Press filtration type water purification method and device therefor

A filter press and water purification technology, applied in the field of water treatment, can solve the problems of multiple filter layers, unsustainable water supply, complex structure, etc., achieve stable water quality, reduce land and construction investment, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

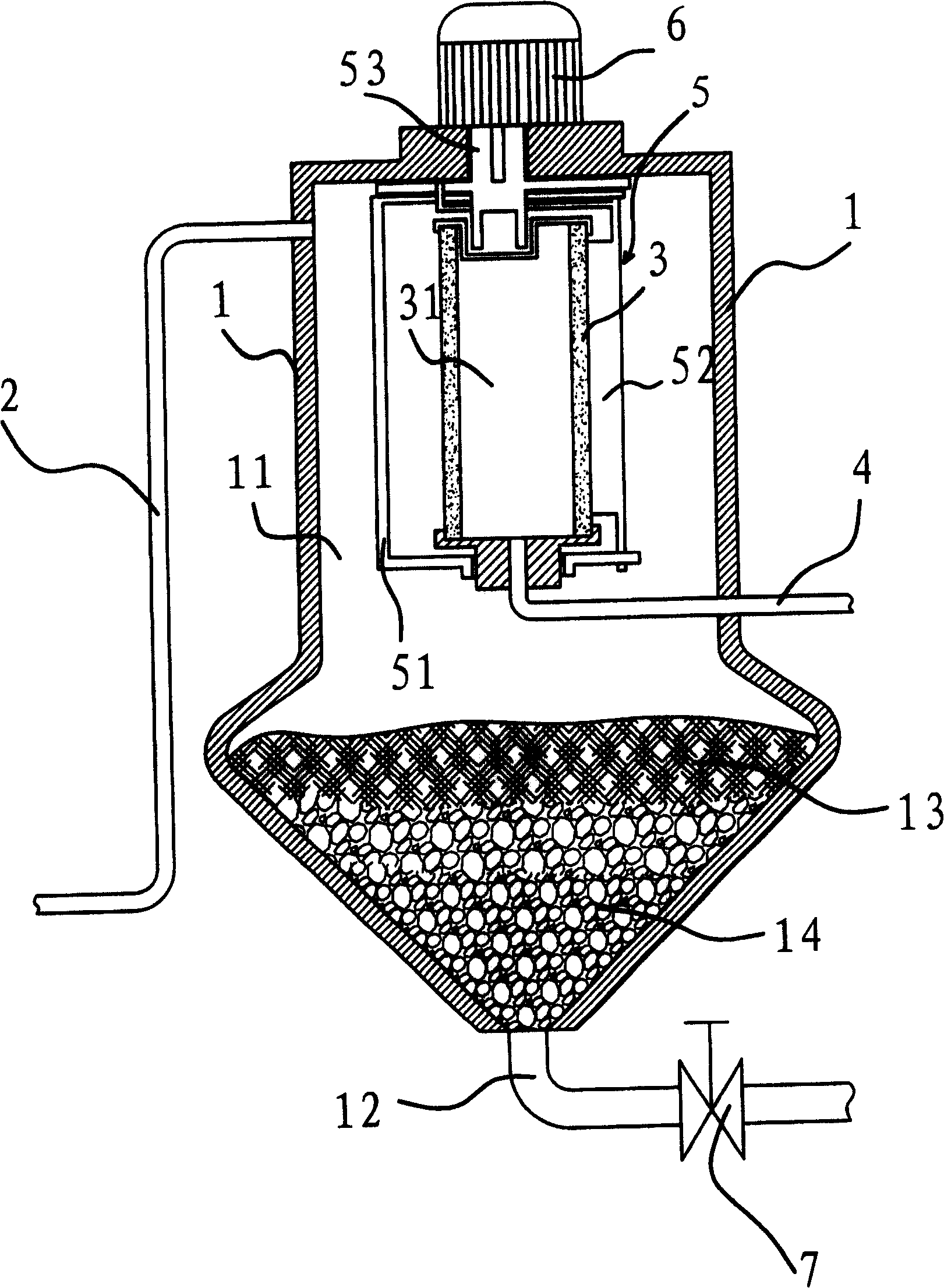

[0029] like figure 1 As shown, the filter press type water purification device is composed of a housing 1, a water inlet pipe 2, a filter element 3, a water outlet pipe 4 and a cleaning device 5 and other components.

[0030] The housing 1 is cylindrical and has a water inlet chamber 11 inside. The water inlet pipe 2 is connected to the upper part of the casing 1 and communicates with the water inlet chamber 11 . In this embodiment, the lower part of the shell 1 is conical, and its interior is divided into a solid-liquid separation and clarification zone 13 and a sludge zone 14 . The bottom of the sludge zone 14 directly communicates with the sewage outlet 12 .

[0031] In this embodiment, a valve 7 is installed at the sewage outlet 12 . The valve 7 is used to control the opening and closing of the sewage outlet 12 . Silt and dirt can be discharged outside directly through the sewage outlet 12.

[0032] like figure 1 As shown, in this embodiment, it is a filter core 3, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com