Optical fiber raster dynamic weigher for vehicle axle weight

A technology of fiber grating and dynamic weighing, which is applied in the direction of transmitting sensing components, measuring devices, and weighing with optical devices, which can solve the problems of large sensing mechanisms, low test accuracy, and slow test response, and achieve mature technology, Easy remote monitoring, easy maintenance and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

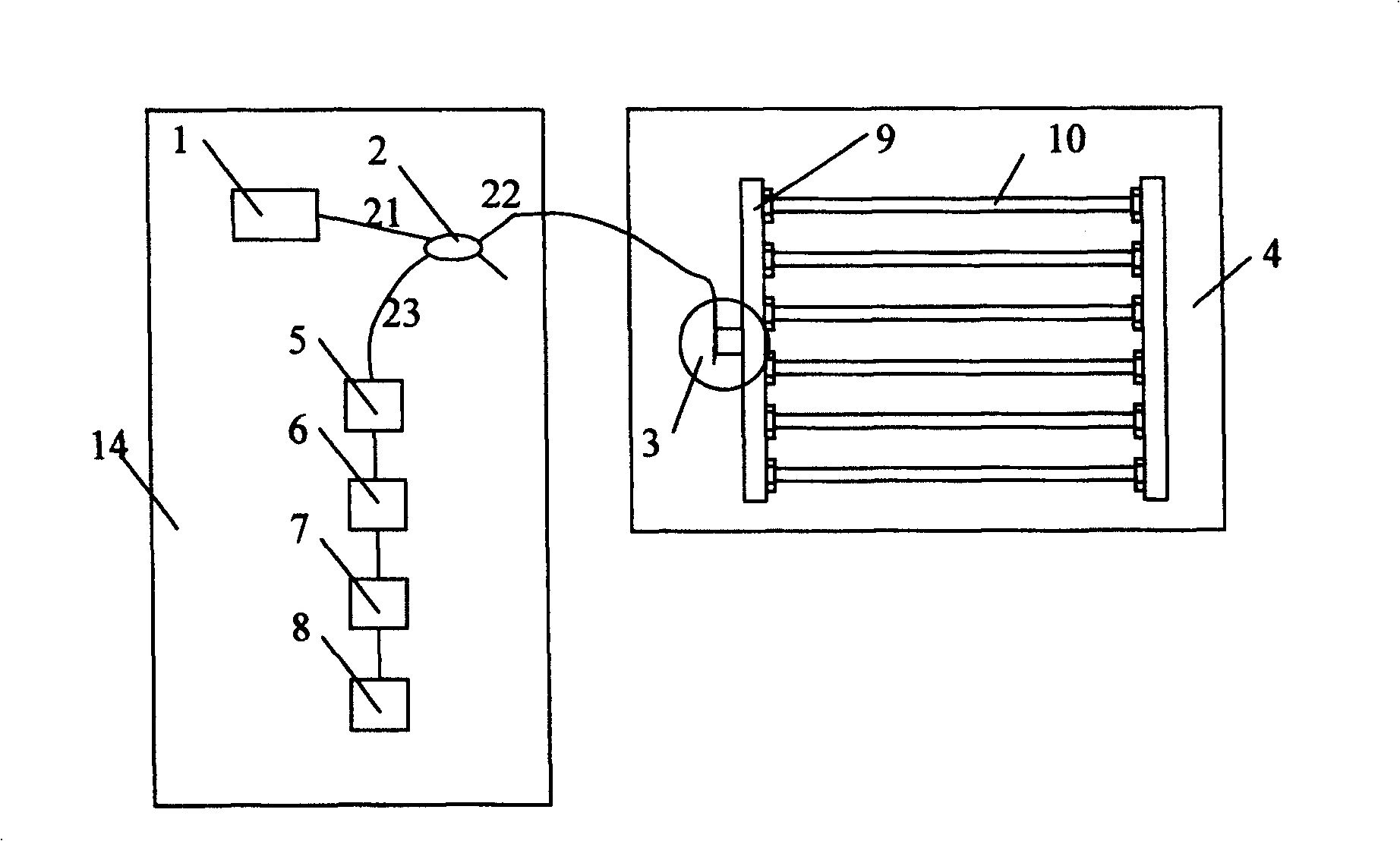

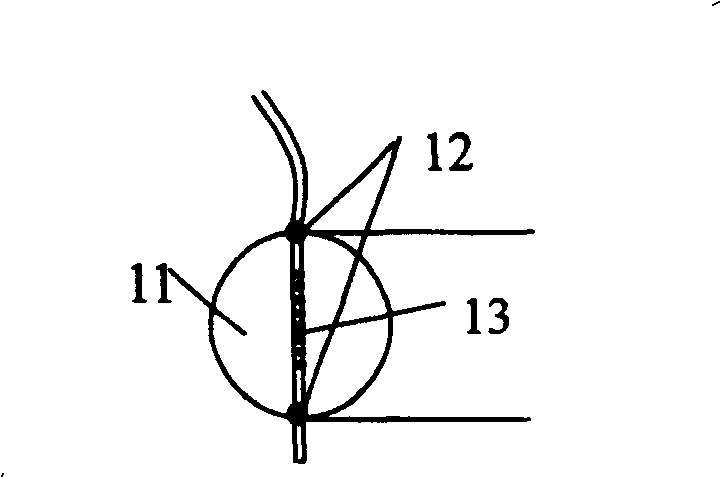

[0019] see first figure 1 and figure 2 As can be seen from the figure, the fiber grating vehicle axle load dynamic weighing device of the present invention is characterized in that it includes: a laser light source 1, the output end of the laser light source 1 is connected to the first end 21 of the fiber coupler 2, and the fiber coupler 2 The third end 23 of the fiber grating wavelength demodulation module 5 is connected, and then the photoelectric conversion module 6, the data acquisition device 7 and the industrial computer 8 are connected in series and arranged in the casing 14; the fiber grating pressure sensing head 3, the hydraulic valve The block 9 and the hydraulic hose array 10 form a hydraulic pressure sensing mechanism 4. The fiber grating pressure sensing head 3 uses epoxy polyester 12 to fix the two ends of the sensing grating 13 on a metal elastic diaphragm 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com