Uniterrupted power gear box

A gear transmission and power technology, which is applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of increased power loss, intermittent power transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

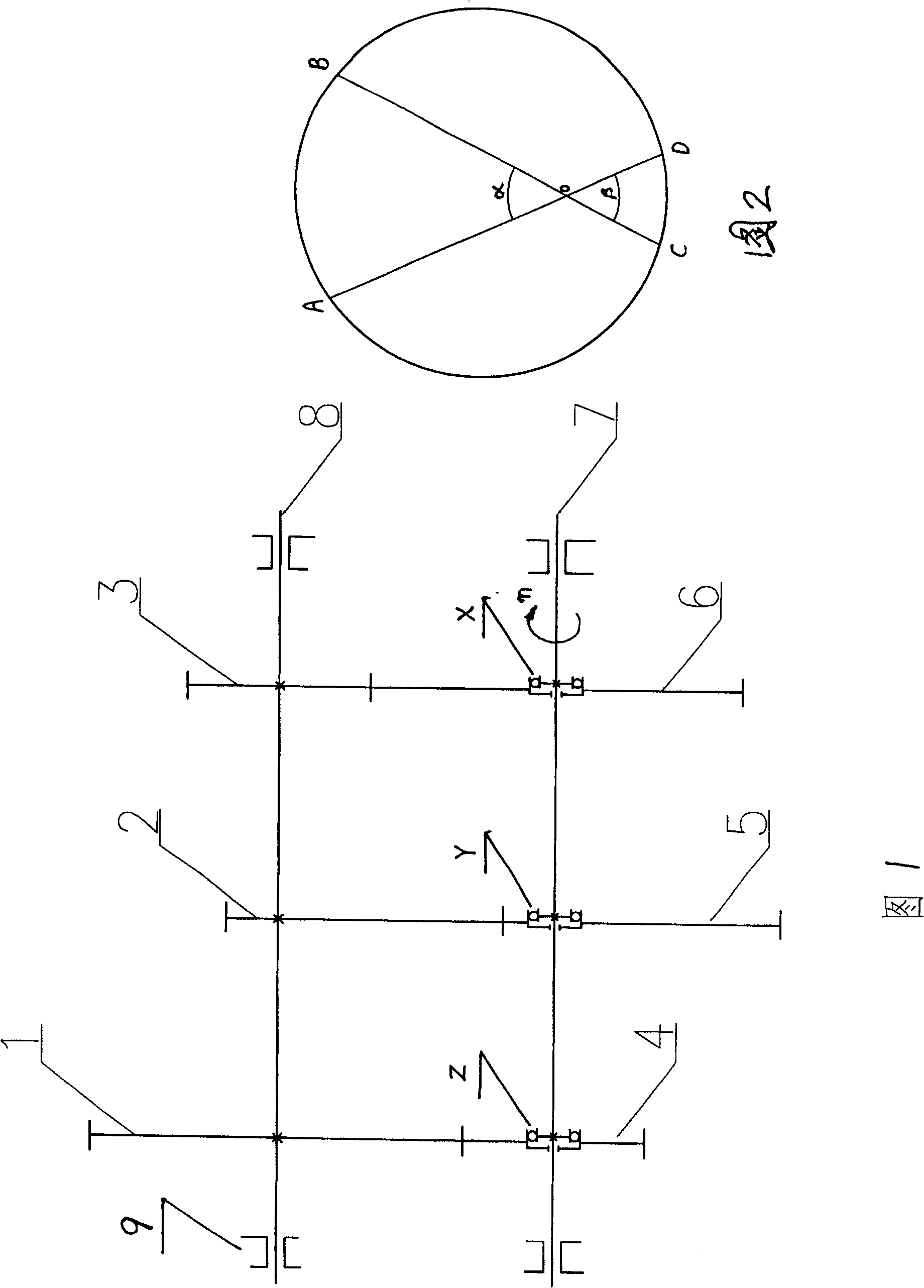

[0020] Embodiment one, a kind of large-scale gear transmission (seeing Fig. 1) of two gears uninterrupted power, two rotating shafts 7,8 that the bearing 9 of base, base are arranged, power is transmitted to rotating shaft 8 from rotating shaft 7. Two opposite rotating shafts 7,8 have circular gears 1,3,4,6 and have constituted a two-speed circular gear mechanism. Rotating shaft 7,8 also has eccentric gear 2,5 and has formed eccentric gear mechanism (seeing figure 2). The eccentric gear mechanisms of these two-speed circular gear mechanisms that are arranged in parallel and output with the steering and a transition gear are all gear mechanisms that are constantly meshed. The driving gears 4, 5, 6 in the two-speed circular gear mechanism and the eccentric gear mechanism are connected with the rotating shaft 7 through the one-way overrunning clutch X, Y, Z, and the driven gears 1, 2, 3 are fixedly connected with the rotating shaft 8. The n-direction speed of the rotating shaft ...

