Method for preparing piezoelectric ceramic ball shell

A technique of piezoelectric ceramics and a manufacturing method, which is applied in the field of bonding piezoelectric ceramic hemispherical shells into piezoelectric ceramic spherical shells, can solve problems such as uneven wall thickness of spherical shells, and achieve a good symmetry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] As an example, for SR 外 =35mm; the manufacturing method of the piezoelectric ceramic spherical shell with wall thickness t=3mm is as follows:

[0015] (1) Select the CB1125-98 piezoelectric ceramic powder that has been batched, pre-fired, and finely ground, and dried for subsequent use;

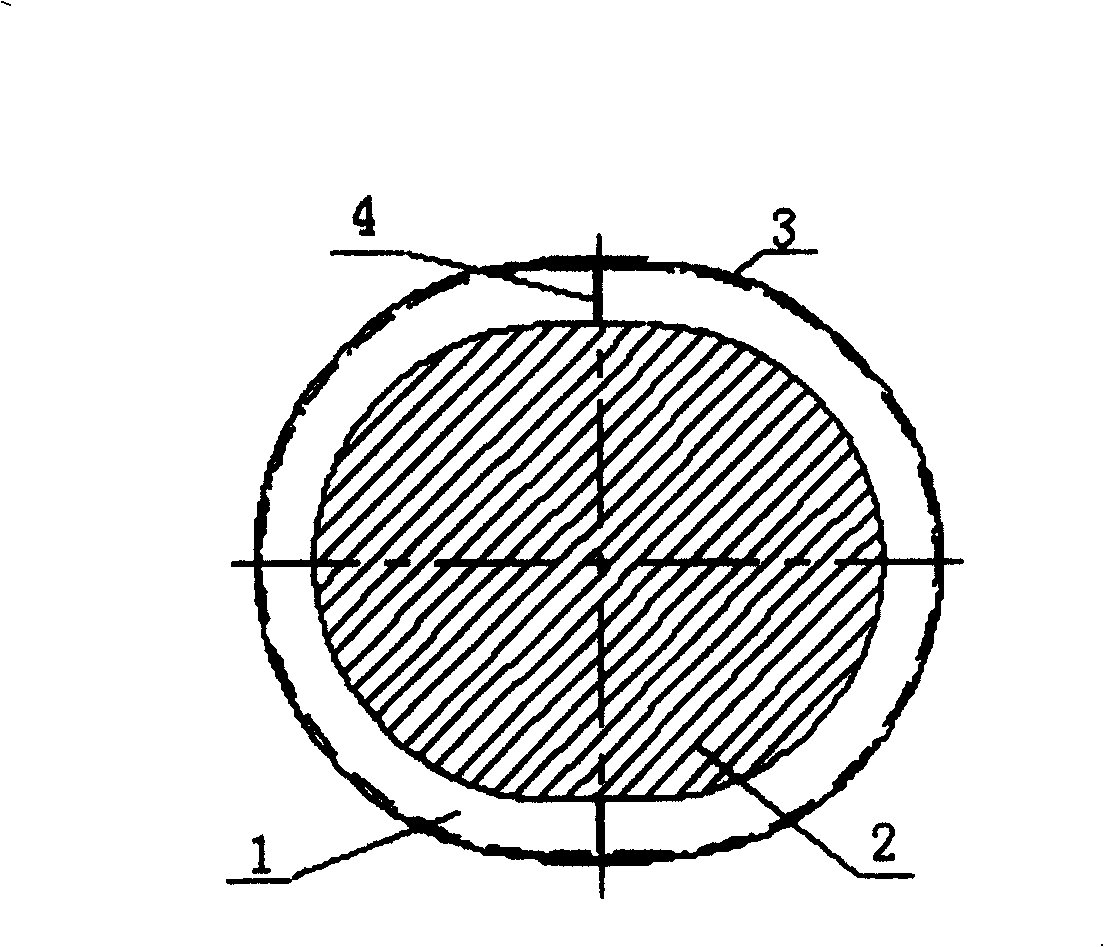

[0016] (2) The piezoelectric ceramic powder 1 is installed between the hydrostatically formed metal inner core 2 and the polyvinyl chloride elastic mold 3, and the piezoelectric ceramic powder is divided into two hemispherical shells from the middle by a paper separation ring 4;

