Organic light-emitting diode and display

A technology of light-emitting diodes and organic light-emitting layers, applied in electroluminescent light sources, light sources, electric light sources, etc., can solve problems such as panel temperature rise, current unevenness, and characteristic deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

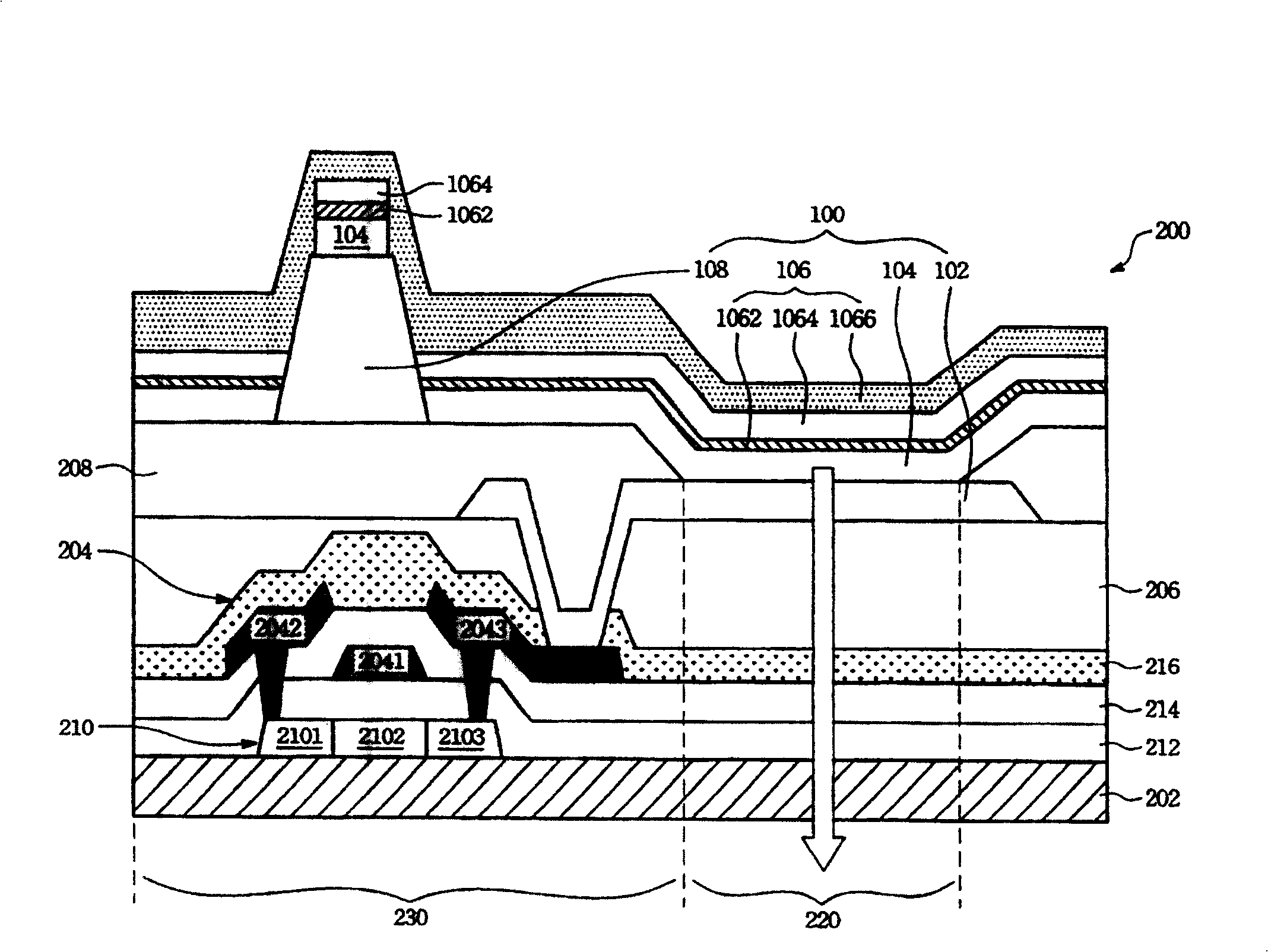

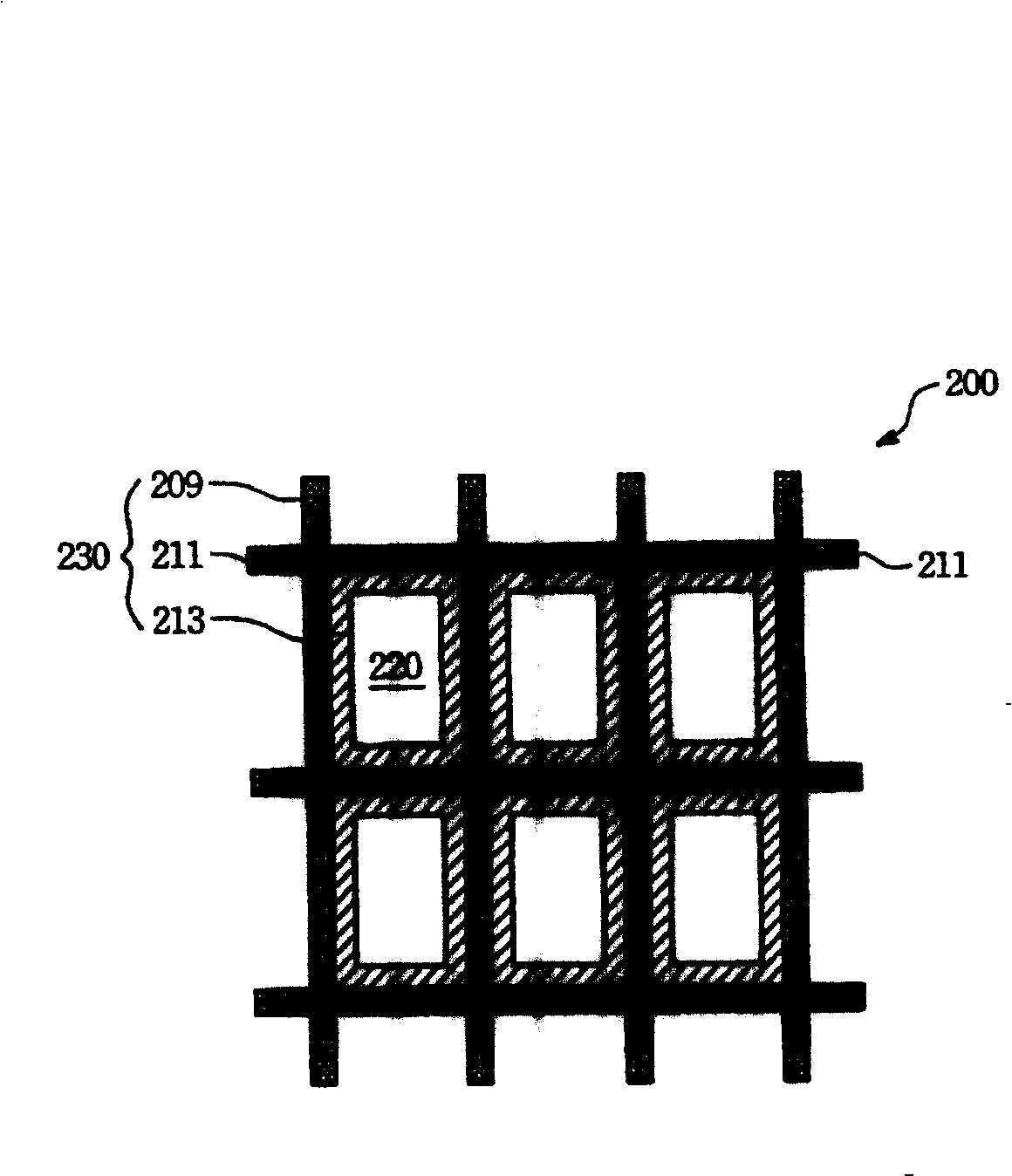

[0032] The "organic light-emitting diode and its display" of the present invention will be described in detail in conjunction with the icons, and the preferred embodiments will be described as follows:

