Concentration method of graduate freezing interface

A progressive freezing and interface technology, which is applied in the fields of climate change adaptation, solution crystallization, food science, etc., can solve the problems of non-commercial application, difficulty in large-scale application, concentration speed limitation and other problems of interface progressive freezing concentration method, and achieve high-efficiency cooling capacity Recycling, easy automatic control, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

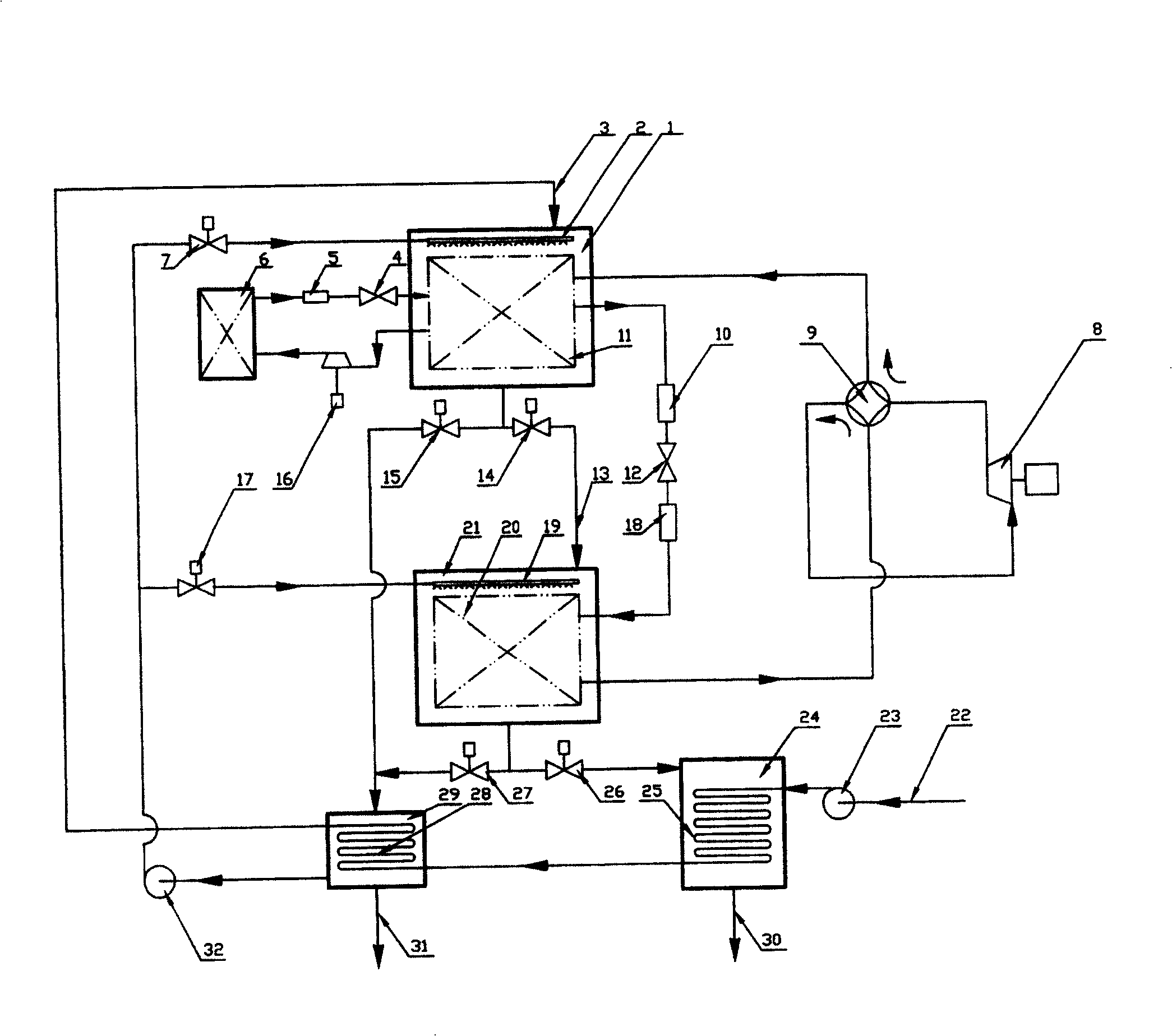

