Method for plating ternary alloy on outer conductor of semisteel concentric transmission line

A ternary alloy, coaxial cable technology, applied in liquid chemical plating, superimposed layer plating, metal material coating process and other directions, can solve the problems of outer conductor material failure, affecting appearance quality, easy to be scratched and so on , to improve the ability of environmental corrosion resistance, good appearance quality, not easy to be scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

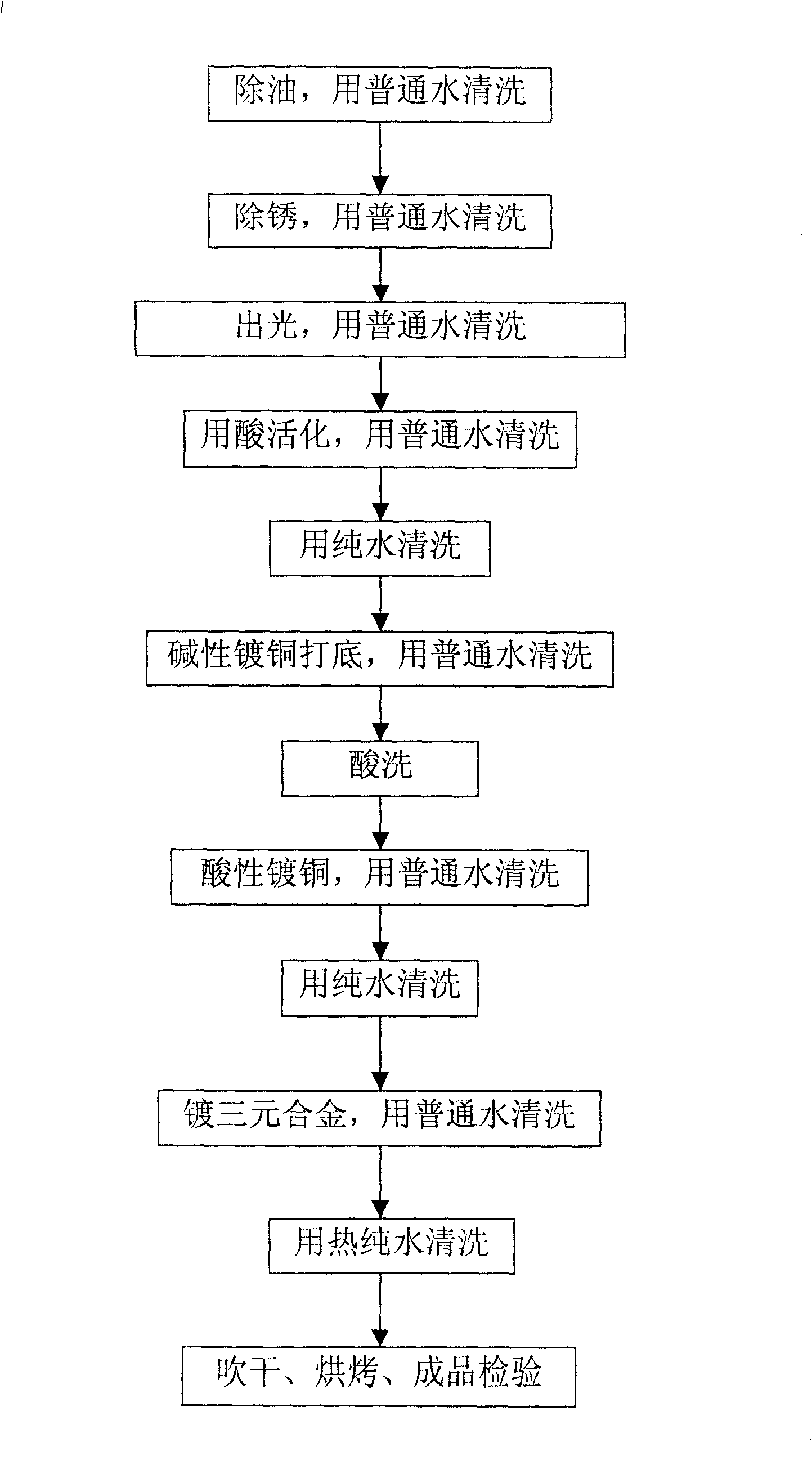

[0032] figure 1 Embodiment 1 of the method for plating a ternary alloy on the outer conductor of a semi-rigid coaxial cable according to the present invention is shown. Such as figure 1 As shown, the method includes the following steps:

[0033] 1. Degrease the outer conductor, and then wash it with ordinary water (such as tap water, the same below), usually twice;

[0034] 2. Carry out pickling and derusting treatment, and then wash with ordinary water, usually twice;

[0035] 3. Perform strong acid micro-corrosion light treatment to make the surface of the outer conductor light, and then wash it with ordinary water, usually twice;

[0036] 4. Perform surface activation treatment on the outer conductor with acid, and then wash with ordinary water, usually twice;

[0037] 5. Clean the outer conductor with pure water;

[0038] 6. Perform alkaline copper plating on the outer conductor in alkaline solution, and then wash it with ordinary water, usually twice;

[0039] 7. Pi...

