Stack organic electroluminescent cell and its manufacturing method

A technology for electroluminescent components and manufacturing methods, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, electro-solid-state devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

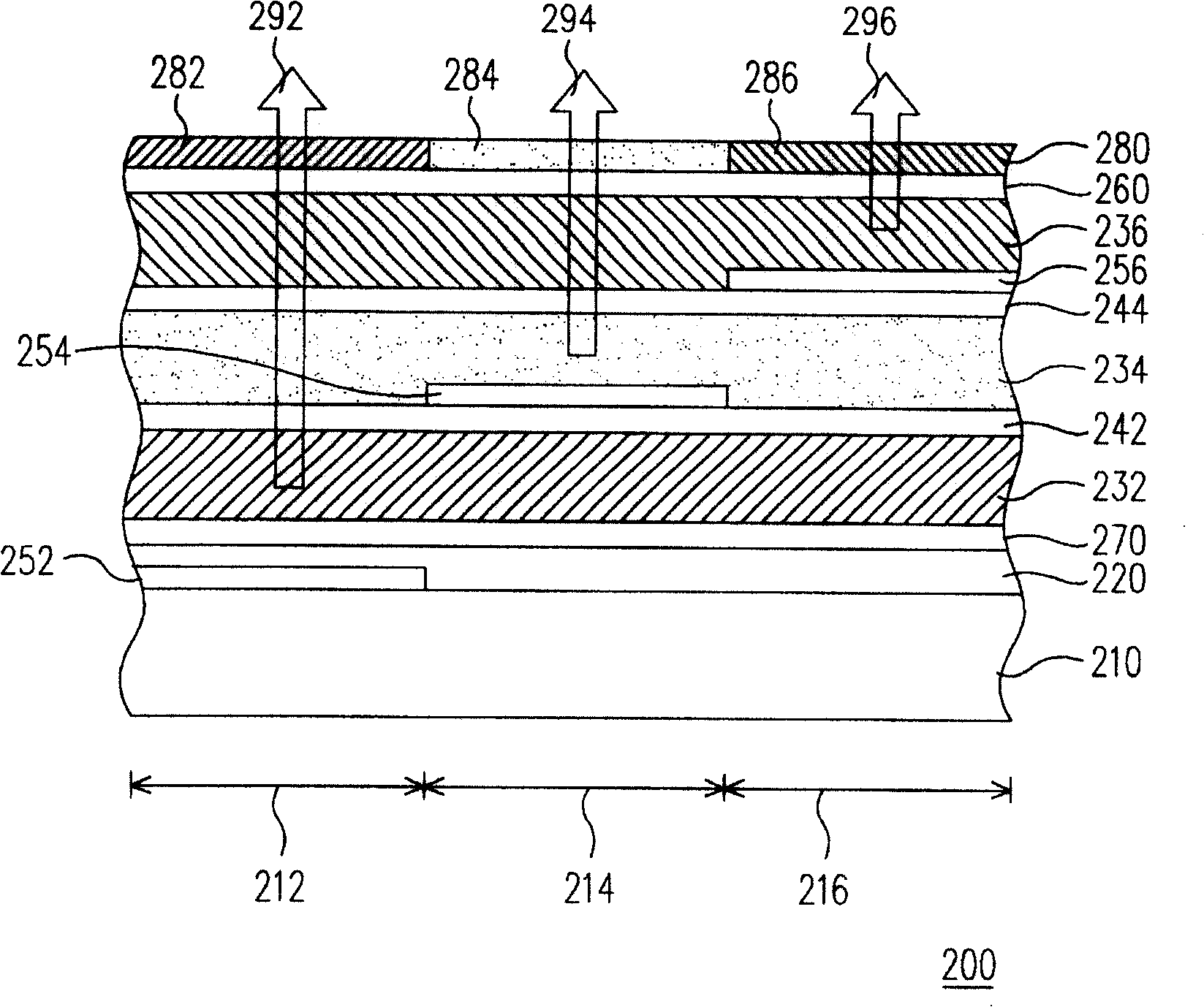

[0064] figure 2 It is a schematic structural view of a stacked organic electroluminescence element in a preferred embodiment of the present invention. Please refer to figure 2 , the stacked organic electroluminescent element 200 includes a substrate 210, an anode layer 220, a plurality of organic light emitting layers 232, 234, 236, a plurality of carrier generation layers 242, 244, a plurality of reflective layers 252, 254, 256 and Cathode layer 260 . Wherein, the substrate 210 has a first light emitting region 212 , a second light emitting region 214 and a third light emitting region 216 . The anode layer 220 is disposed on the substrate 210 . The organic light emitting layer 232 is disposed on the anode layer 220 . The organic light emitting layer 234 is disposed on the organic light emitting layer 232 . The organic light emitting layer 236 is disposed on the organic light emitting layer 234 . The carrier generation layer 242 is disposed between the organic light em...

no. 2 example

[0078] Figure 6A ~ Figure 6E It is a schematic flowchart of the steps of a method for manufacturing a stacked organic electroluminescent device in a preferred embodiment of the present invention. Please refer to as Figure 6A ~ Figure 6E With the steps shown, the process is a continuous process.

[0079] First, if Figure 6A As shown, a substrate 210 having a first light emitting region 212 , a second light emitting region 214 and a third light emitting region 216 is provided. The substrate 210 is, for example, a plastic substrate or a glass substrate.

[0080] Next, if Figure 6B As shown, a reflective layer 252 is formed on the first light emitting region 212 . The reflective layer 252 is disposed in the first light emitting region 212 and on the substrate 210 . The method of forming the reflective layer 252 is, for example, using the patterned mask 310 in conjunction with the evaporation process 320 to form the reflective layer 252 in the first light emitting region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com