Multiple molecule contacting catalytic reaction apparatus and method

A contact catalysis and reaction device technology, applied in the field of multi-molecular contact catalysis reaction devices, can solve problems such as poisoning, decrease in reaction activity, catalyst poisoning, etc., and achieve the effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

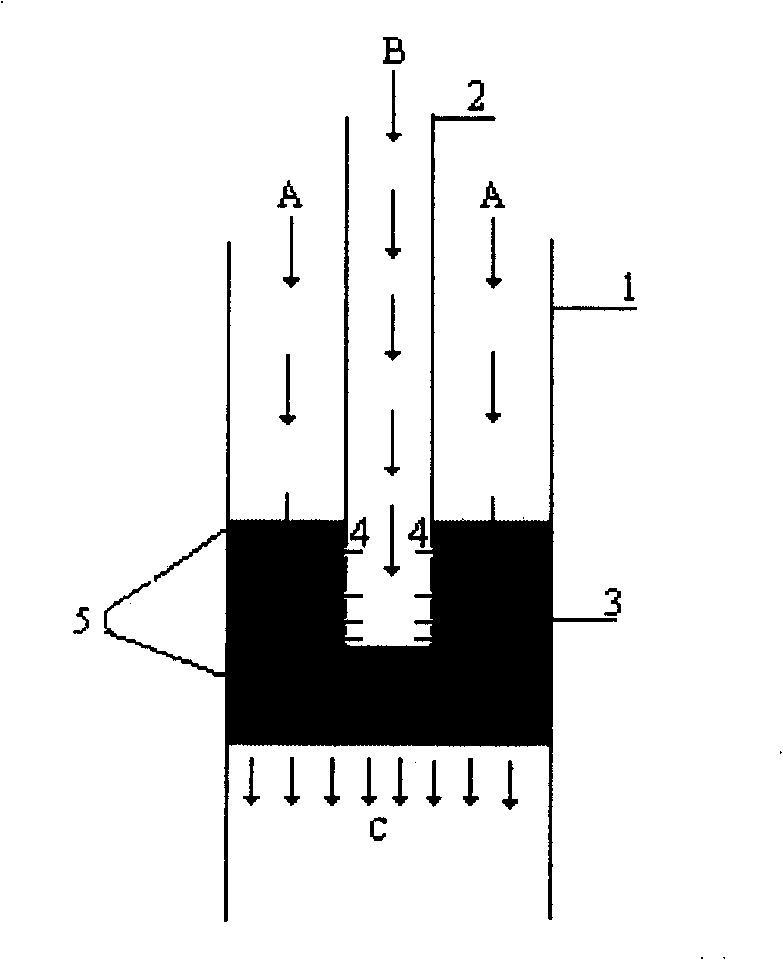

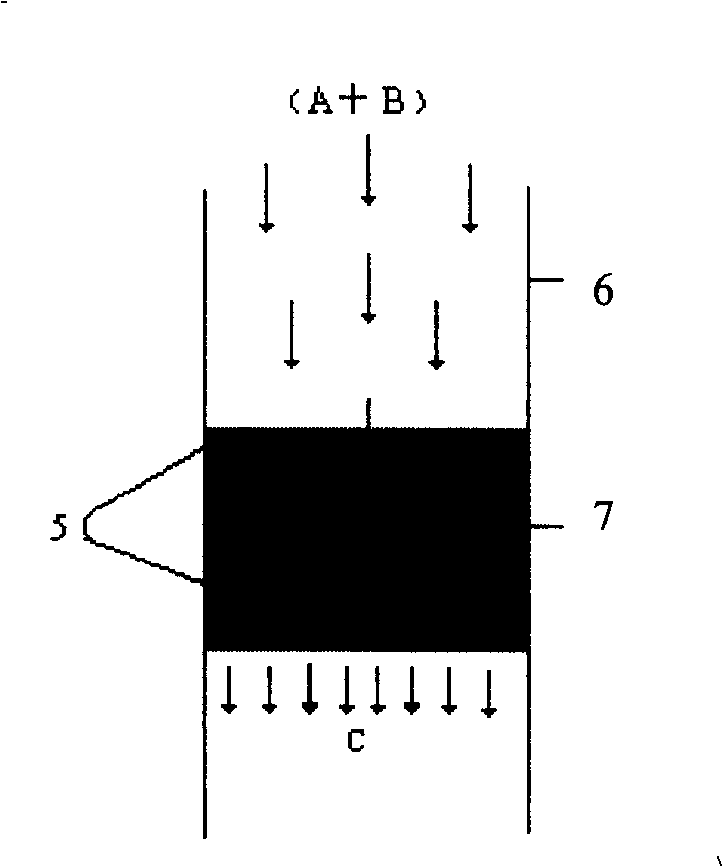

[0019] see figure 1 , the multi-molecular contact catalytic reaction device comprises a cylindrical reaction vessel 1, a material conduit 2 and a catalyst bed 3, the material conduit 2 is vertically arranged in the reaction vessel from the upper end of the reaction vessel 1, and the bottom of the material conduit 2 is fixed on On the catalyst bed 3, the catalyst bed 3 is located in the middle of the reaction vessel. At least two openings 4 are arranged on the conduit wall at one end of the catalyst bed, and the openings 4 are distributed densely at the top and sparsely at the bottom along the vertical direction of the material conduit 2, and distributed symmetrically in the horizontal direction; the diameter of the openings 4 is smaller than the catalyst particles.

[0020] Reaction with B 2 o 3 4.7% (wt) nickel-based catalyst, when loading the catalyst, a small amount of quartz sand or ceramic ring (ball) 5 is respectively installed at the upper and lower ends of the catal...

Embodiment 2~3

[0023] Adopt the polymolecular contact catalytic reaction device of embodiment 1 to react, change the hydrogen volume space velocity to be 15000h respectively - 1 and 45000h -1 , all the other reaction conditions are the same as in Example 1, and the ethylcyclohexane yield is listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com