Red light organic electroluminescent device

An electroluminescence and device technology, applied in the field of red light organic electroluminescence devices, can solve problems such as no substantial improvement, and achieve the effects of improving electroluminescence performance, high efficiency, and ensuring color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

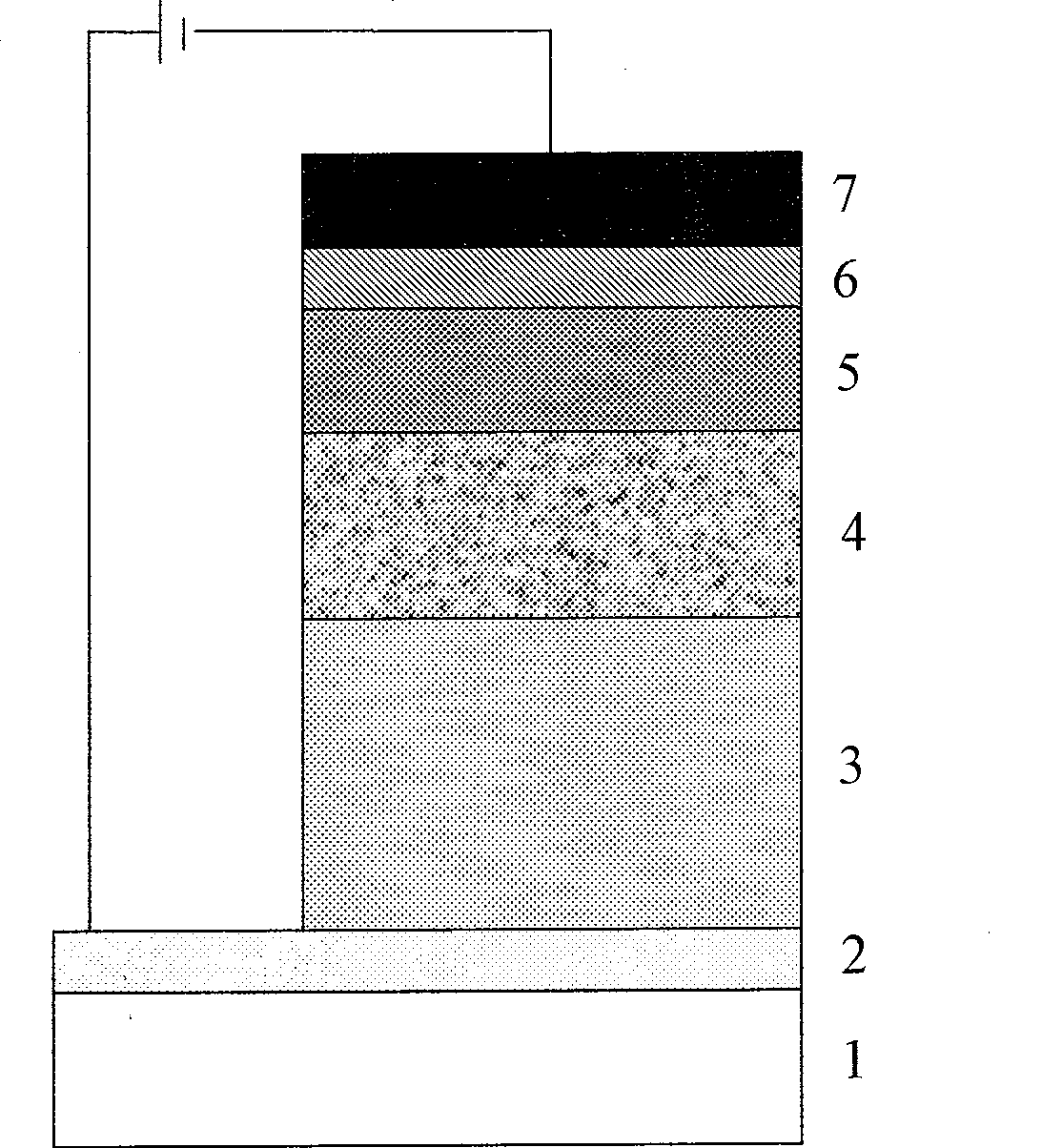

Method used

Image

Examples

Embodiment 1

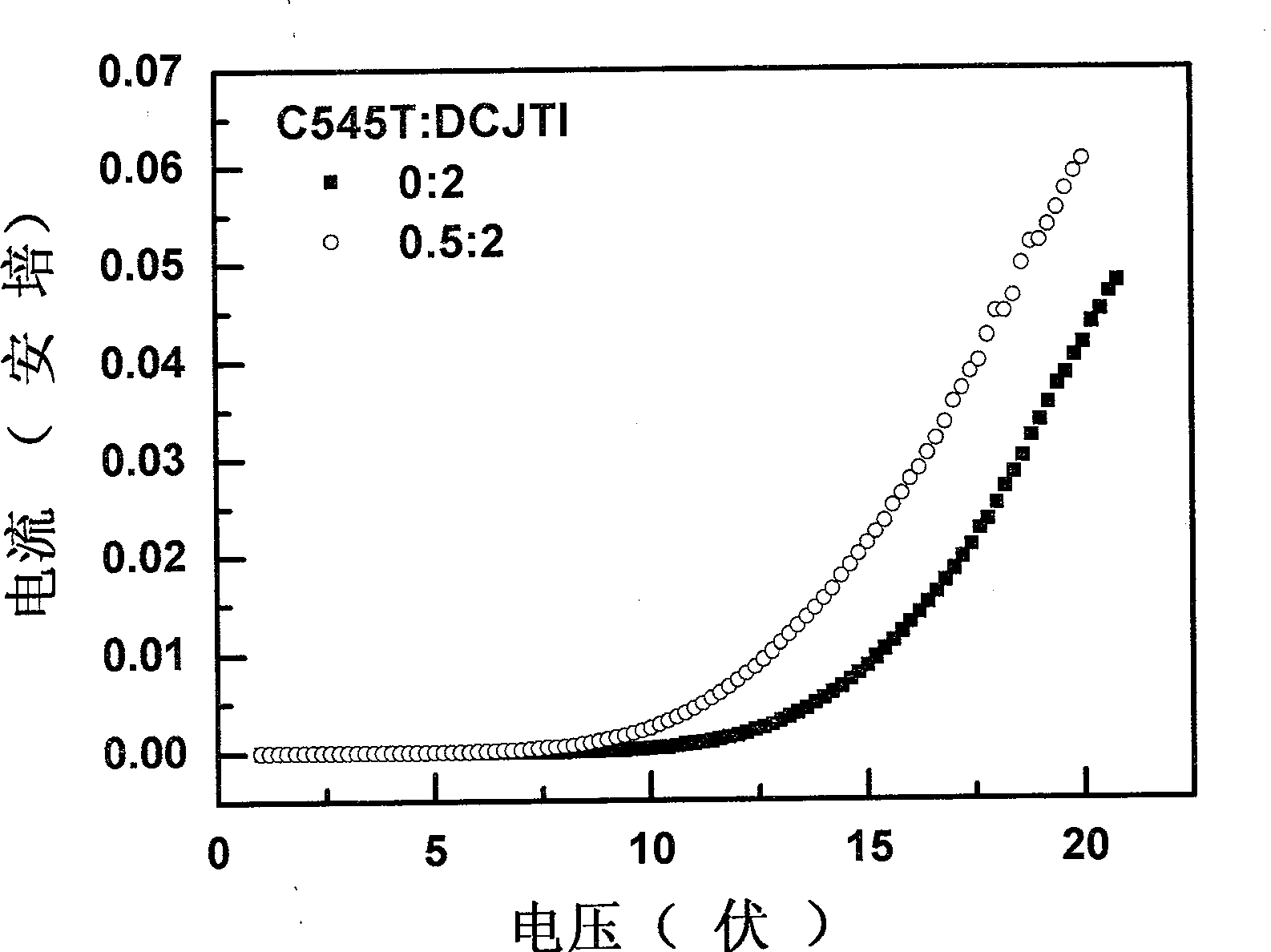

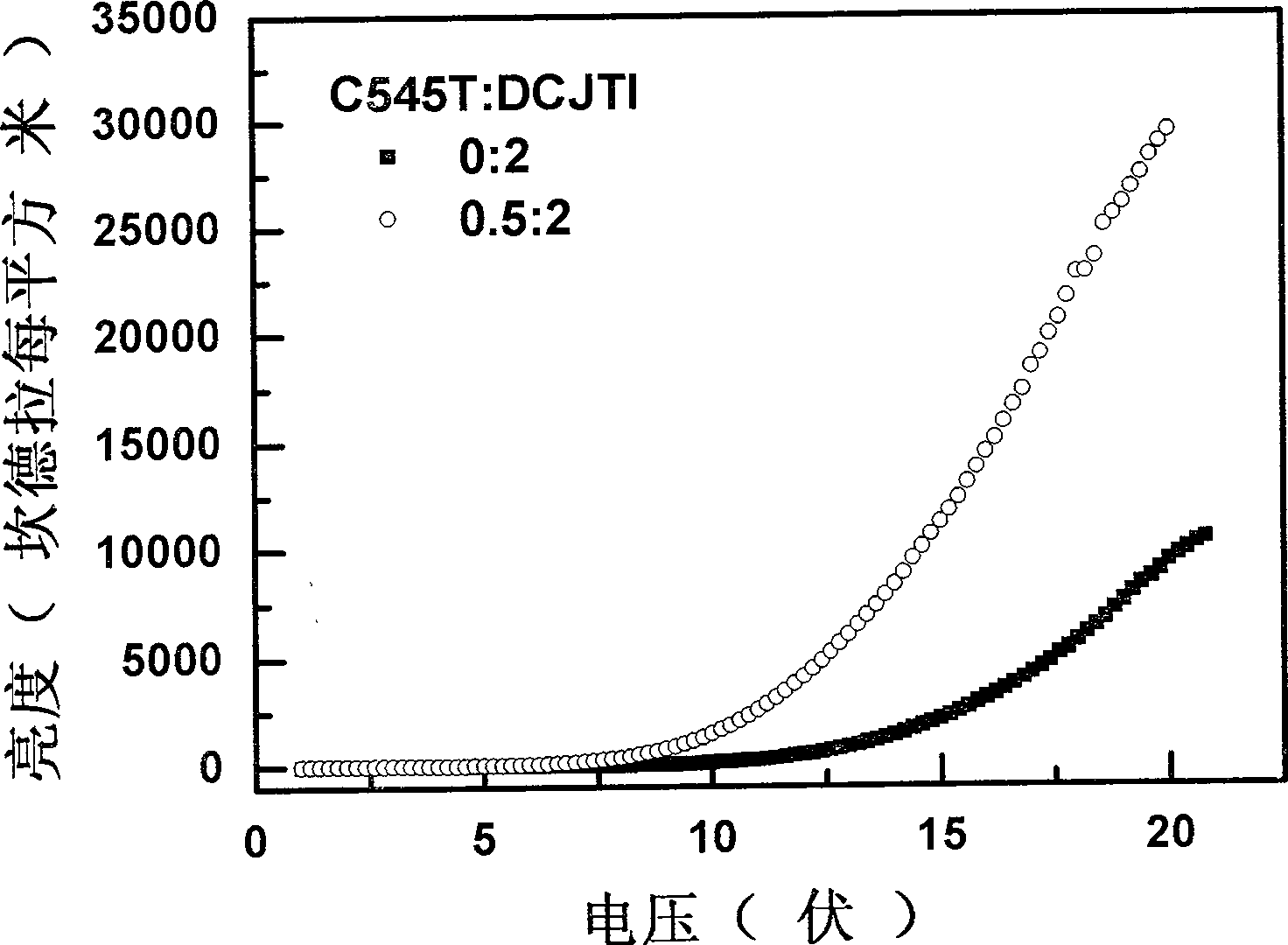

[0034] Doping C545T and DCJTI into Alq 3 As a light-emitting layer, prepared into a structure of ITO / NPB / Alq 3 :C545T: DCJTI / Alq 3 / LiF / Al electroluminescent device. At 10 -4 The organic and metal electrode layers are evaporated under the vacuum of Pa. The evaporation rate of the organic layer is controlled at , LiF evaporation rate control , The metal evaporation rate is controlled at . Alq 3 : C545T: The doping concentration ratio of DCJTI is controlled at 1:0.5%:2%. Among them, the thickness of the NPB layer is 50nm, the doped light-emitting layer is 30nm, and the Alq 3 The layer is 20 nm, the LiF layer is 1 nm, and the Al layer is 100 nm. The resulting