Controllable bi-circulating hot-pipe system

A double-circulation, heat pipe technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems that the use effect is not as good as the one-piece heat pipe, insufficient working fluid delivery force, uneven liquid separation, etc., to achieve convenient and continuous adjustment and control, simplify the internal structure, and solve the effect of insufficient conveying force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

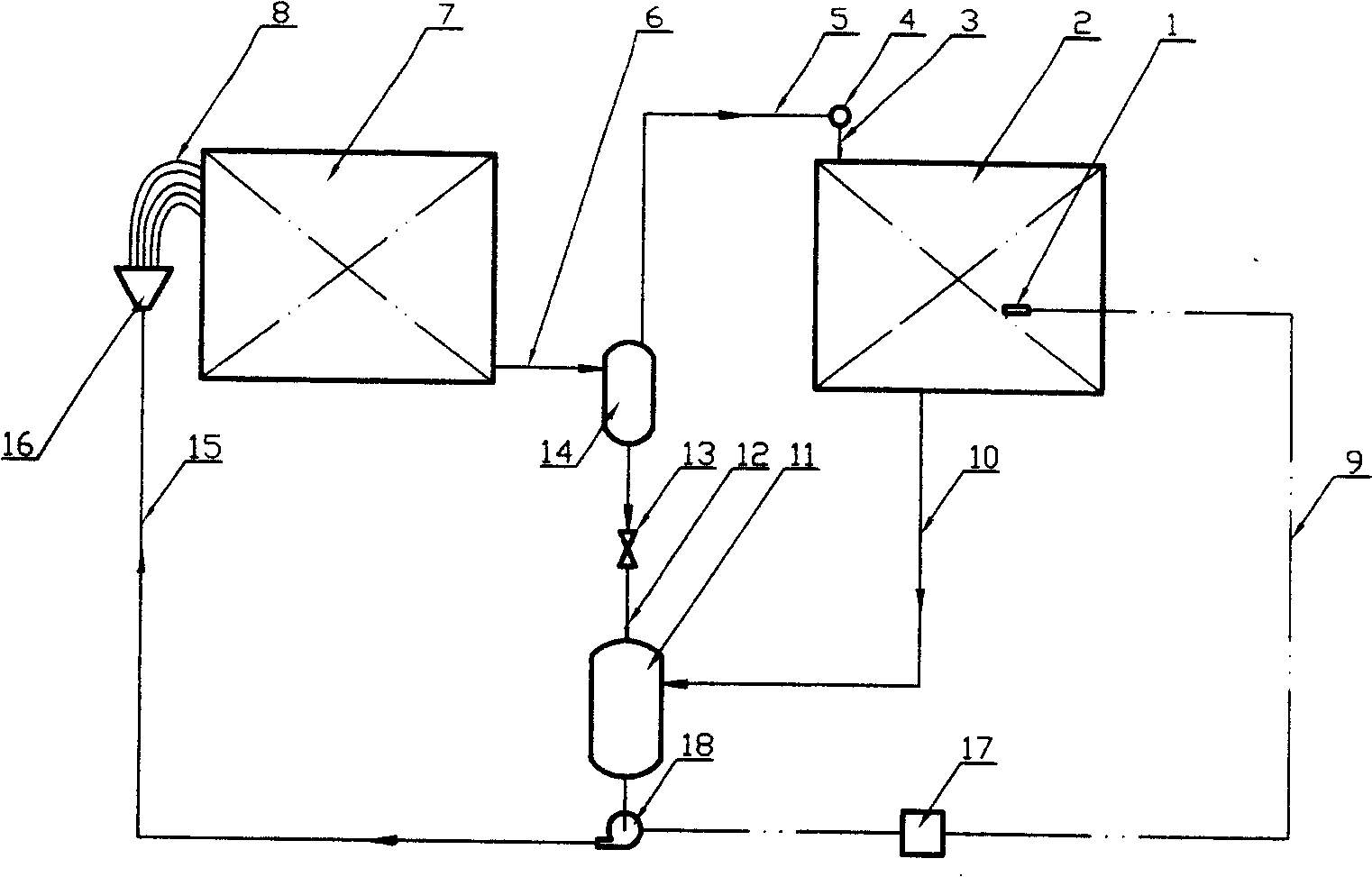

[0033] Embodiment 1: It is the structure and working process of the first kind of embodiment of the present invention, and its main components include evaporator 7 and condenser 2; The condensate liquid supply and distribution subsystem composed of the distribution tube bundle 8 of the length; the gas-liquid two-phase flow and separation subsystem composed of the two-phase flow delivery tube bundle 6 and the gas-liquid separator 14; , the gas-phase conveying and distributing subsystem composed of the gas-phase working medium main pipe 4 and the uniform gas-distributing pipe 3; it is composed of a pressure regulating valve 13, a gas-liquid separator liquid conveying pipe 12, a condenser condensate conveying pipe 10 and a liquid storage tank 11 Liquid phase collection and storage subsystem; heat exchange control subsystem composed of temperature sensor (or temperature sensing package) 1 , temperature signal transmission line 9 and temperature controller 17 . The above-mentioned ...

