Built-in magnet pole dividing permanent-magnet single-phase generator

A technology of single-phase generator and magnetic pole division, which is applied to the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., to achieve the effects of short axial length, high efficiency and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

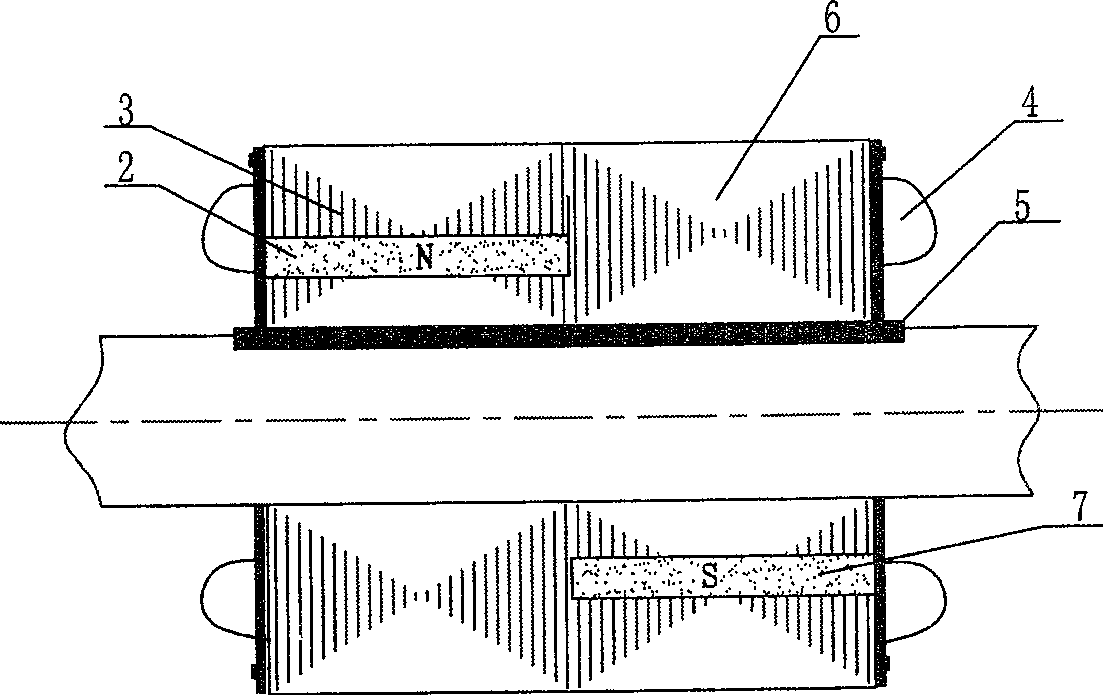

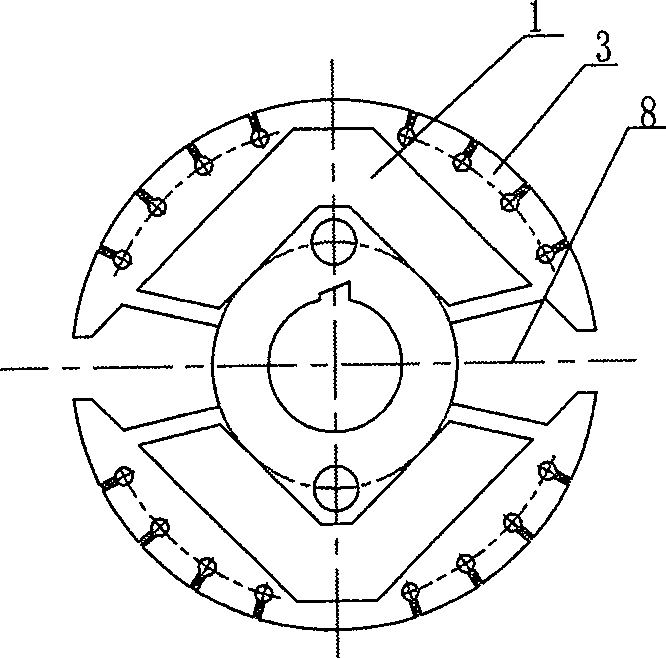

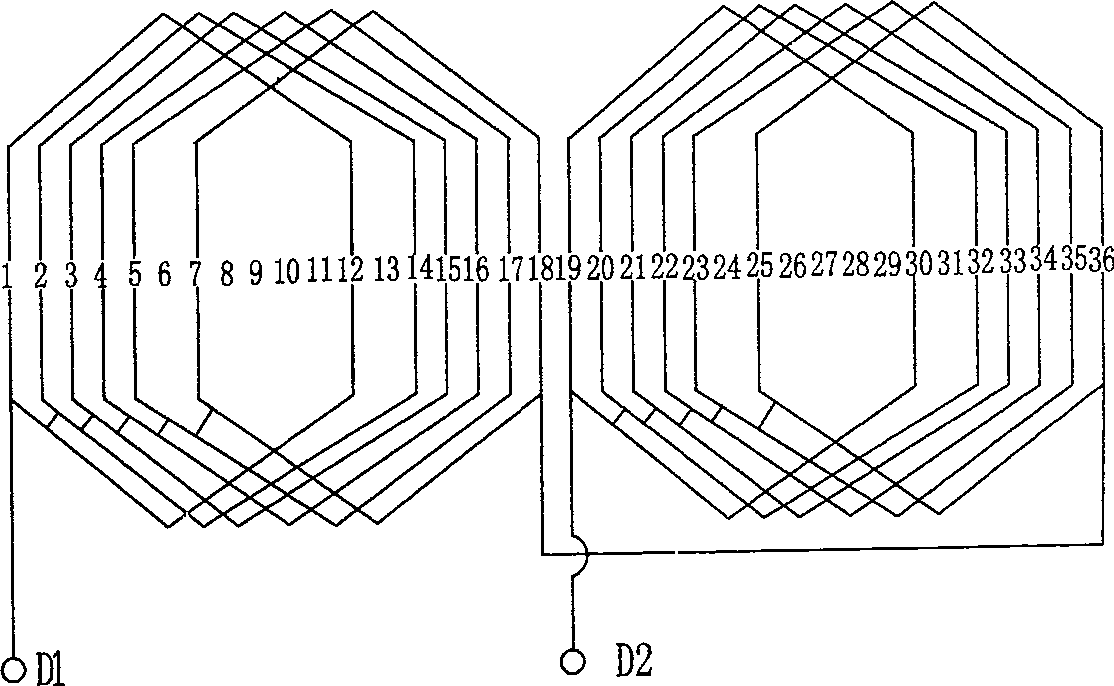

[0009] Such as figure 1 , figure 2 As shown, the utility model includes a stator iron core and a rotor iron core, and is characterized in that: the stator punching sheet and the rotor punching sheet all use one punching sheet, the rotor punching sheet is a two-pole motor rotor punching sheet 3, and the rotor punching sheet 3 two A herringbone groove 1 is opened in the first magnetic pole shoe, and a permanent magnet and a magnetizer are placed in the groove. The permanent magnet plays the role of dividing the magnetic field. There are also two trapezoidal slots 8 in the rotor sheet, and the rotor excitation winding 4 is wound in the slot, and the rotor excitation winding 4 is connected with a rectifier diode to form a self-rectification electric excitation. The rotor core is evenly divided into two sections, the N pole permanent magnet 2 is placed on the left section, and the N pole permanent magnet faces upwards, and the S pole permanent magnet 7 is placed on the right sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com