Fan convex ring thin wall metal pipe, its processing method and special equipment

A technology of metal pipes and convex rings, which is applied in the direction of mechanical equipment, pipes/pipe joints/fittings, sealing surfaces, etc., can solve the problem that the convex rings of pipe fittings cannot be inserted into the connecting pipe fittings, thin-walled pipes and convex rings are not round, and the pipe pulls Poor pull-out strength and other problems, to achieve the effect of being conducive to assembly and use, good sealing, and high pull-out strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

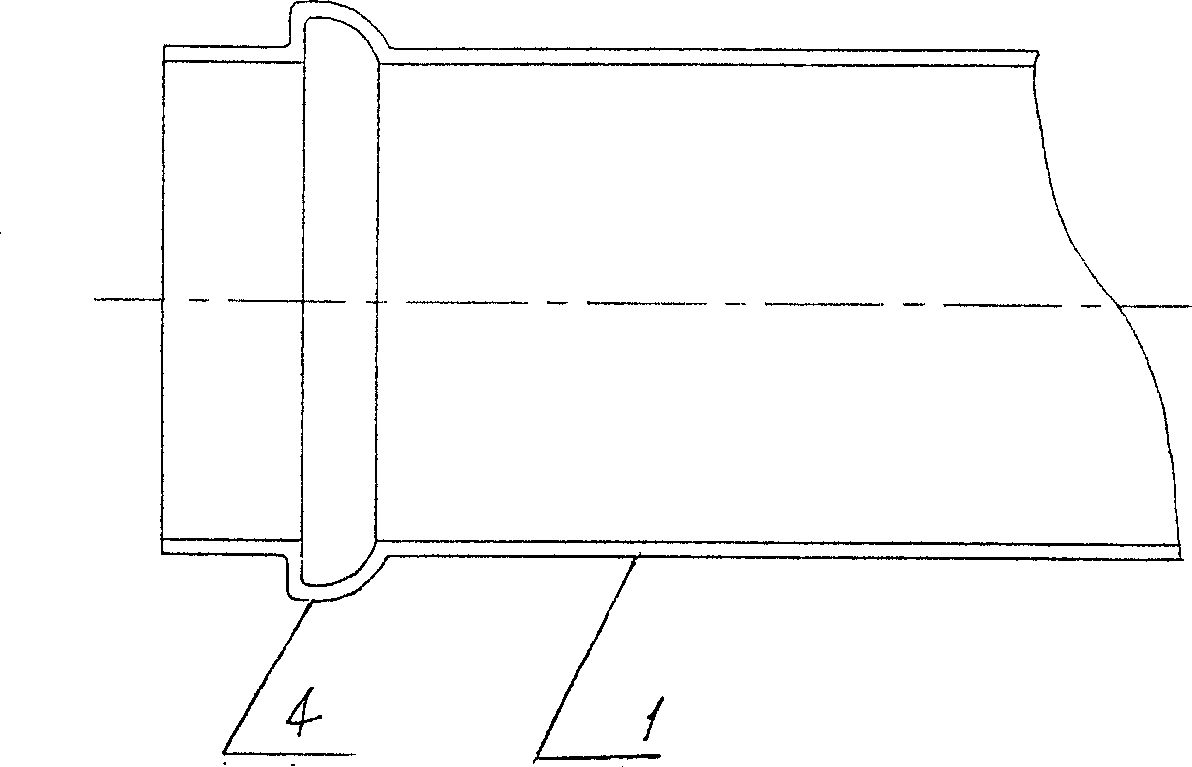

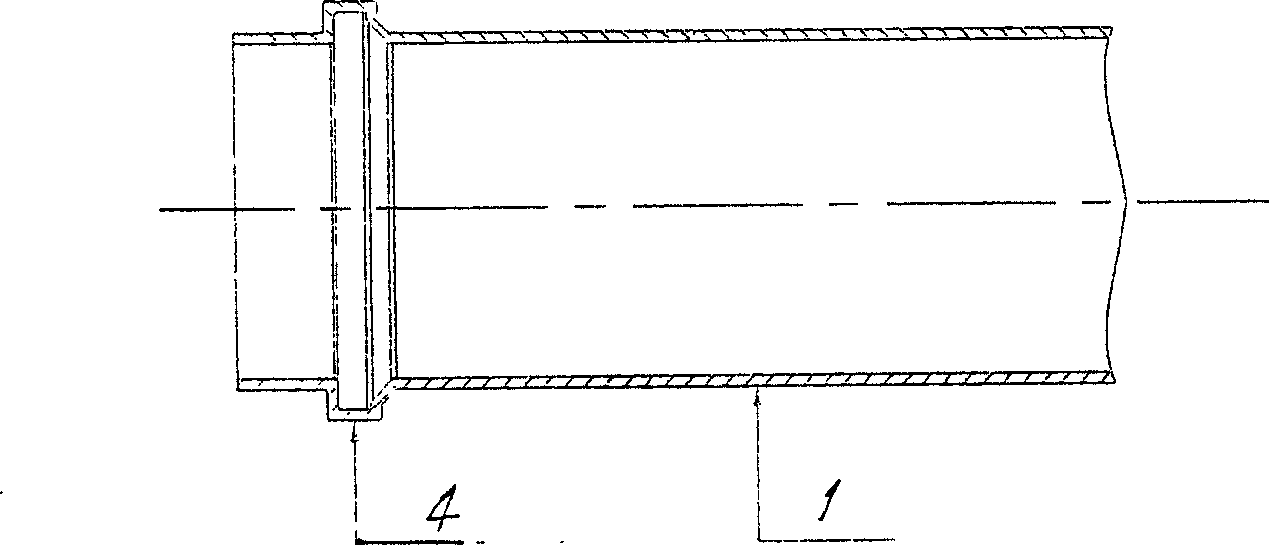

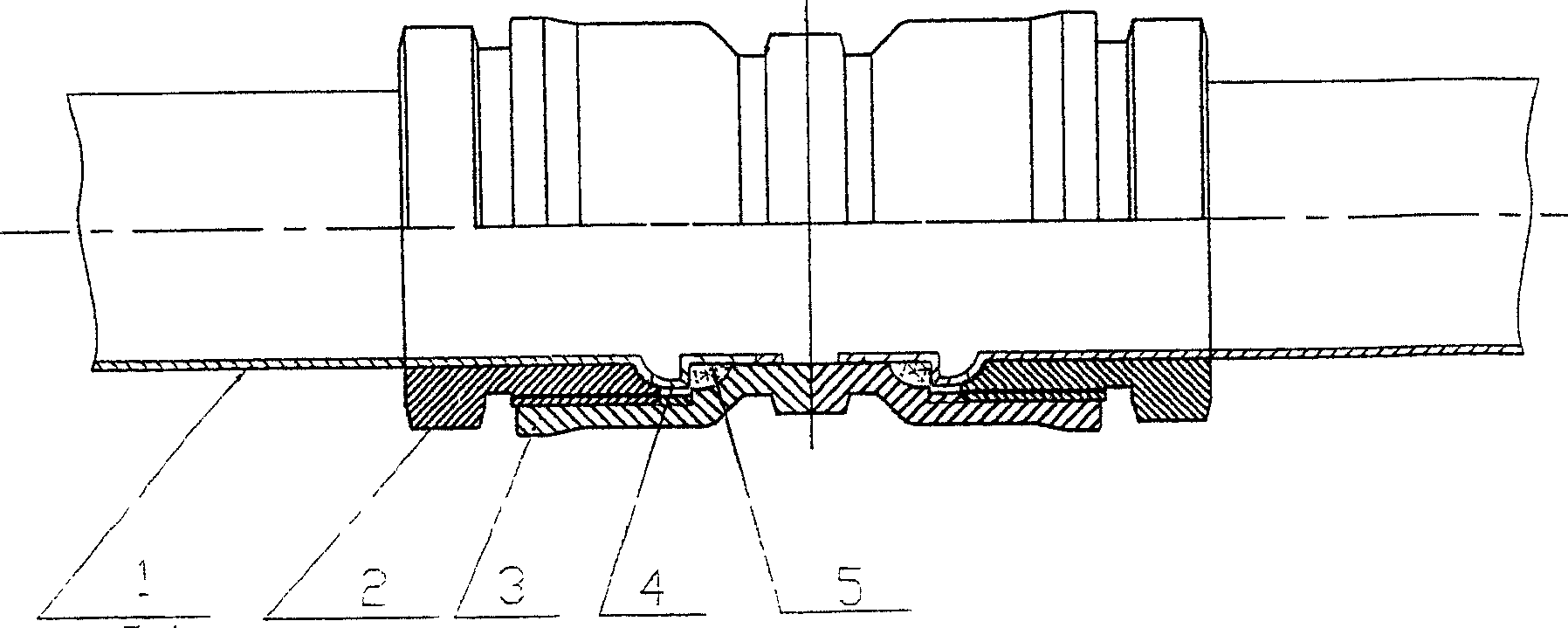

[0015] According to the accompanying drawings, when two fan-shaped convex ring thin-walled metal pipes 1 are connected, the outer periphery of the pipe body between the two convex rings 4 is surrounded by a connecting pipe fitting 3 that plays a connecting role, and the length of the connecting pipe fitting 3 is greater than that between the two convex rings 4. Distance, the inner wall of the connecting pipe fitting 3 is provided with threads, and the two ends are connected with the connecting pipe fitting 3 with compression bolts 2 respectively. The inner wall of the sealing ring 5 is provided with arc grooves correspondingly.

[0016] The core roller 14 of the inner mold is a convex die, and the outer diameter of the roller 14 of the inner mold must be smaller than the inner diameter of the processed pipe fitting. The hollow roller 11 of the outer mold is used as a die, and the inner diameter of the hollow roller 11 of the outer mold must be larger than the convex ring of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com