Embodiment 2

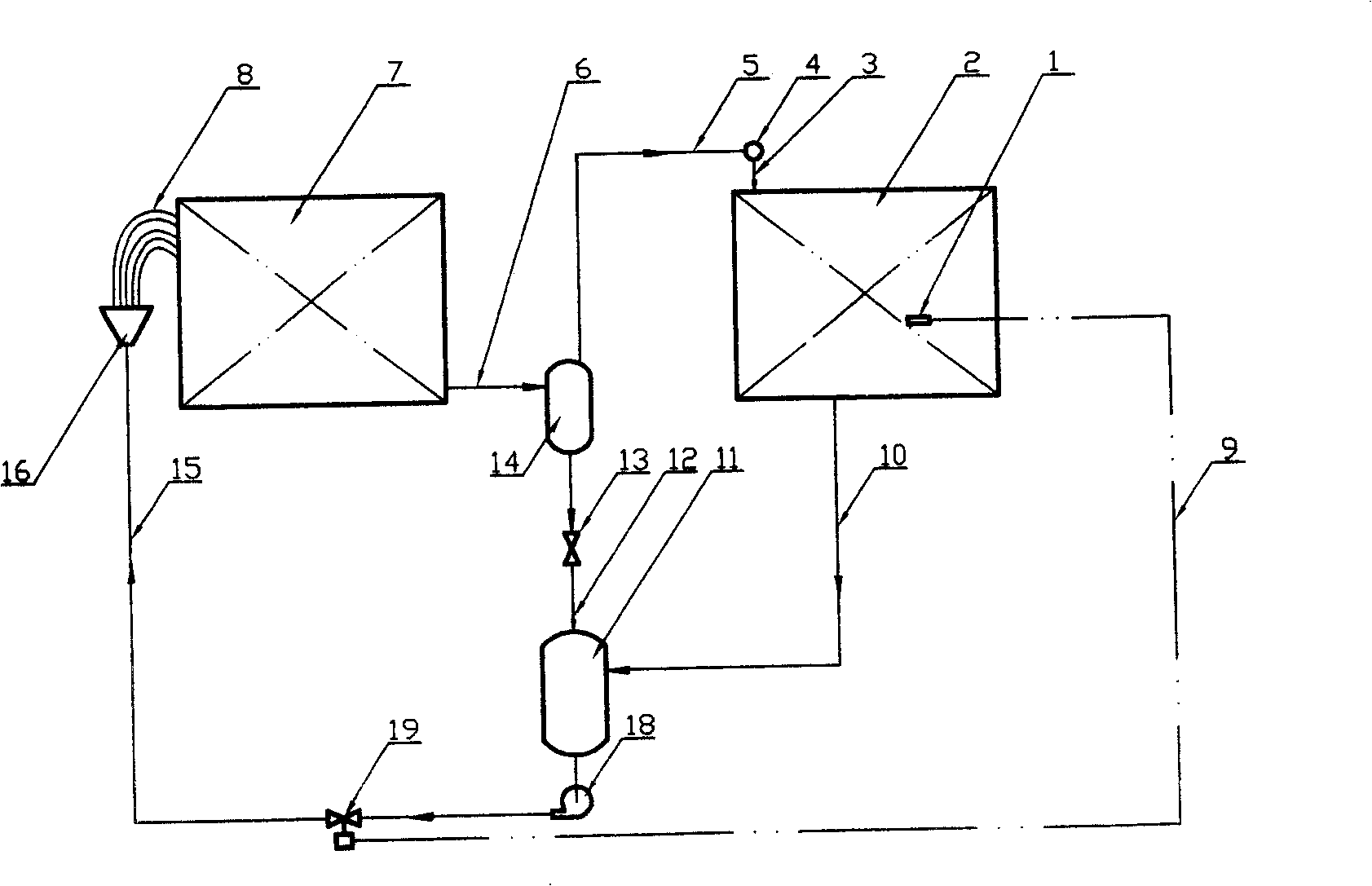

[0035] Embodiment 2: It is the structure and work flow of the second embodiment of the present invention, its evaporator 7 and condenser 2 and condensate liquid supply and distribution, gas-liquid two-phase flow and separation, gas phase transportation and distribution, and liquid phase collection The four subsystems of storage and storage are exactly the same as in Embodiment 1, but the heat exchange control subsystem is different. Embodiment 1 adopts temperature controller 17 to control the rotating speed of solution circulating pump to realize the regulation of liquid working fluid flow, present embodiment is to install temperature regulating valve 19 on circulating solution delivery pipe 15, the temperature sensing package 1, The temperature signal transmission pipe 9 directly regulates the flow rate.

