Compression ignition internal combustion engine

A technology of internal combustion engines and engines, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as insufficient satisfaction, deterioration of black smoke problems, and difficulty in improving black smoke problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

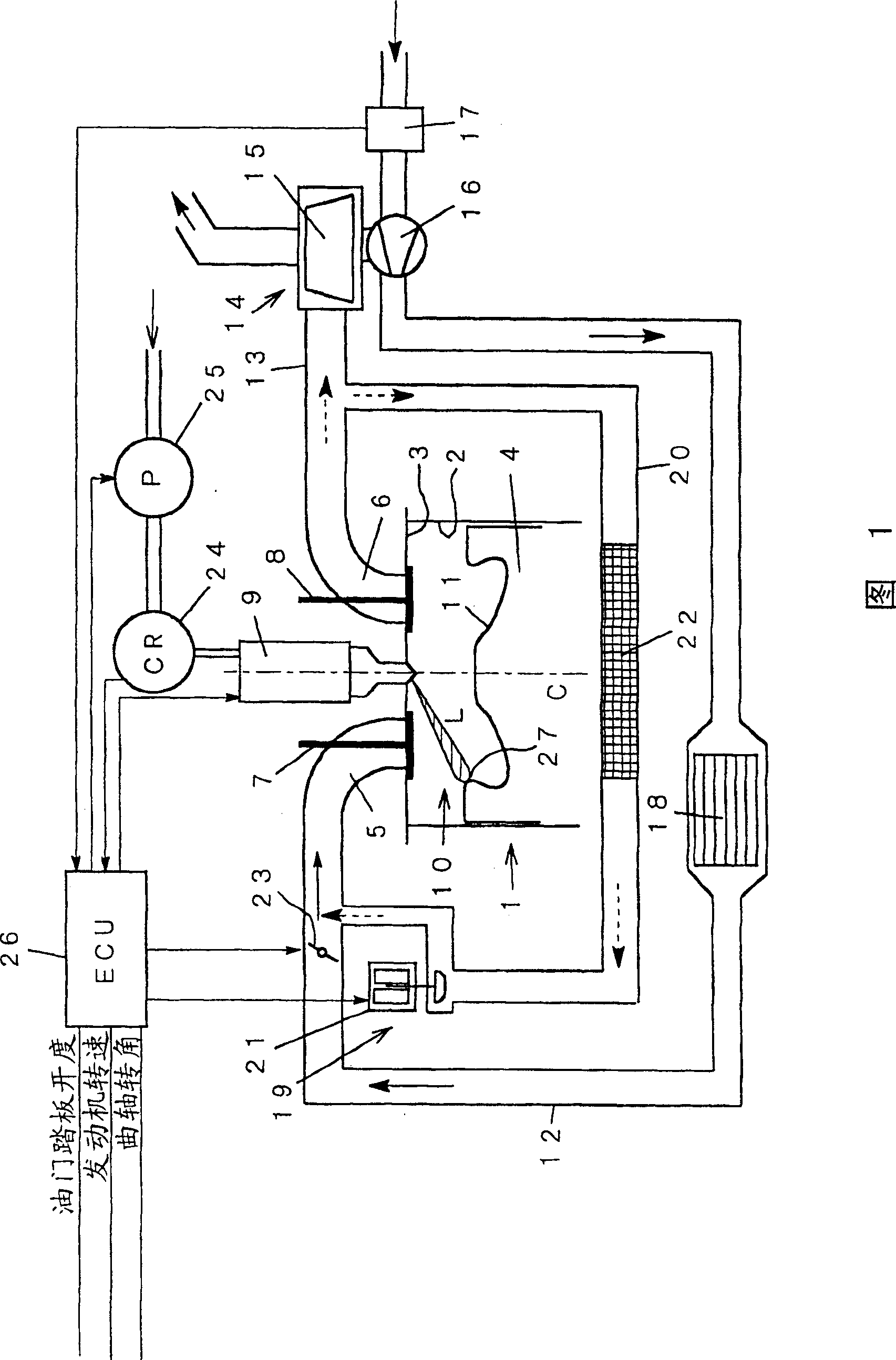

[0038] FIG. 1 depicts a compression ignition internal combustion engine related to this embodiment. The so-called compression ignition internal combustion engine here refers to such an engine in which the fuel injected into the combustion chamber is spontaneously ignited in the cylinder by compression of the cylinder, and the above compression ignition internal combustion engine is typically a diesel engine. Especially in the case of this embodiment, the engine is a common rail diesel engine including a common rail fuel injection device. For convenience, a single cylinder is shown in the schematic, but multi-cylinder machines are of course also possible. Such an engine is mounted on a vehicle.

[0039] 1 is the engine body, which includes cylinder 2, cylinder head 3, piston 4, intake port 5, exhaust port 6, intake valve 7, exhaust valve 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com