Dacron glass fiber dipped canvas and its preparation method

A glass fiber, dipped canvas technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of poor flexural properties of inorganic glass fibers, and achieve the effects of low price, improved heat resistance and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

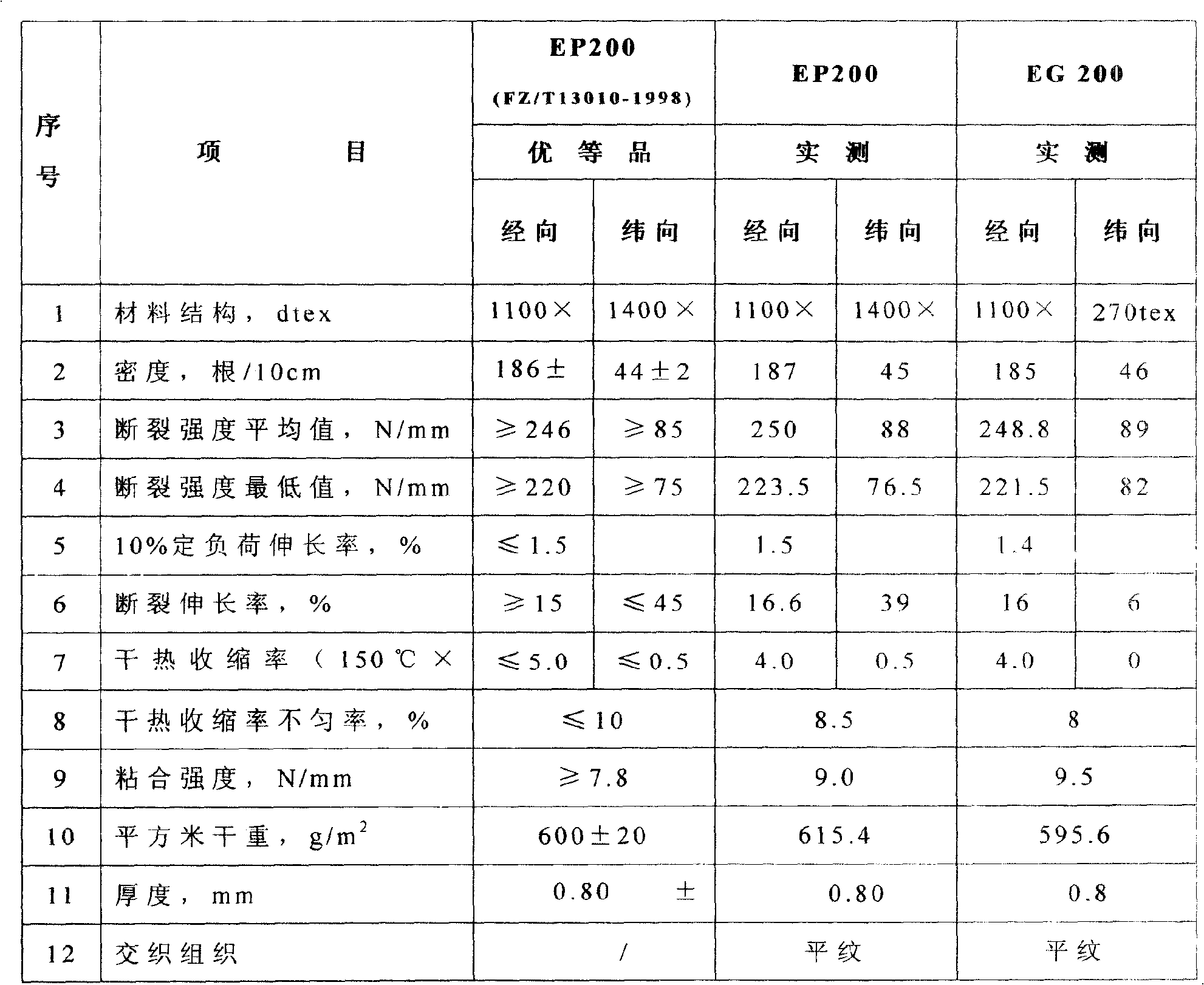

[0052] Below in conjunction with specific example the present invention is described in further detail, the preparation method of a kind of 200 type polyester fiberglass dipped canvas (hereinafter represented by EG200 code name) among the present invention is as follows:

[0053] Preparation of warp and weft materials:

[0054] 1. Warp material: 1100dtex-3300dtex polyester industrial filament can be used. According to the variety requirements of customers, ordinary type, high-strength type, low-shrinkage type and high-modulus low-shrinkage type can be used for twisting production.

