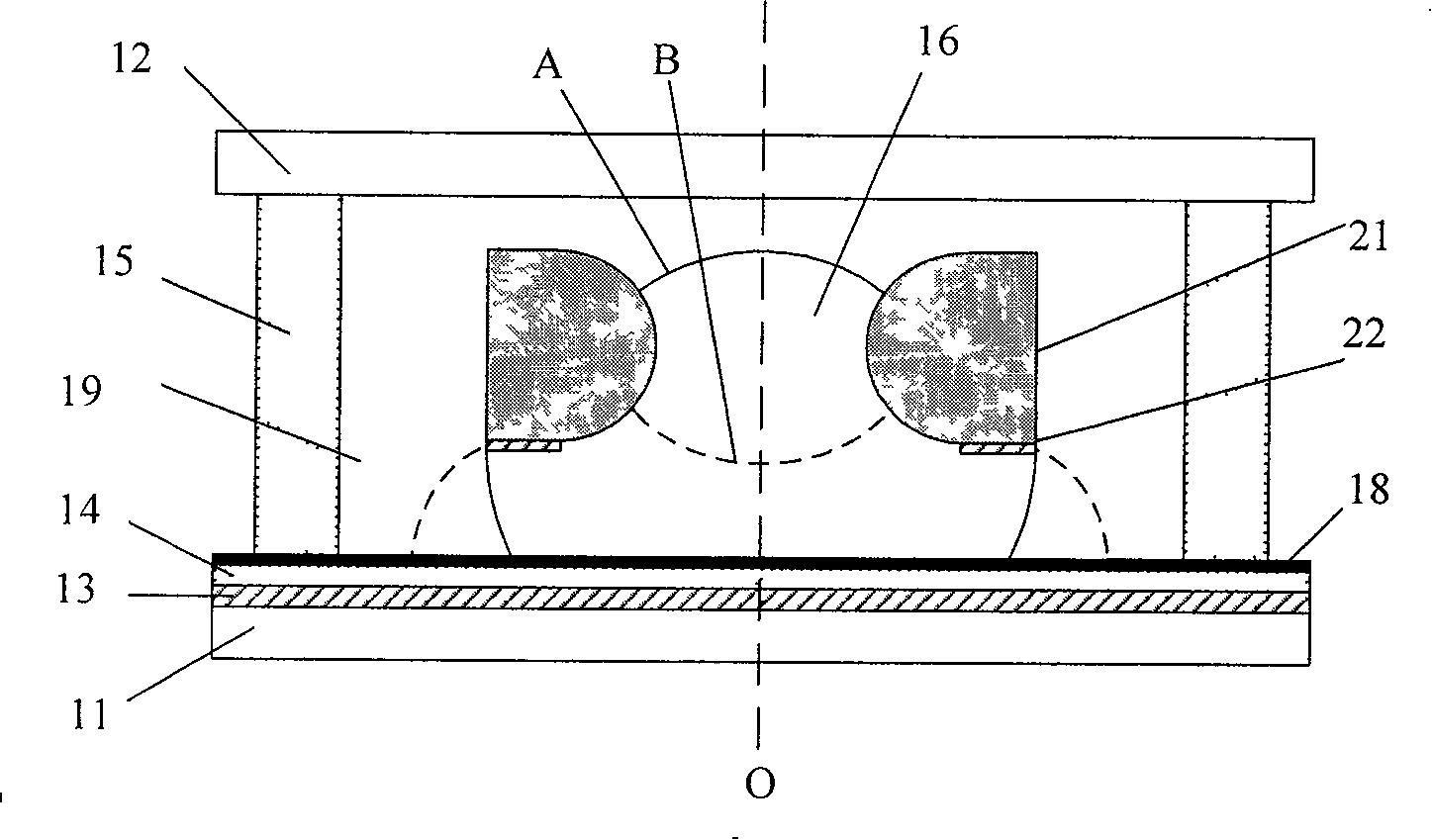

example 2

[0045] figure 2 As shown, the transparent substrate 11, the transparent cover plate 12, the transparent conductive film 13, the insulating dielectric film 14, the hydrophobic film 18, the chamber 15, the conductive or polar liquid 16, the insulating liquid 19 and the central axis O etc. figure 1 Same as described in Example 1 shown. The states described by A and B also represent the position of the conductive liquid when no power is applied and a certain voltage is applied, respectively.

[0046] In this example, the insulating ring 21 for stabilizing the conductive or polar liquid 16 also has a through hole with the O axis. Insulation ring 21 can itself have hydrophobicity, also can become hydrophobicity by the method for surface treatment, and its bottom surface is covered with hydrophilic conductive layer 22, to provide an electrical connection with conductivity or polar liquid 16. touch. figure 2 The through-hole generatrix of the circular ring 21 shown is arc-shaped....

