Method for separating micro Nano material

A separation material, micro-nano technology, applied in the field of micro-nano materials, to achieve the effect of simple and easy reagents, less process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Separation of micro-nano materials with the same shape and different sizes of the same material.

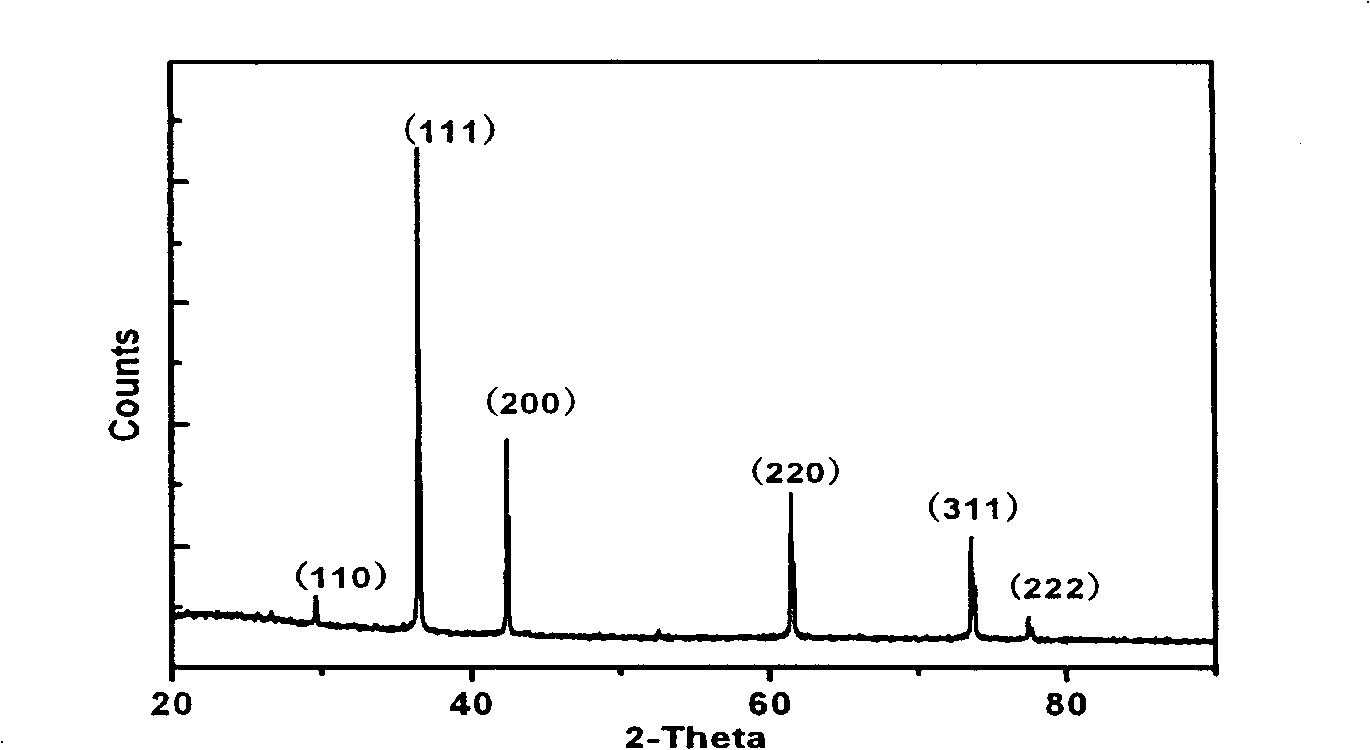

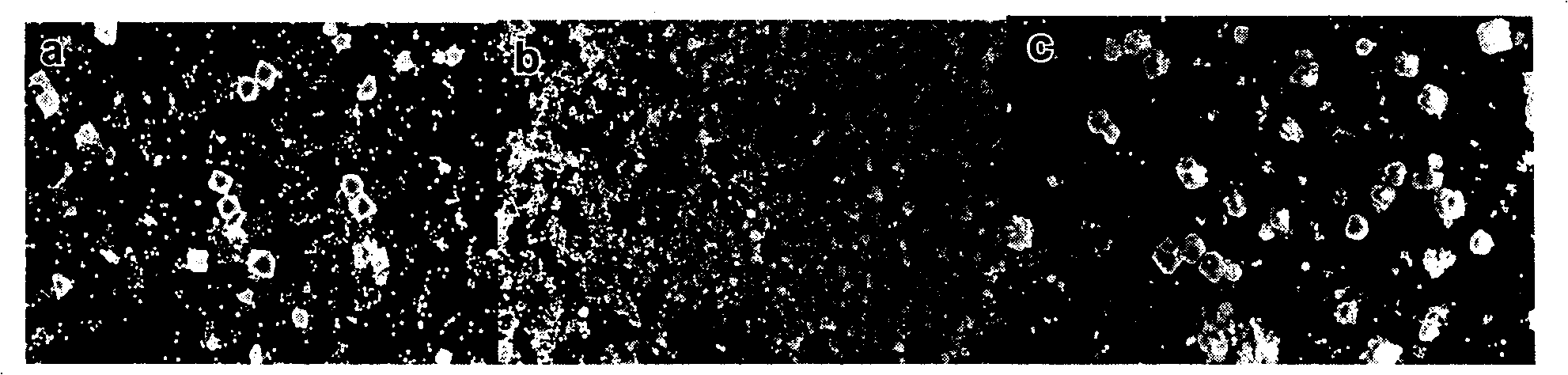

[0017] Get through XRD (see figure 1 ) and scanning electron microscopy (see figure 2 a) The characterized cuprous oxide sample is used as the sample to be separated, and 1 ml of n-amyl alcohol is added to 5 mg of the material to be separated, and ultrasonically dispersed to form a suspension.