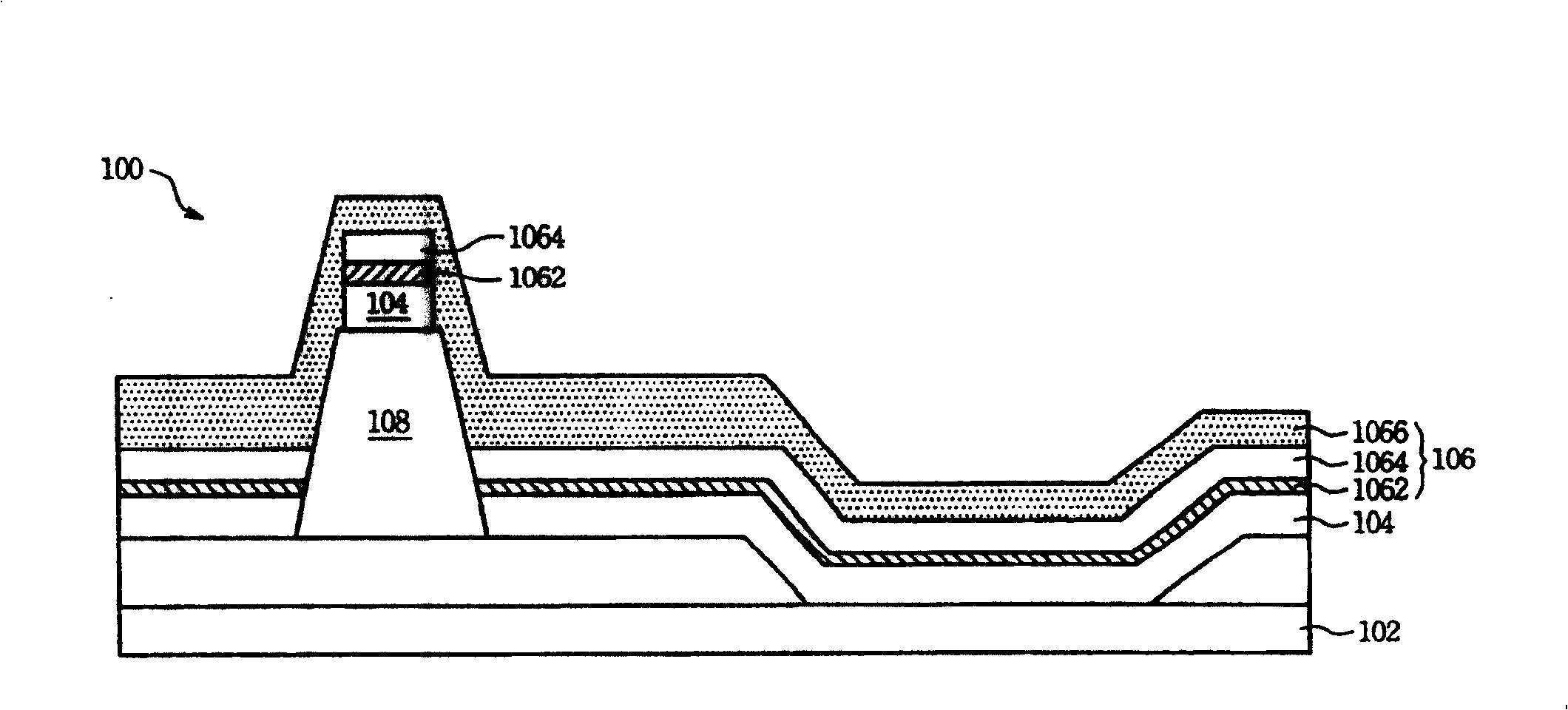

[0033] Please refer to figure 1 , is the organic light emitting diode of the present invention. The organic light emitting diode 100 includes a transparent electrode 102 , an organic light emitting layer 104 and an antireflection electrode 106 . The organic light-emitting layer 104 is located between the transparent electrode 102 and the anti-reflection electrode 106 and includes a low-molecular organic material or a high-molecular organic material.

[0034] The anti-reflection electrode 106 includes a first conductive layer 1062 , a second conductive layer 1066 and a non-metal layer 1064 . The non-metallic layer 1064 is sandwiched between the first conductive layer 1062 and the second conductive layer 1066 . The first conductive layer 1062 is located between the organic li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com