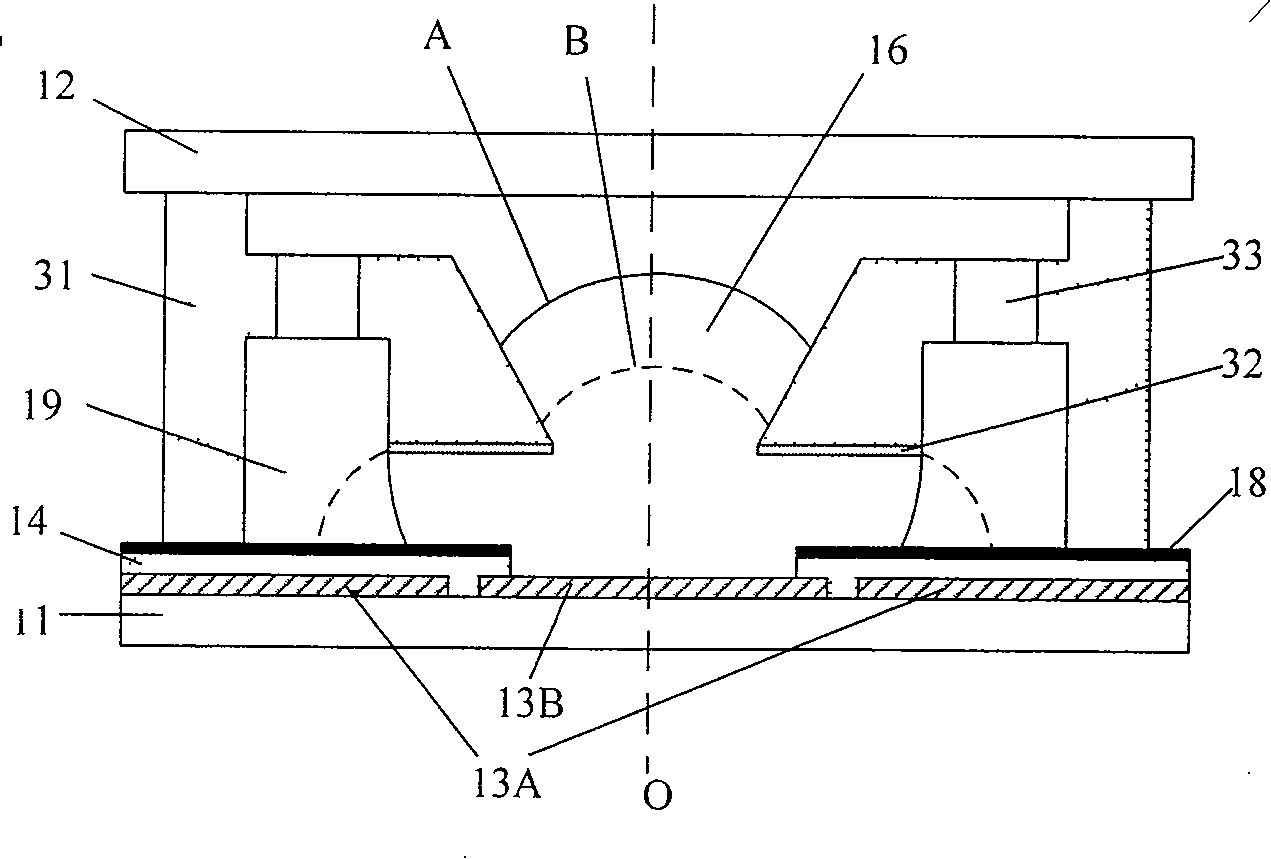

example 3

[0048] image 3 As shown, the transparent substrate 11, the transparent cover plate 12, the insulating dielectric film 14, the hydrophobic film 18, the conductive or polar liquid 16, the insulating liquid 19 and the central axis O etc. figure 1 Same as described in Example 1 shown. The states described by A and B also represent the position of the conductive liquid when no power is applied and a certain voltage is applied, respectively.

[0049] In this example, the ring is integrated with the cavity to form a cavity 31 with a central through hole, which simplifies the fixing of the ring. In the chamber 31, several small through holes 33 are distributed around the central through hole, so that the upper and lower parts of the insulating liquid 19 communicate with each other. The bottom surface is given a hydrophilic treatment 32 and the rest is given a hydrophobic treatment. The transparent electrode 13, the insulating dielectric film 14 and the hydrophobic film 18 on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com