Embodiment 2

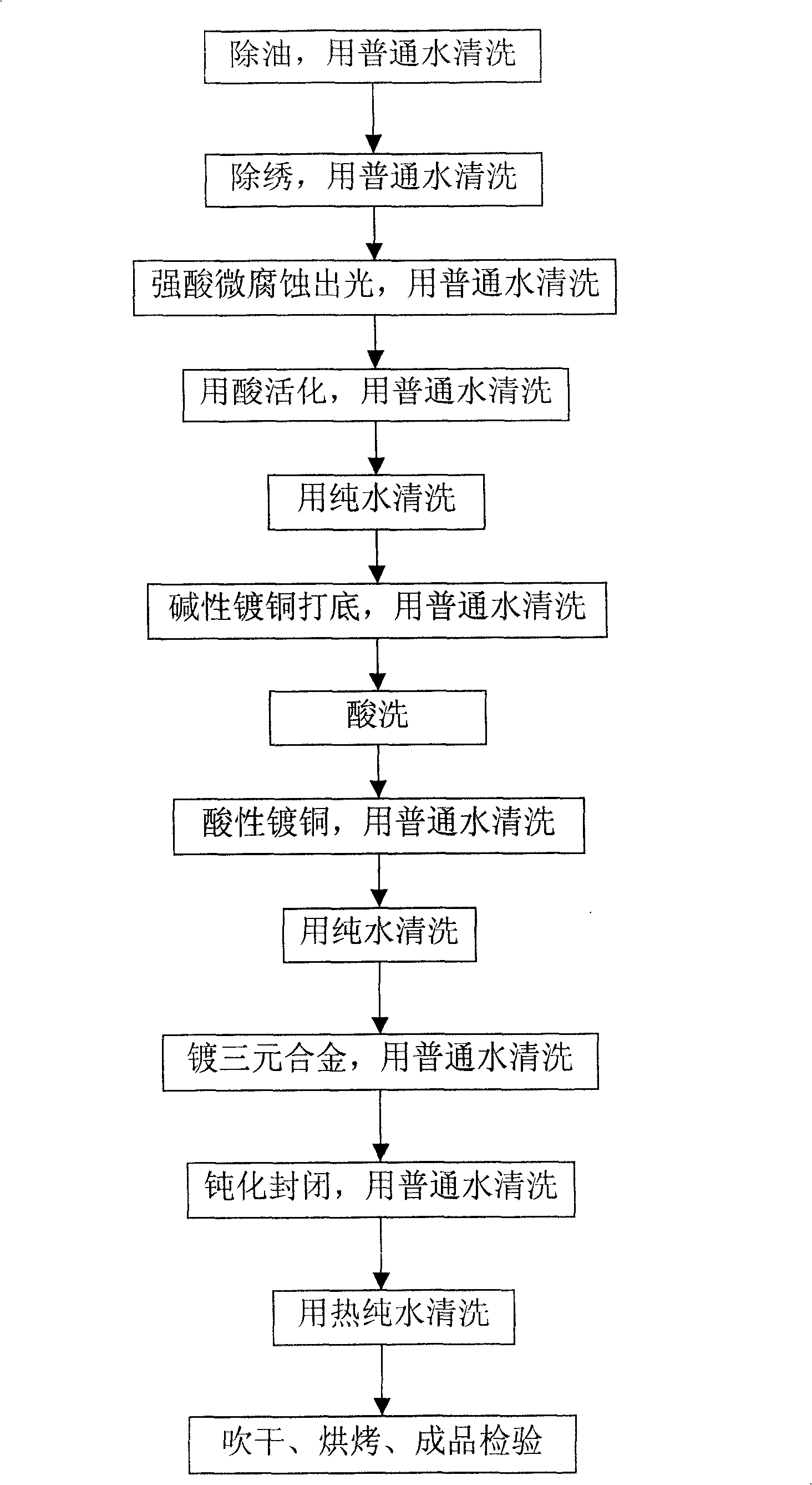

[0057] figure 2 Embodiment 2 of the method for plating the outer conductor of a semi-rigid coaxial cable with a ternary alloy according to the present invention is shown. Such as figure 2 As shown, in order to obtain a better ternary alloy coating with anti-corrosion ability, embodiment two increases the passivation sealing step on the basis of embodiment one, that is, after step 10 of embodiment one is completed, before the hot pure water cleaning step, Use chromic anhydride to passivate and seal the outer conductor coating, and wash it with ordinary water after treatment, which can remove the pores of the coating, effectively prevent the corrosive medium from corroding the outer conductor substrate through the pores of the coating, and achieve the purpose of improving the anti-corrosion ability of the coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com