Metal mold type gravity casting die for cast of tin bronze, and casting method

A technology of gravity casting and metal moulds, which is applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of tin bronze sand casting environmental pollution, low production efficiency, and low efficiency, so as to reduce serious energy consumption and prolong service life , The effect of cleaning the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

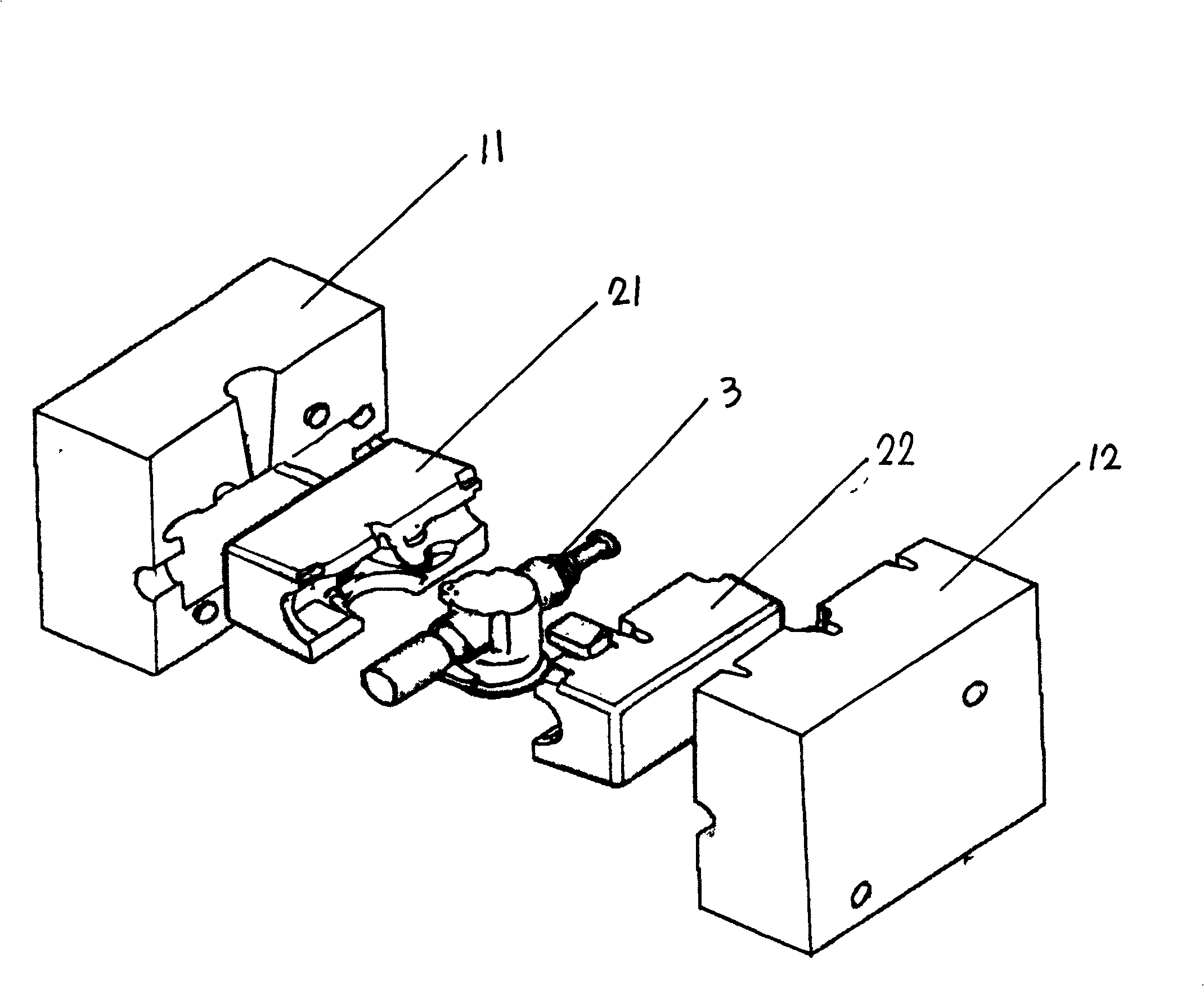

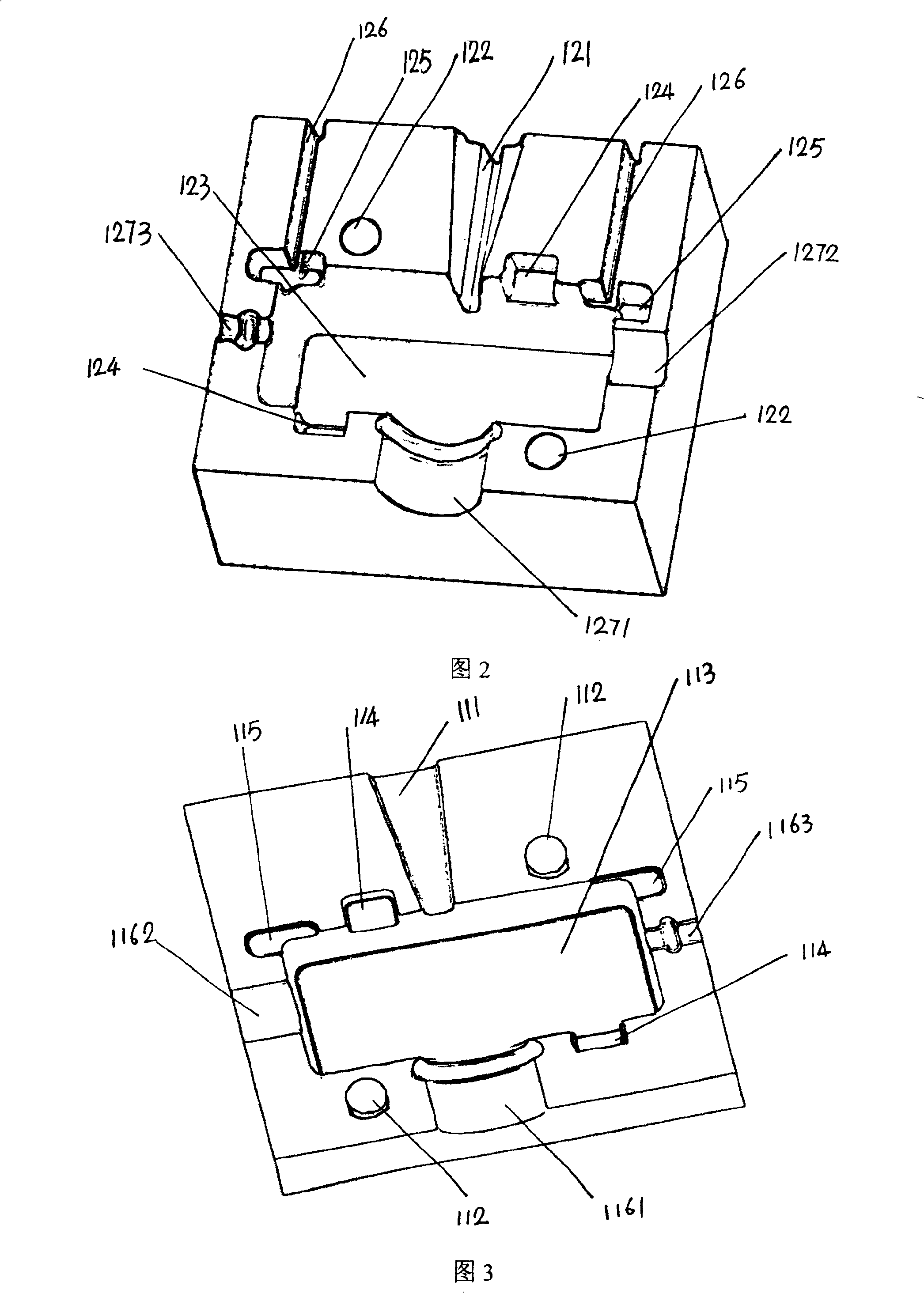