[0055] Type EG200 uses 1100dtex high-modulus low-shrinkage polyester industrial filament. According to the strength requirements of type 200, it needs to use 2 strands, that is, 1100dtex×2, and the twist range is 100±15 twists / m;

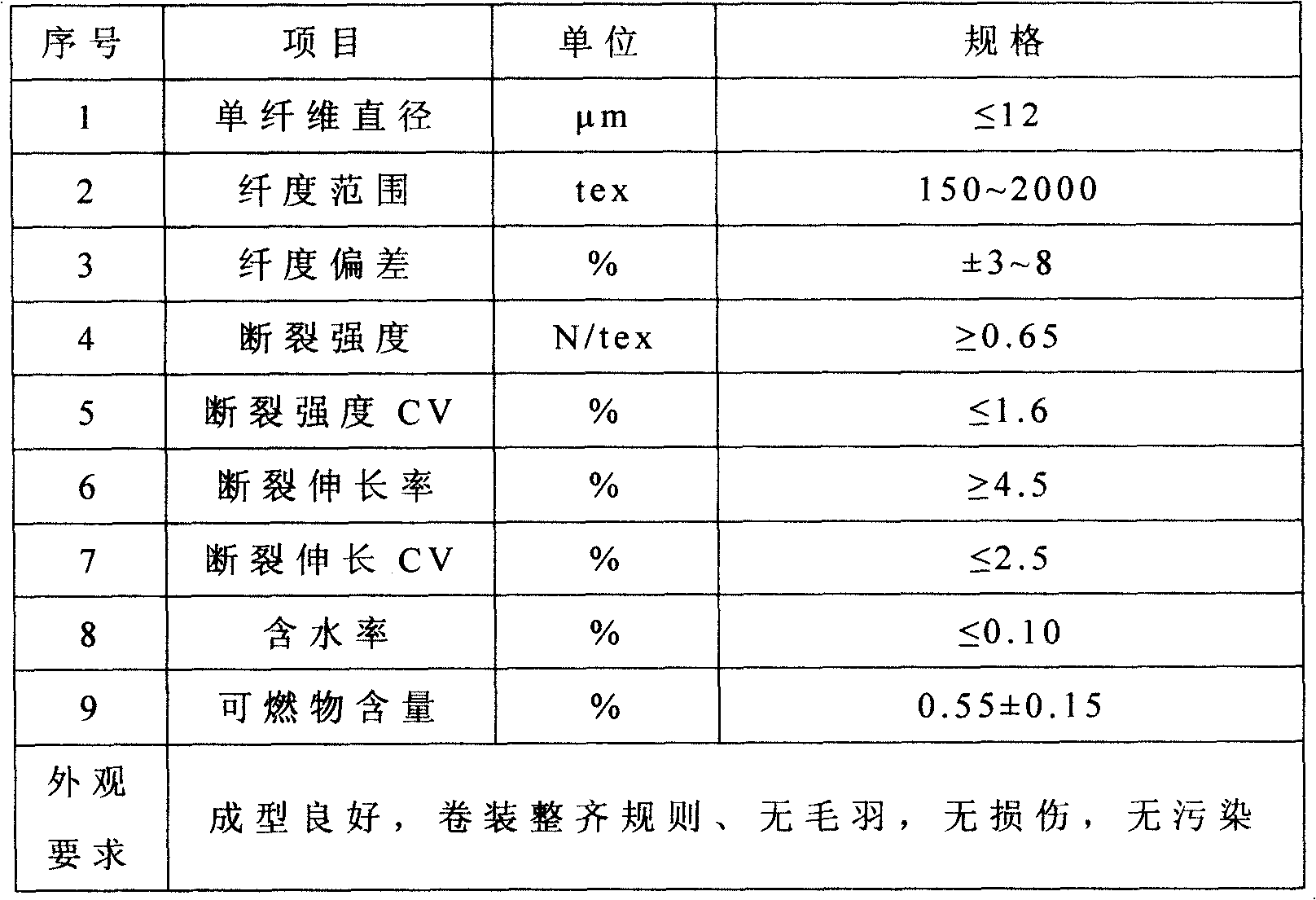

[0056] 2. Weft material: 150tex-2000tex modified glass fiber filaments. When spinning glass fiber, the following requirements are put forward. It is glass fiber of alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com