[0036] The starting and running process of this embodiment is the same as that of Embodiment 1.

Embodiment 3

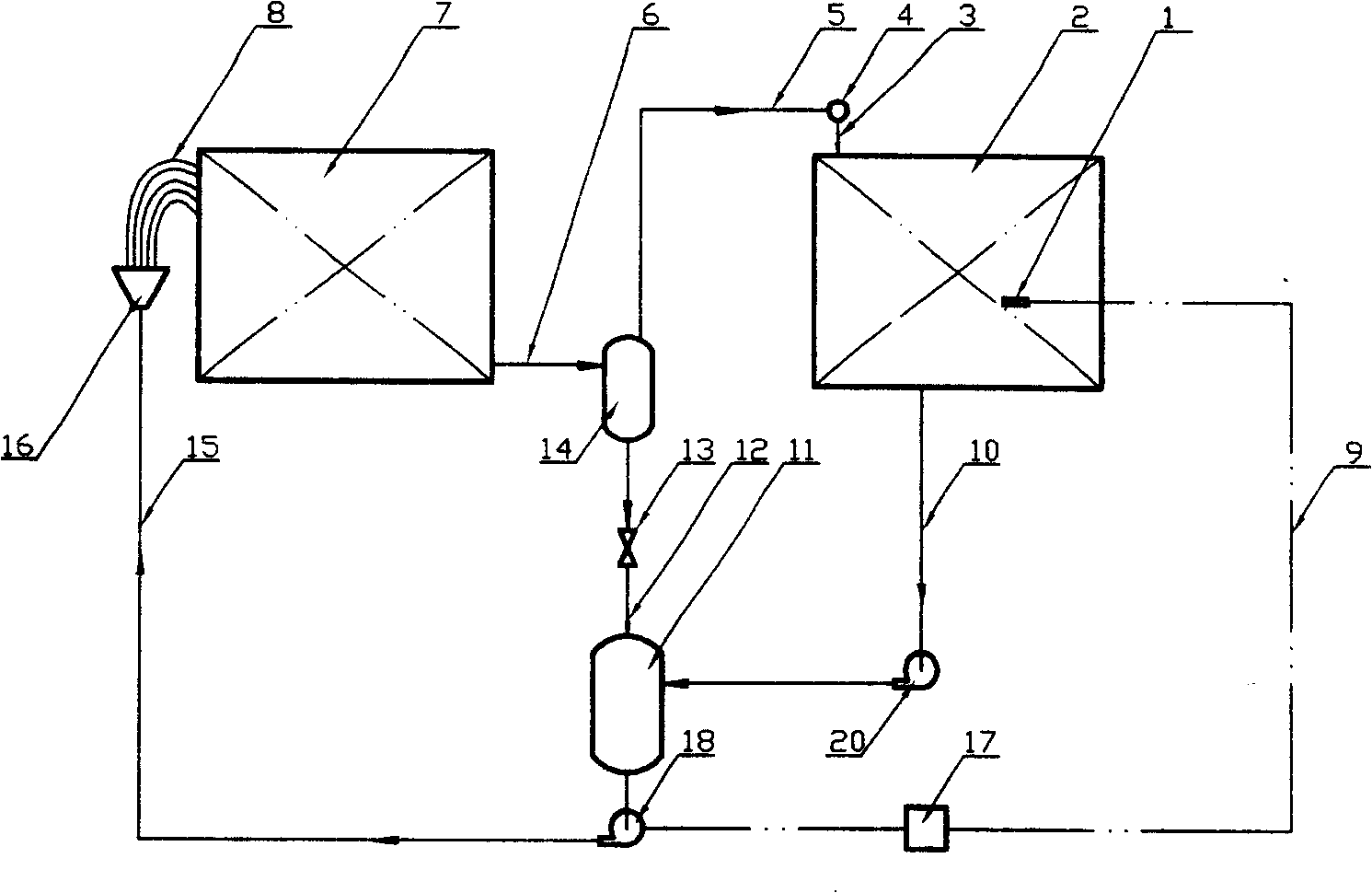

[0037] Embodiment 3: It is the structure and work flow of the third embodiment of the present invention, its evaporator 7 and condenser 2 and condensate liquid supply and distribution, gas-liquid two-phase flow and separation, gas phase transportation and distribution, and heat exchange The control of the four subsystems is exactly the same as in Example 1, but the liquid phase collection and storage are different. In Embodiment 1, the condensate of the condenser 2 flows directly into the liquid storage tank 11 by gravity, so the installation height of the liquid storage device must be lower than the lowest point of the condenser. Adding a solution pump 20 on top allows the installation height of the condenser 2 to be lower than that of the liquid receiver 11, making the installation and arrangement of the condenser more flexible.

[0038] The start-up and operation process of this embodiment is the same as that of embodiment 1. After the condensate is formed in the condenser,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com