Bactericidal PVC gloves and a production process thereof

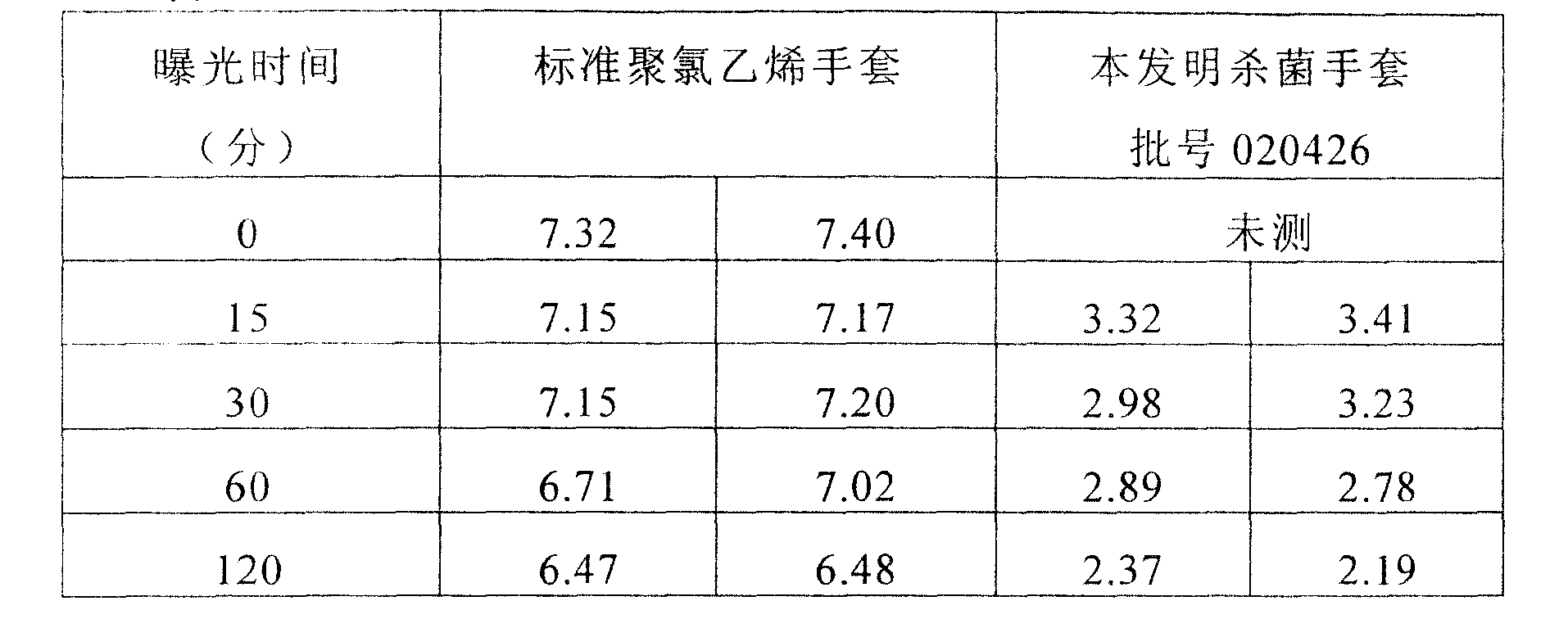

A production process and glove technology, applied in the directions of biocides, plant growth regulators, animal repellents, etc., can solve the problems of expanding the scope of infection, worrying about aggravation, inability to kill germs, etc., and achieve the effect of obvious bactericidal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