device is driven by a DC voltage to obtain DCJTI's red light emission. The maximum power efficiency is 9.4lm / W, the maximum current efficiency is 11.2cd / A, and the maximum brightness can reach 29500cd / m. 2 , The main peak of luminescence is 615nm. Under the same conditions, the maximum power efficiency of the device without C54...

Embodiment 2

[0036] Doping C545T and DCJTI into Alq 3 As a light-emitting layer, prepared into a structure of ITO / NPB / Alq 3 :C545T: DCJTI / Alq 3 / LiF / Al electroluminescent device. At 10 -4 The organic and metal electrode layers are evaporated under the vacuum of Pa. The evaporation rate of the organic layer is controlled at , LiF evaporation rate control , The metal evaporation rate is controlled at . Alq 3 : C545T: The doping concentration ratio of DCJTI is controlled at 1:0.5%:1%. Among them, the thickness of the NPB layer is 50nm, the doped light-emitting layer is 30nm, and the Alq 3 The layer is 20 nm, the LiF layer is 1 nm, and the Al layer is 100 nm. The resulting device is driven by a DC voltage to obtain DCJTI red light, with a maximum power efficiency of 8.91m / W, a maximum current efficiency of 12.6cd / A, and a maximum brightness of 33200cd / m 2 , The main peak of luminescence is 607nm. Under the same conditions, the maximum power efficiency of the device without C545T is only 2.7lm / W...

Embodiment 3

[0038] Doping C545T and DCJTB into Alq 3 As a light-emitting layer, prepared into a structure of ITO / NPB / Alq 3 :C545T: DCJTB / Alq 3 / LiF / Al electroluminescent device. At 10 -4 The organic and metal electrode layers are vapor deposited under the vacuum of Pa’s, and the vapor deposition rate of the organic layer is controlled at , LiF evaporation rate control , The metal evaporation rate is controlled at . Alq 3 The doping concentration ratio of :C545T:DCJTB is controlled at 1:0.5%:0.5%. Among them, the thickness of the NPB layer is 50nm, the doped light-emitting layer is 30nm, and the Alq 3 The layer is 20 nm, the LiF layer is 1 nm, and the Al layer is 100 nm. The resulting device is driven by a DC voltage to obtain DCJTB red light, with a maximum power efficiency of 10.9lm / W, a maximum current efficiency of 11.7cd / A, and a maximum brightness of 23700cd / m 2 , The main peak of luminescence is 612nm. Under the same conditions, the maximum power efficiency of the device without C545...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com