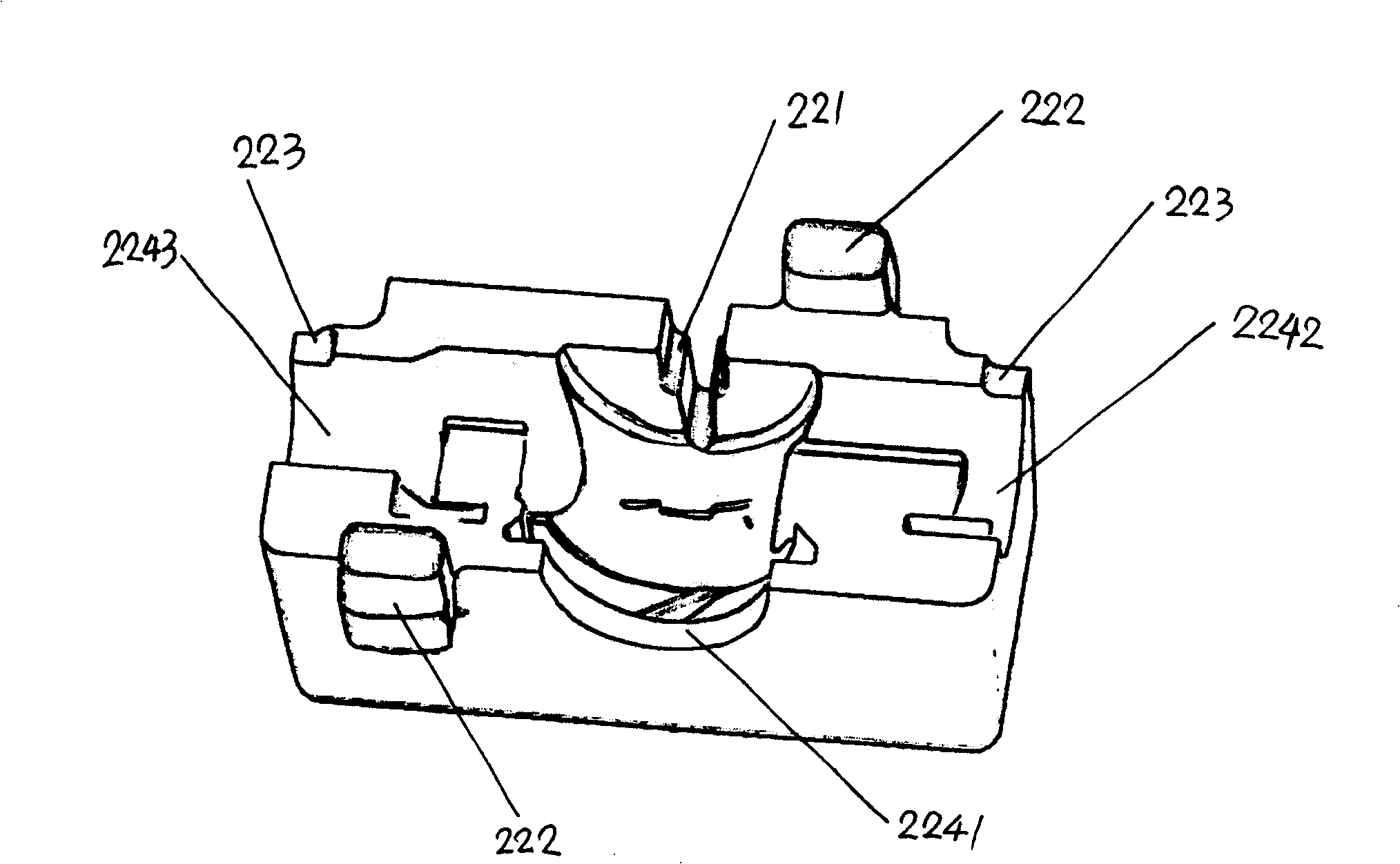

[0036] figure 1 , Figure 2, Figure 3, Figure 4 , Figure 5 , Image 6 It is an embodiment of a tin bronze valve body casting of the tin bronze casting gravity casting mold and casting method of the present invention. The following describes this embodiment in detail.

[0037]Metal mold 1 comprises fixed metal mold lower mold 11 and movable metal mold upper mold 12, please see Fig. 2, and Fig. 2 is the metal mold upper mold schematic diagram of the gravity casting method of tin bronze casting of the present invention. The metal mold upper mold 12 is provided with a metal mold upper mold sprue 121, two metal mold upper mold positioning sleeves 122 corresponding to the metal mold lower mold positioning pins 112, and external molding sand matching the external shape of the external sand core upper core 22. The upper core positioning groove 123 on the core, the upper core positioning groove 124 on the external sand core of the two metal molds, and the two metal molds connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com