Method for preparing dual hole polarized optical fibre phase regulator and products thereof

A phase modulator and optical fiber technology, applied in the field of optical information, can solve problems such as difficulties, and achieve the effects of small insertion loss, reduced loss, and simple coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

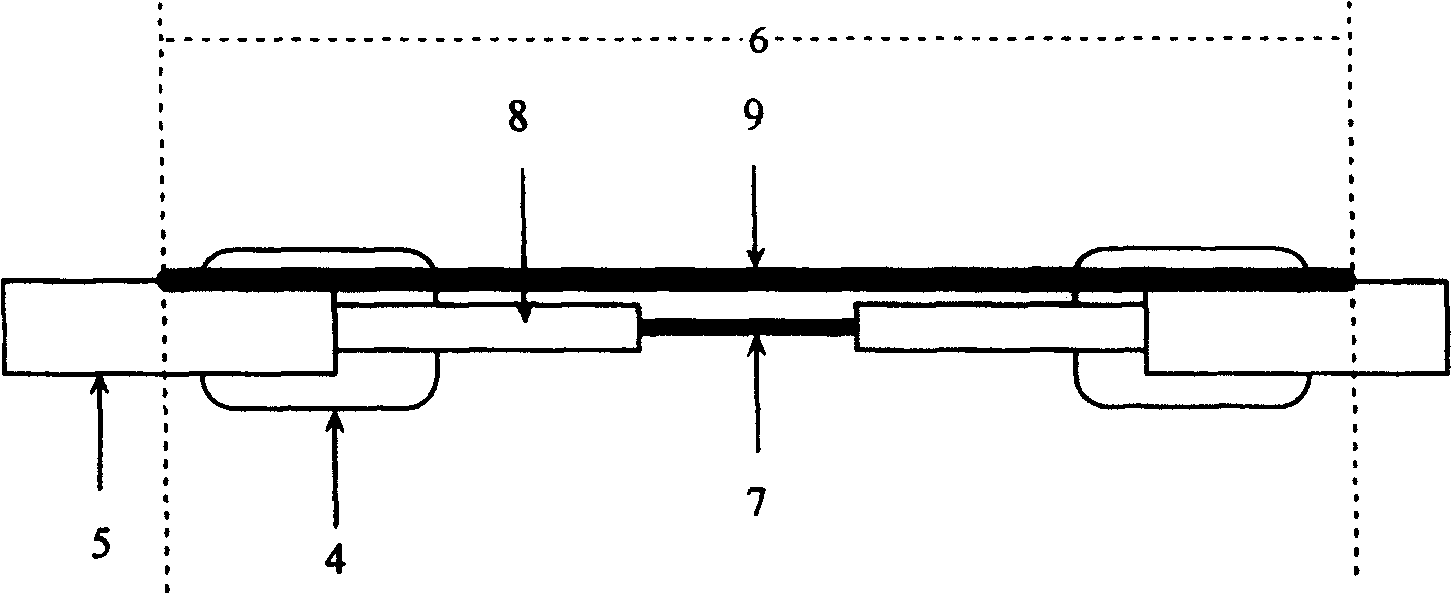

[0024] The present invention will be described in detail below through preferred embodiments in conjunction with the accompanying drawings.

[0025] In this example, the double-hole optical fiber used was manufactured by the 46th Research Institute of China Electronics Technology Group Corporation, with a core size of 6.6×7.9 μm 2 (Oval), the aperture is about 28 microns, and the loss is 0.4dB / m. Its cross-sectional view is shown in Figure 1(a).

[0026] The electrode material must meet the following requirements: good electrical conductivity; sufficiently thin and uniform in thickness; high hardness and not easy to bend. Therefore, tungsten wire is selected as the electrode in this embodiment. A large number of experiments have proved that the tungsten wire will become very soft when the diameter is about 20 microns, which is not suitable for perforation. In this embodiment, the tungsten wire used is a commercially available tungsten wire with a diameter of 28 microns.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com