[0018] Add 2.5ml of deionized water to the centrifuge tube, pipette 300μl of the above suspension and carefully add it to the centrifuge tube, so that the n-amyl alcohol suspension of the upper sample and the water in the lower layer form a liquid-liquid interface. Pipette 100 μl of ethanol into the centrifuge tube; put the centrifuge tube into the centrifuge and centrifuge at 2000rpm, the sample to be separated is divided into two parts: at the interface and at the bottom of the centrifuge tube; collect the interface (upper layer) and centrifuge tube For the sample a...

Embodiment 2

[0020] Example 2: Separation of micro-nano materials of the same material with different shapes.

[0021] Take 4mg of cuprous oxide sample prepared in the laboratory as the material to be separated, add 1ml of n-amyl alcohol to the material to be separated, and disperse it ultrasonically to form a suspension; add 2ml of deionized water to the centrifuge tube, and pipette 300μl Carefully add the above suspension into the heart tube, so that the n-pentanol suspension of the upper sample and the water in the lower layer form a liquid-liquid interface, pipette 50 μl of ethanol into the centrifuge tube; put the centrifuge tube into the centrifuge Centrifuged at 4000rpm, the sample to be separated was divided into two parts: at the interface and at the bottom of the centrifuge tube; samples at the interface (upper layer) and at the bottom of the centrifuge tube (lower layer) were collected.

[0022] The separated product was characterized by a scanning electron microscope to obtain ...

Embodiment 3

[0023] Example 3: Separation of nanowires with the same shape and different densities.

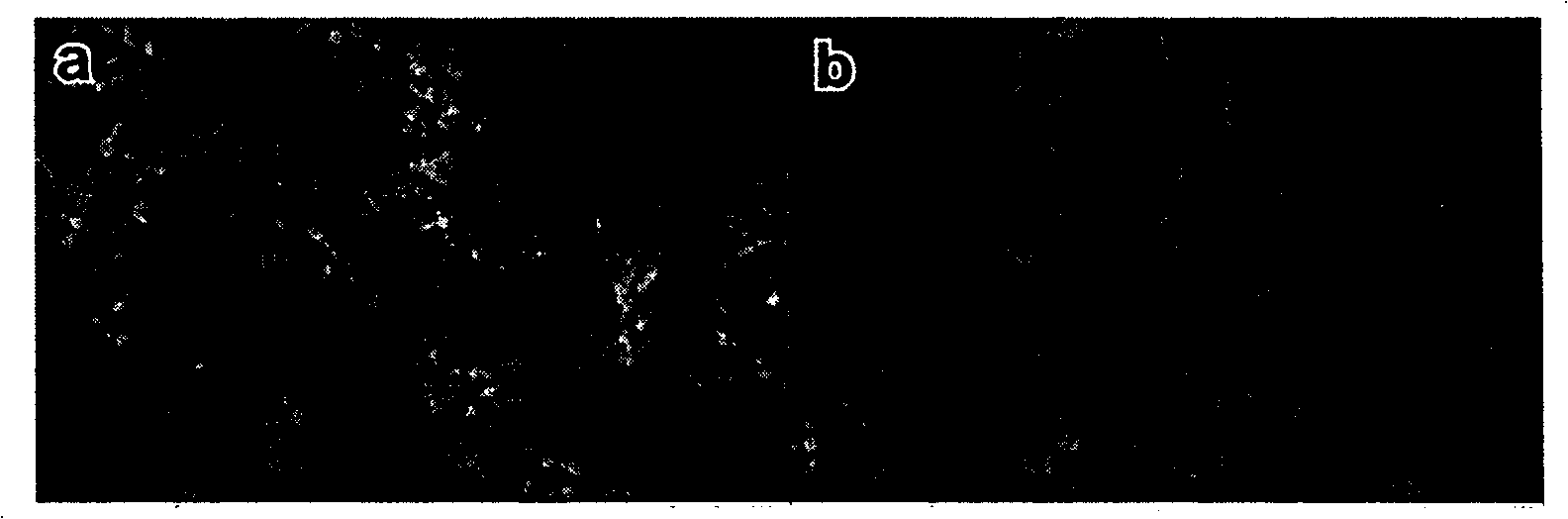

[0024] 1) Take 3 mg of silver nanowires prepared in the laboratory as the sample to be separated (see Figure 4 a, b, c), add 1ml of n-amyl alcohol to the sample to be separated, and ultrasonically disperse to form a suspension;

[0025] 2) Add 2.5ml of deionized water to the centrifuge tube, pipette 300μl of the above suspension and carefully add it to the heart tube, so that the n-amyl alcohol suspension of the upper sample and the water in the lower layer form a liquid-liquid interface. Pipette 75 μl of ethanol into the centrifuge tube;

[0026] 3) Put the centrifuge tube into the centrifuge and centrifuge at a speed of 4000rpm. The sample to be separated is divided into two parts: at the interface and at the bottom of the centrifuge tube;

[0027] 4) Collect the sample at the bottom (lower layer) of the centrifuge tube.

[0028] The collected samples were characterized by scanning e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com