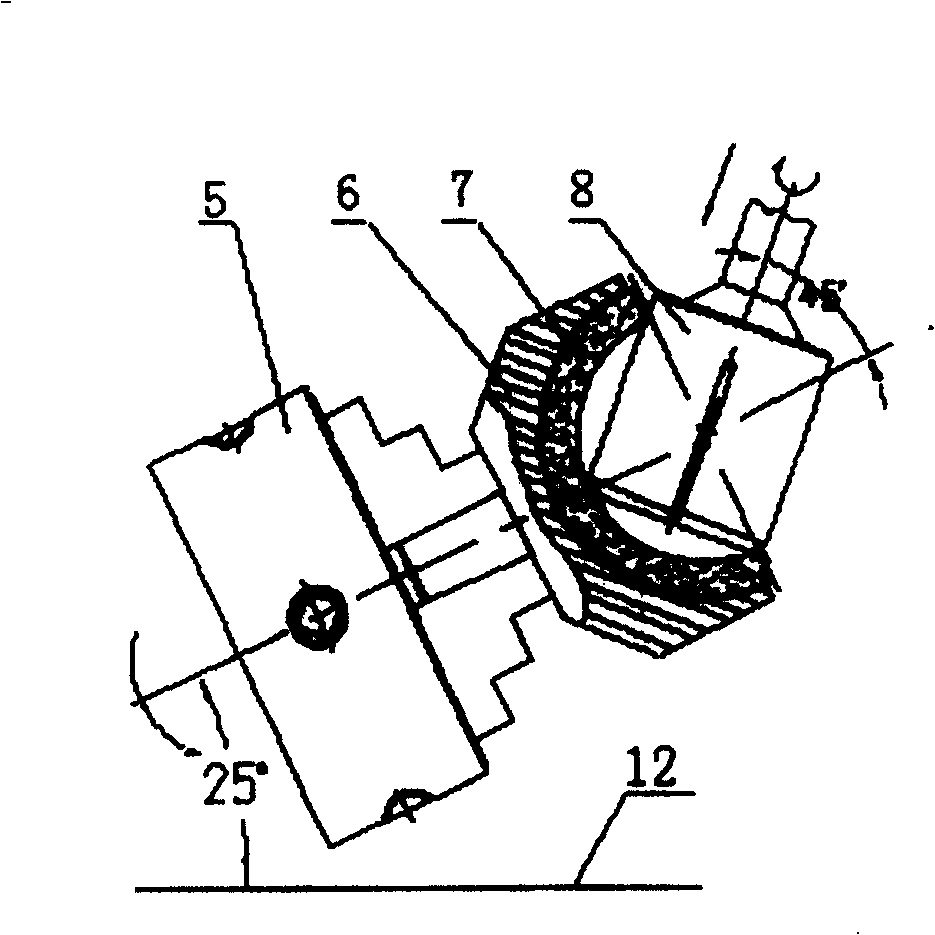

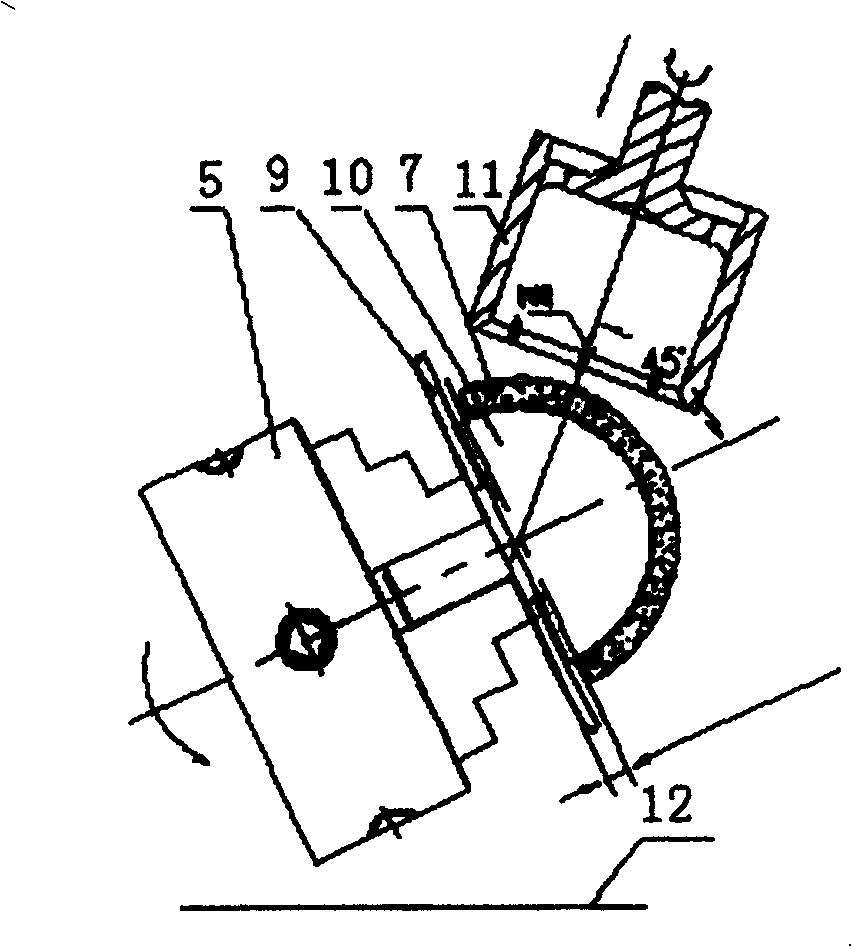

[0017] (3) Wrap several layers of high-density polyethylene food fresh-keeping bags outside the polyvinyl chloride elastic mold equipped with piezoelectric ceramic powder and seal them, put them into the oil medium of the hydrostatic pressure forming container, and form them with a pressure of 200 MPa;

[0018] (4) After forming, the hemispherical shell is sintered at a temperature of 1300-1350°C to make a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com