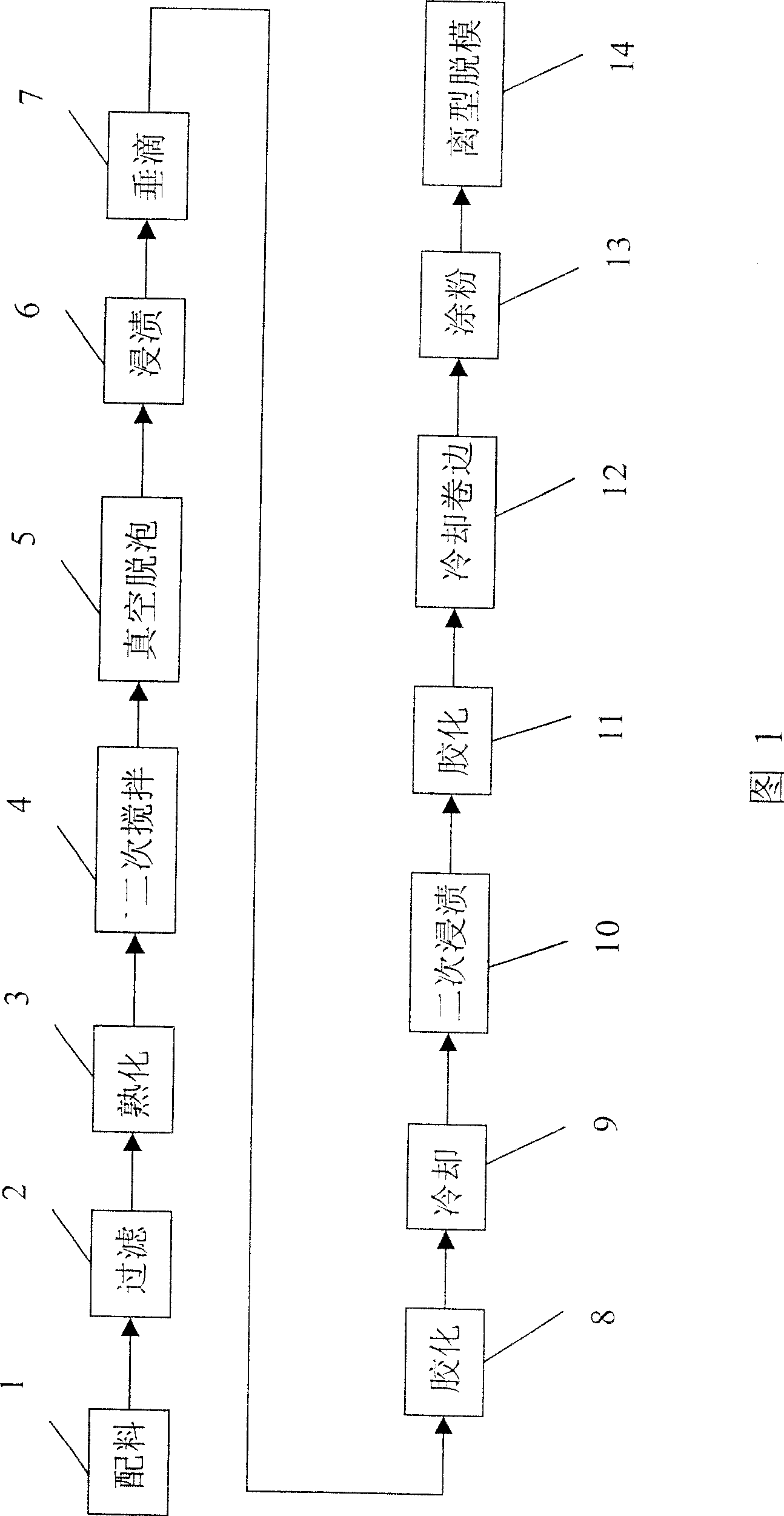

[0034] Example 1: 4020kg of polyvinyl chloride, 3620kg of plasticizer, 970kg of butyrate, 80kg of stabilizer, 435kg of bactericidal powder, 26kg of dispersant, and 1.74kg of surfactant.

example 2

[0035] Example 2: polyvinyl chloride 5000kg, plasticizer 4250kg, butyrate 1000kg, stabilizer 100kg, bactericidal powder 569.25kg, dispersant 31.05kg, surfactant 3.62kg.

[0036] After weighing according to the weight of the above-mentioned raw materials, put the plasticizer, butyrate and stabilizer into the mixing tank, stir quickly for 8-10 minutes, then add PVC powder, and use the hydraulic pump of the mixer to lift up and down 4 times , let the PVC powder completely dispersed, and then timing and stirring for 2 hours.

[0037] After the stirring is completed, filter with a strainer (120 mesh) to complete the batching.

[0038] The prepared raw materials are pumped into the aging barrel by a gear pump for more than 2 days of aging.

[0039] After more than 2 days of aging, use a gear pump to pump to the second mixer for the second stirring, and control the viscosity at 250±50ops. Viscosity adjustment Add viscosity reducer in an appropriate amount, after stirring for 40 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com