Embodiment 2

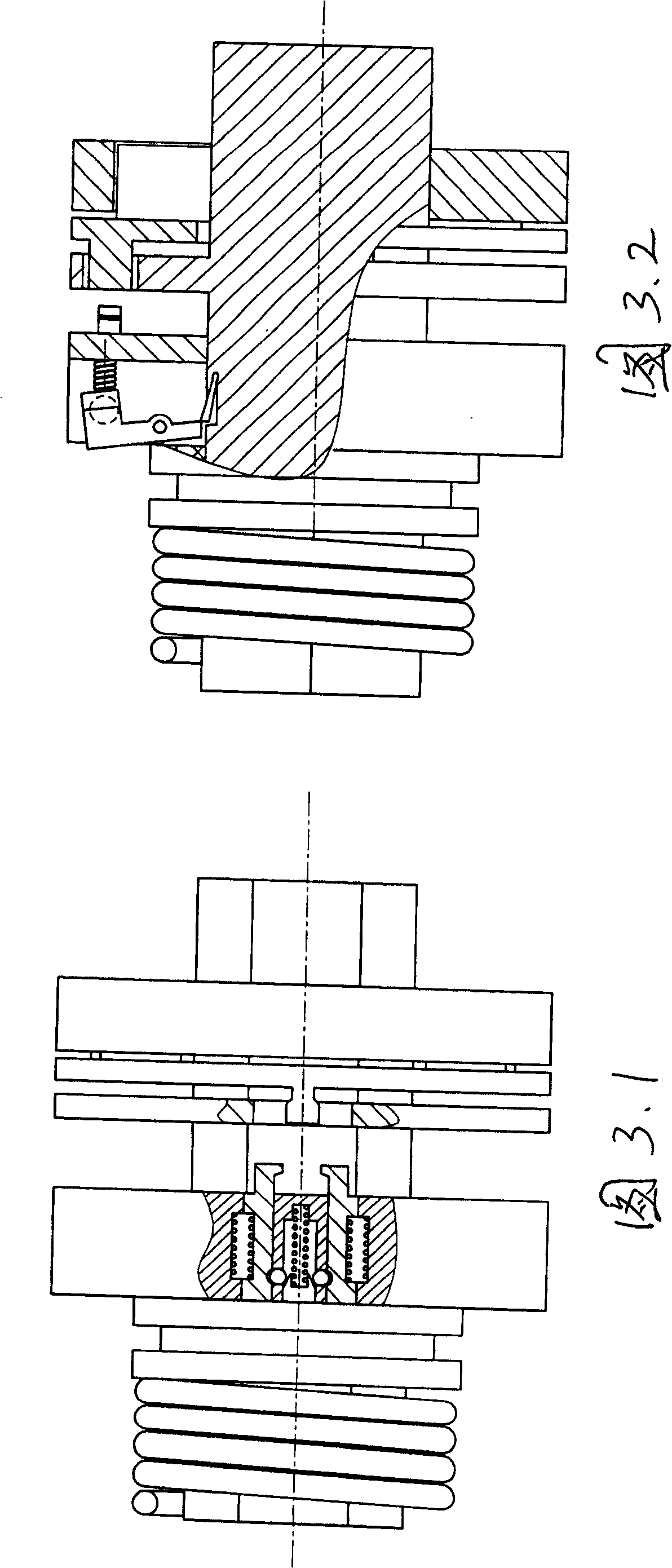

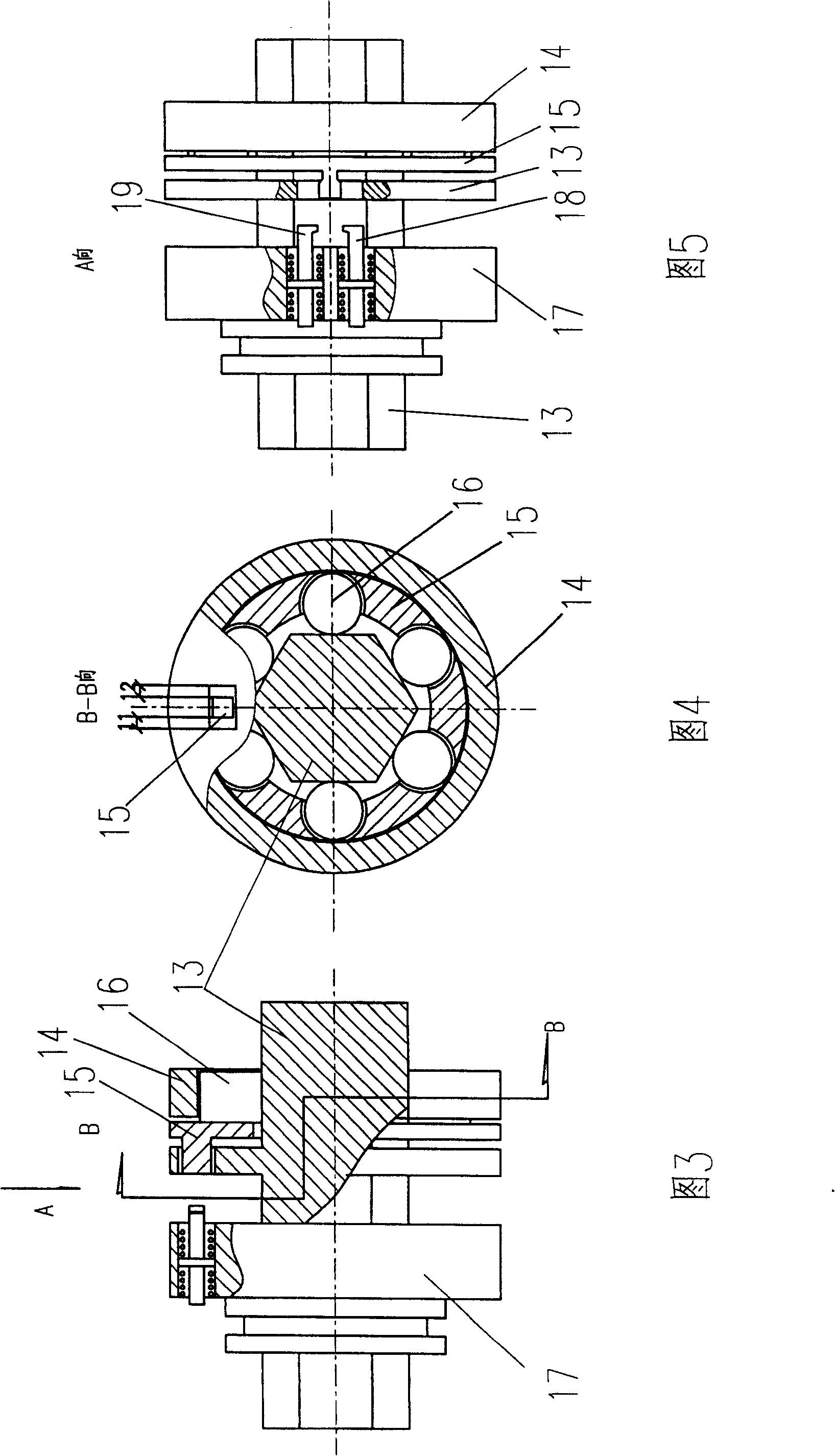

[0021] Embodiment two, a gear transmission (seeing Fig. 1, 2, 3, 4, 5) of two gears uninterrupted power, has two shafts 7,8 that the bearing of gear case, gear case is provided with, shaft 7, Shaft 8 is the input shaft and the output shaft respectively. Shafts 7 and 8 are provided with mutually meshing circular gears 1, 3, 4, 6 and eccentric gears 2, 5, forming a gear mechanism for power transmission with steering output. In the two-stage circular gear mechanism formed by the relatively rotating shafts 7 and 8 and the eccentric gear mechanism corresponding to the transition gear in parallel, each gear mechanism has a gear 4, 5, 6 and the shaft 7 through a roller type two-way The overrunning clutch X, Y, Z is connected. The overrunning clutch of gear 4,5,6 is made of the shell 14 that is fixedly connected with gear, the star wheel 13 that is connected with axle 7, the roller 16 that is arranged between star wheel and shell and constitutes. There is also a claw 15 between the ...

Embodiment 3

[0025]Embodiment three, a kind of gear transmission (seeing Fig. 36, also referring to Fig. 8) of four gears uninterrupted power, has gear case, the bearing of gear case is equipped with input shaft 87 and output shaft 88, these two opposite The shaft that rotates and transmits the power is provided with four forward-rotating circular gear mechanisms, and a forward-rotating oval gear mechanism is also juxtaposed in the middle of every adjacent two-grade circular gear mechanism. The bearings, input shaft, output shaft, four pairs of circular gears, and three pairs of non-circular gears of the gear box respectively constitute a circular gear mechanism with four gears and a non-circular gear mechanism with three transition gears, and together with the gear box A four-stage transmission is formed. The gear transmission transmits power in one direction, and the power is transmitted from the shaft 87 to the shaft 88 . From the first gear circular gear mechanism to the fourth gear c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com