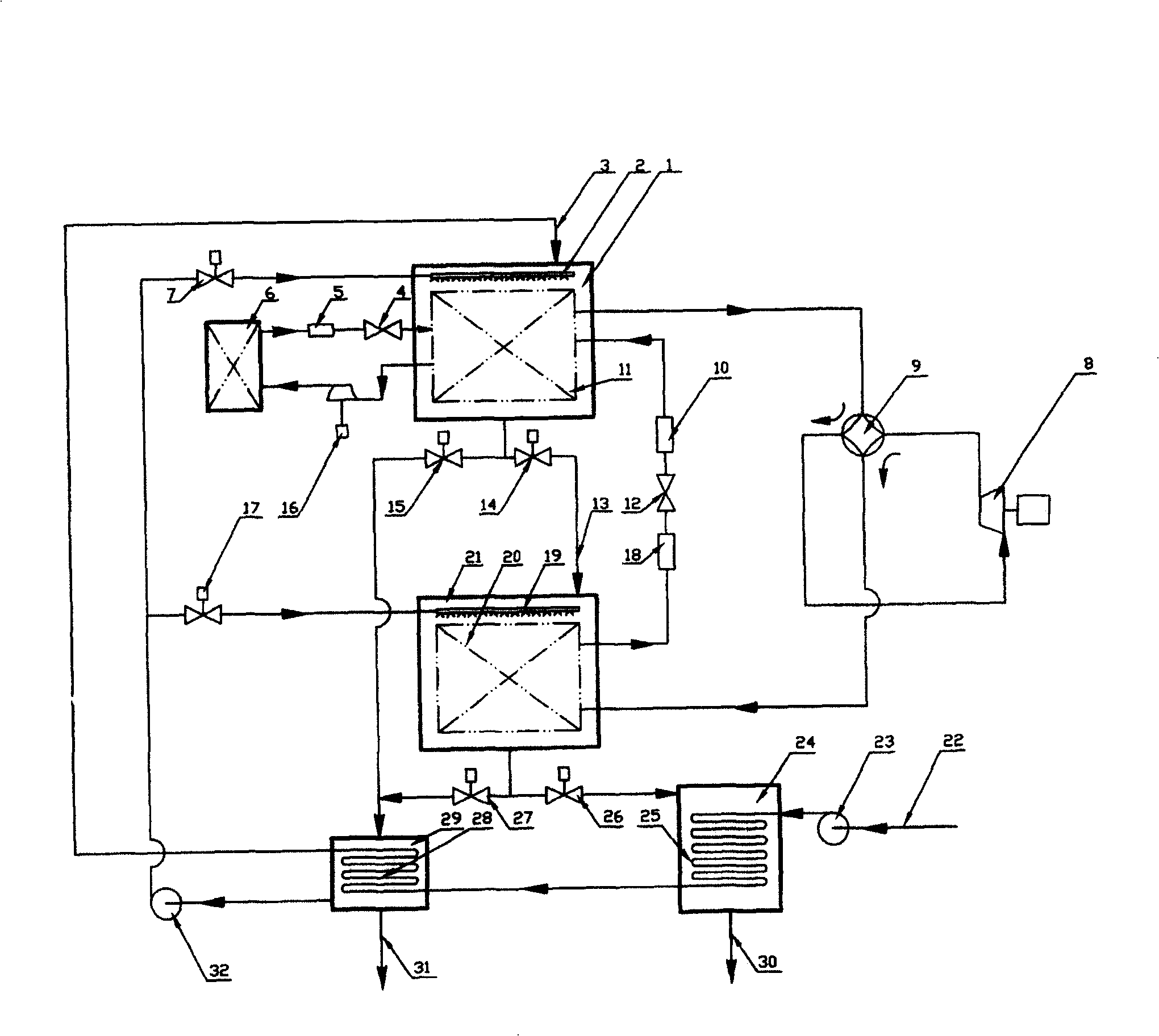

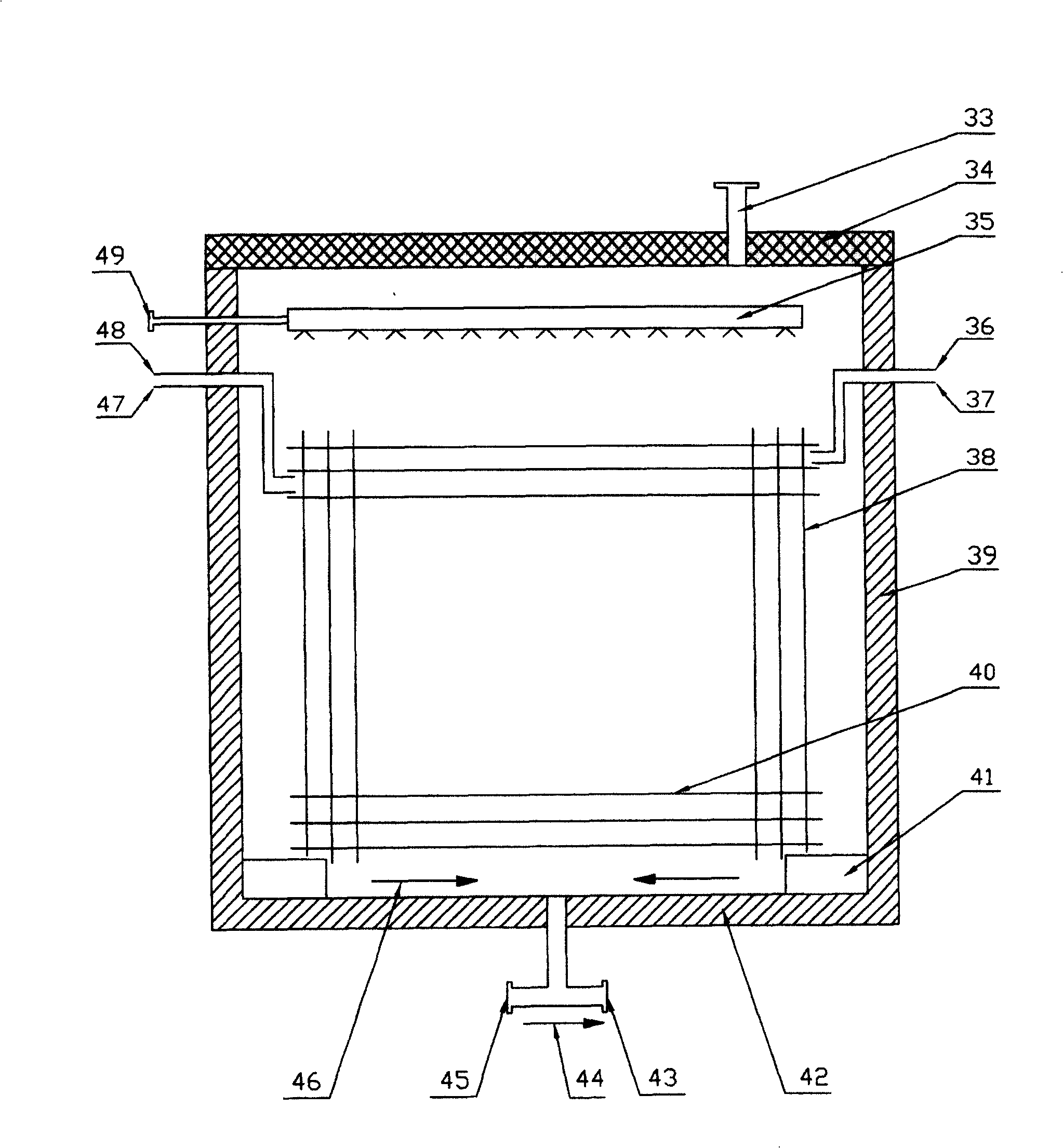

[0025] Embodiment 1: A kind of equipment device that realizes the method of the present invention, its main components include the heat exchanger 11 in the high-level freezing water tank 1, the four-way valve 9, the compressor 8, the heat exchanger in the low-level freezing water tank 21 20. The heat pump cycle subsystem composed of dry filters 10, 18, throttling expansion valve 12 and connecting pipes; consisting of heat exchanger 11, compressor 16, condenser 6, and dry filter 5 in the high-level freezing water tank 1 , throttling expansion valve 4, etc.; the auxiliary refrigeration subsystem composed of feed water solution pump 23, feed water solution cooler 25, 28 and related connecting pipes; feed water solution subsystem composed of high and low freezing water tanks Concentrated solution delivery and discharge subsystem composed of solution discharge valves 14, 26, concentrated solution water tank 24 and related connecting pipelines; melted water discharge valves 15, 27 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com