Air-assisted type spraying machine controller based on microcomputer

A technology of control device and sprayer, which is applied in the direction of injection device, computer control, emergency protection device with automatic disconnection, etc. It can solve the problems of nozzle blockage, coil voltage instability, fan frequent start and so on, and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

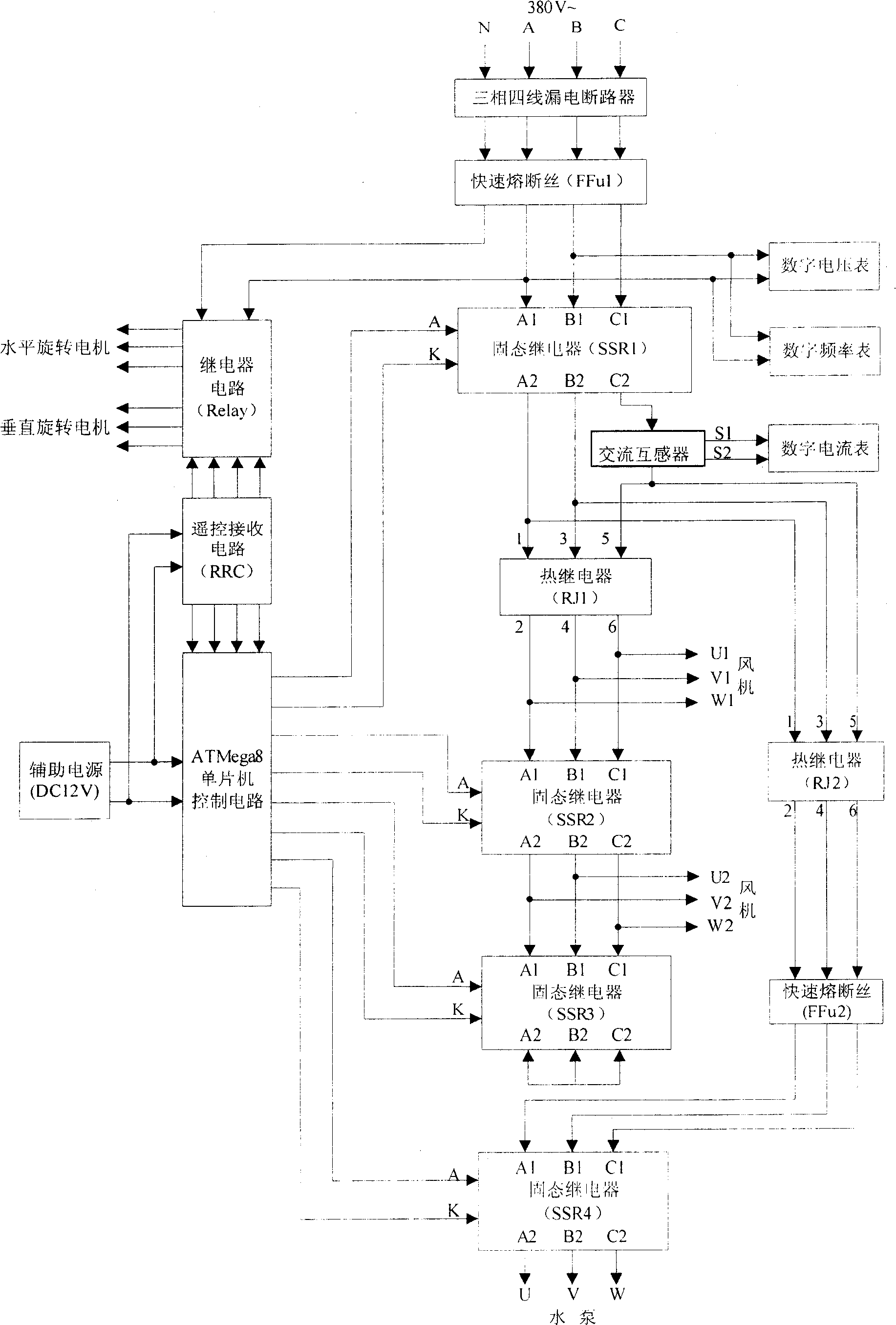

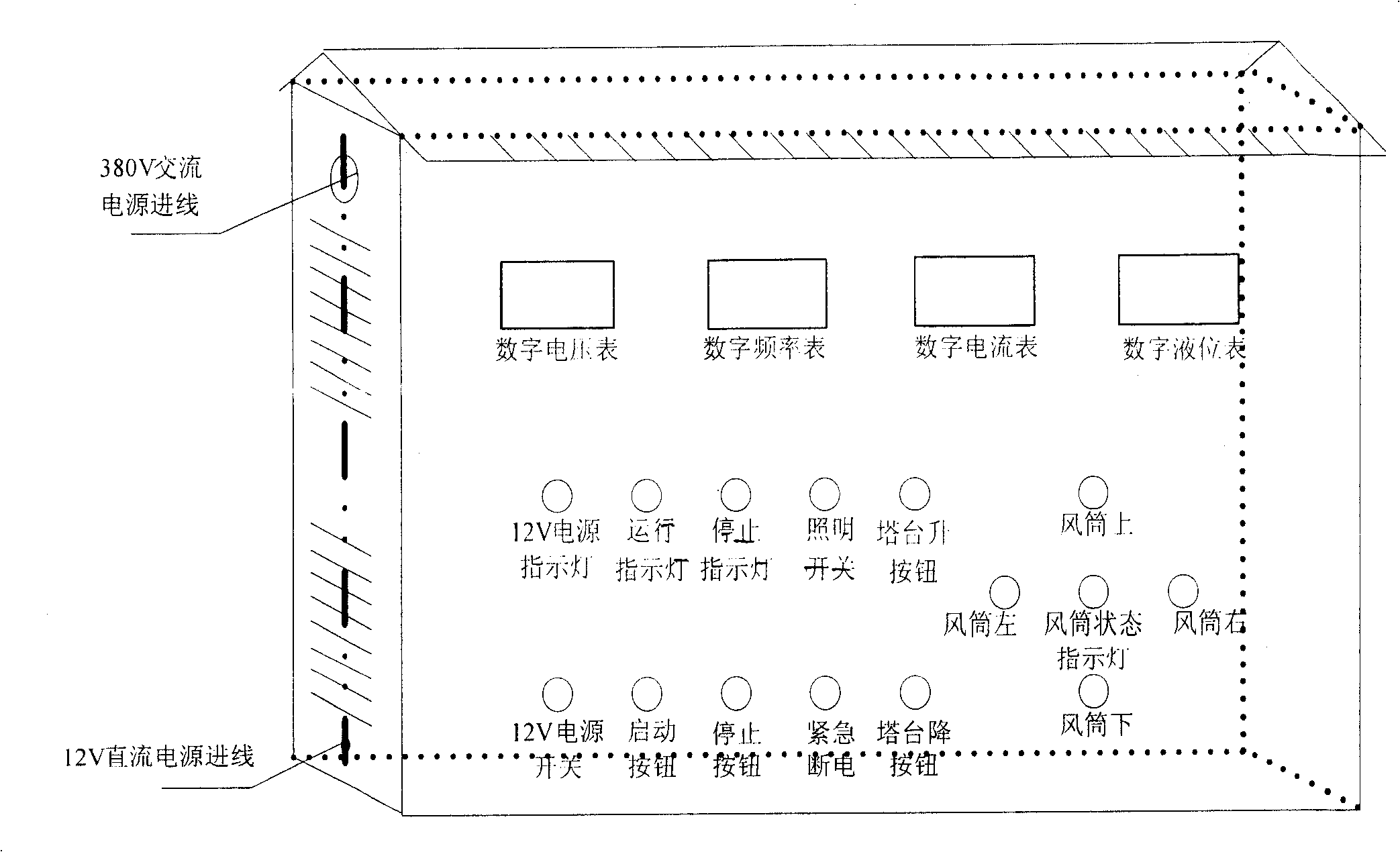

[0032] Such as figure 1As shown, the microcomputer-based air-supply sprayer control device is composed of ATMega8 single-chip control circuit, remote control receiving circuit (RRC), relay circuit (Relay), three-phase four-wire leakage circuit breaker, the first fast fuse FFu1, the second Two fast fuse FFu2, the first solid state relay SSR1, the second solid state relay SSR2, the third solid state relay SSR3, the fourth solid state relay SSR4, the first thermal relay RJ1, the second thermal relay RJ2, 12V DC auxiliary power supply and digital voltmeter , digital frequency meter, digital ammeter and AC transformer.

[0033] The MCU is connected to the auxiliary power supply, the remote control receiving circuit (RRC) and the control terminals of the first solid state relay SSR1, the second solid state relay SSR2, the third solid state relay SSR3, and the fourth solid state relay SSR4 respectively, and the three phase lines A of the three-phase power supply , B, C and neutral l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com