Polyester resin composition

A technology of resin composition and polyester, applied in the field of polyester resin composition, can solve the problems of loss of commodity value, inability to shape, inability to impart toughness, etc., achieve high toughness and light discoloration resistance, maintain surface smoothness, The effect of suppressing the production of exudate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-2

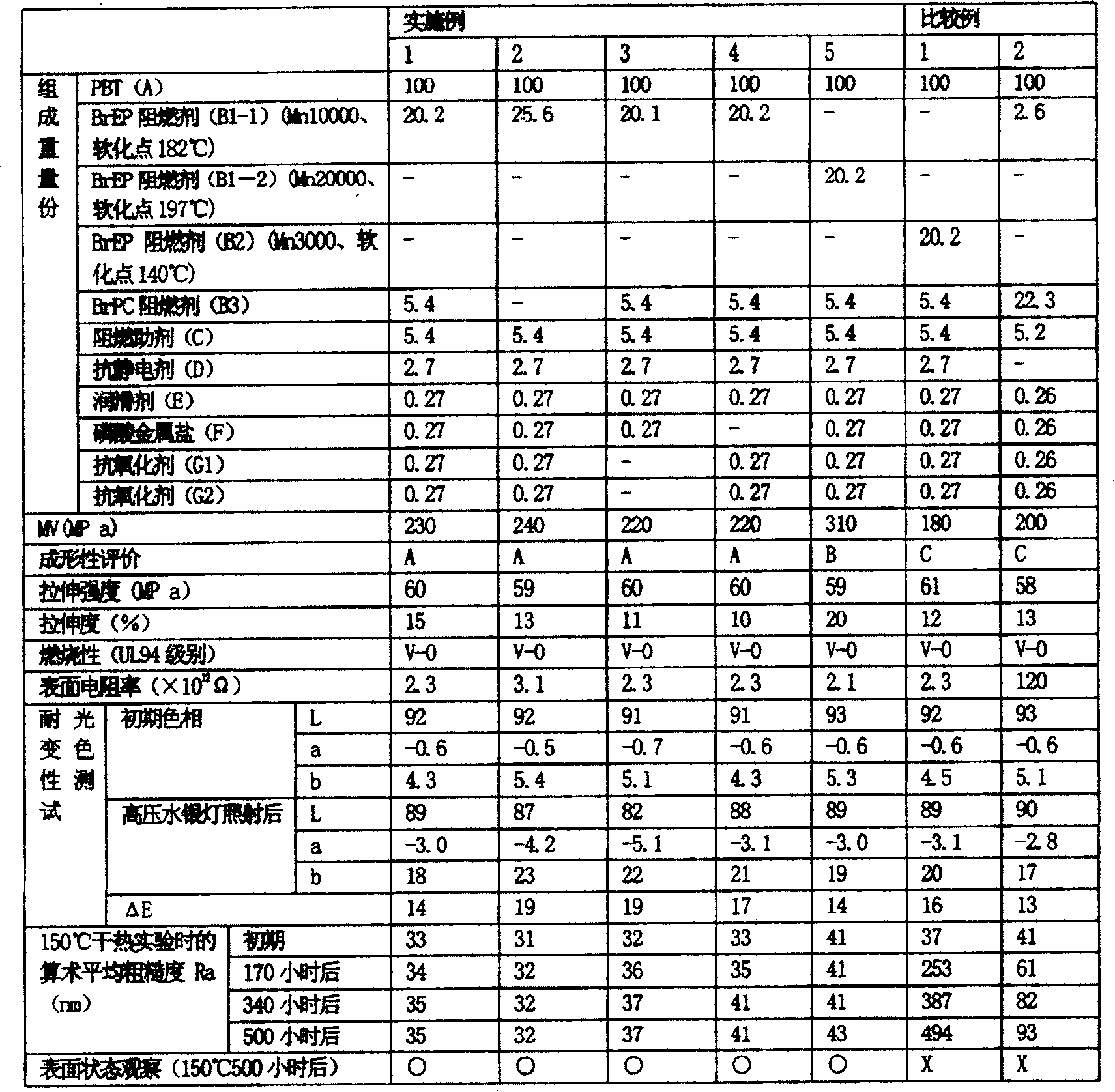

[0167] The above-mentioned various components were mixed according to the ratio shown in Table 1, and a twin-screw extruder was used for melt kneading to prepare a pellet-shaped resin composition. Thereafter, test pieces were produced by injection molding using the pellets, and the characteristics related to the above-mentioned items were evaluated. Table 1 shows the results.

[0168] Table 1

[0169]

[0170] As can be seen from Table 1, the resin compositions of Examples 1-5 maintain the required flame retardancy, antistatic properties, high fluidity (forming properties), mechanical properties (toughness) and light discoloration resistance, and no bleeding when annealed at 150°C. Especially for the resin composition of Examples 1-5, the elongation is 10% or more, and the toughness is also excellent. On the other hand, the resin compositions of Comparative Examples 1 and 2 showed significant bleeding when annealed at 150° C., and were not suitable for next-generation lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com