Laser welding method for sealing hollow thin case aluminum alloy piston body

A technology of laser welding and piston body, which is applied in the direction of laser welding equipment, welding equipment, welding medium, etc., can solve the problems of over-burning of aluminum materials, high thermal conductivity, low work efficiency, etc., and achieve the goal of reducing welding scrap rate and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

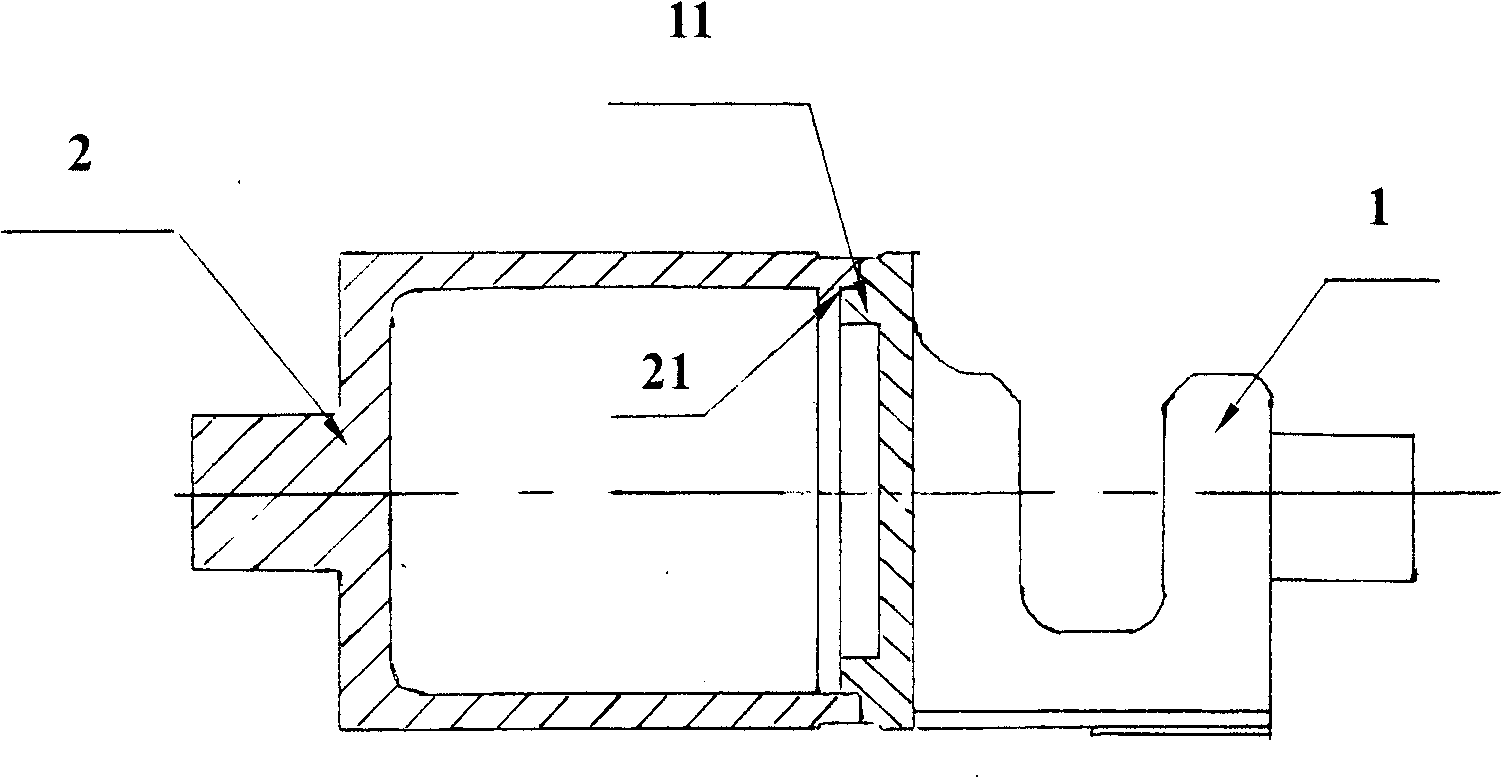

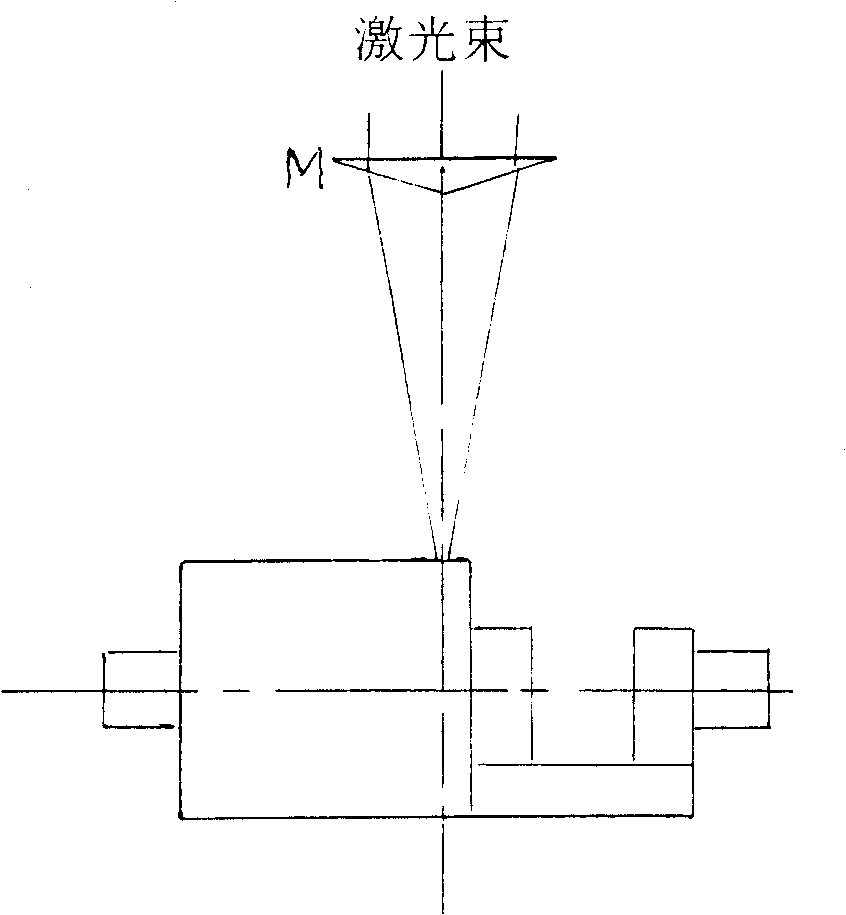

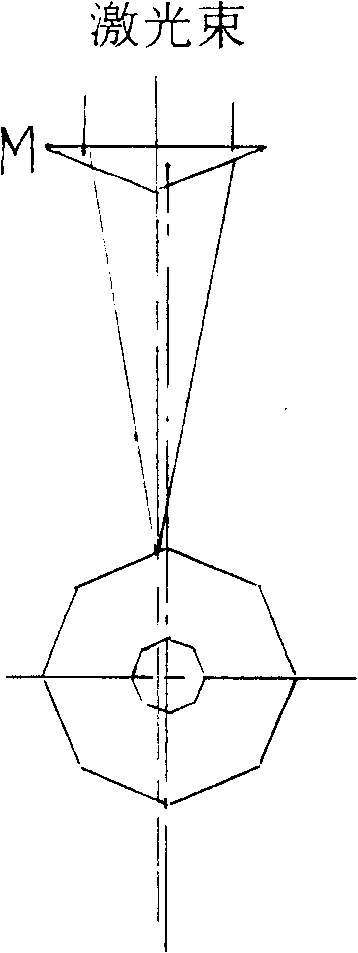

[0026] The purpose of using a hollow piston is to reduce the inertia of the piston. Therefore, the wall of the piston should be as thin as possible under the guarantee of strength. However, if the wall is too thin, the welding strength will be affected, and the weld seam will be easily broken. Therefore require the opening place wall of hollow cylindrical shell 2 to put thick, see figure 2 , there is a section at the opening of the shell, and the thickness of the wall depends on the tensile strength of the laser weld penetration. A protruding step of the piston cover 1 should have an interference fit with the opening aperture (22) of the housing, and the piston cover 1 is press-fitted into the hollow cylindrical housing 2 by pressure, so that the hollow cylindrical housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com