Method of electronic assembly heat conduction

An electronic component and heat conduction technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of heat conduction barriers, heat conduction formation barriers, and the inability to achieve zero-gap sealing state of metal materials, achieving high heat conduction efficiency, Effect of high voltage and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

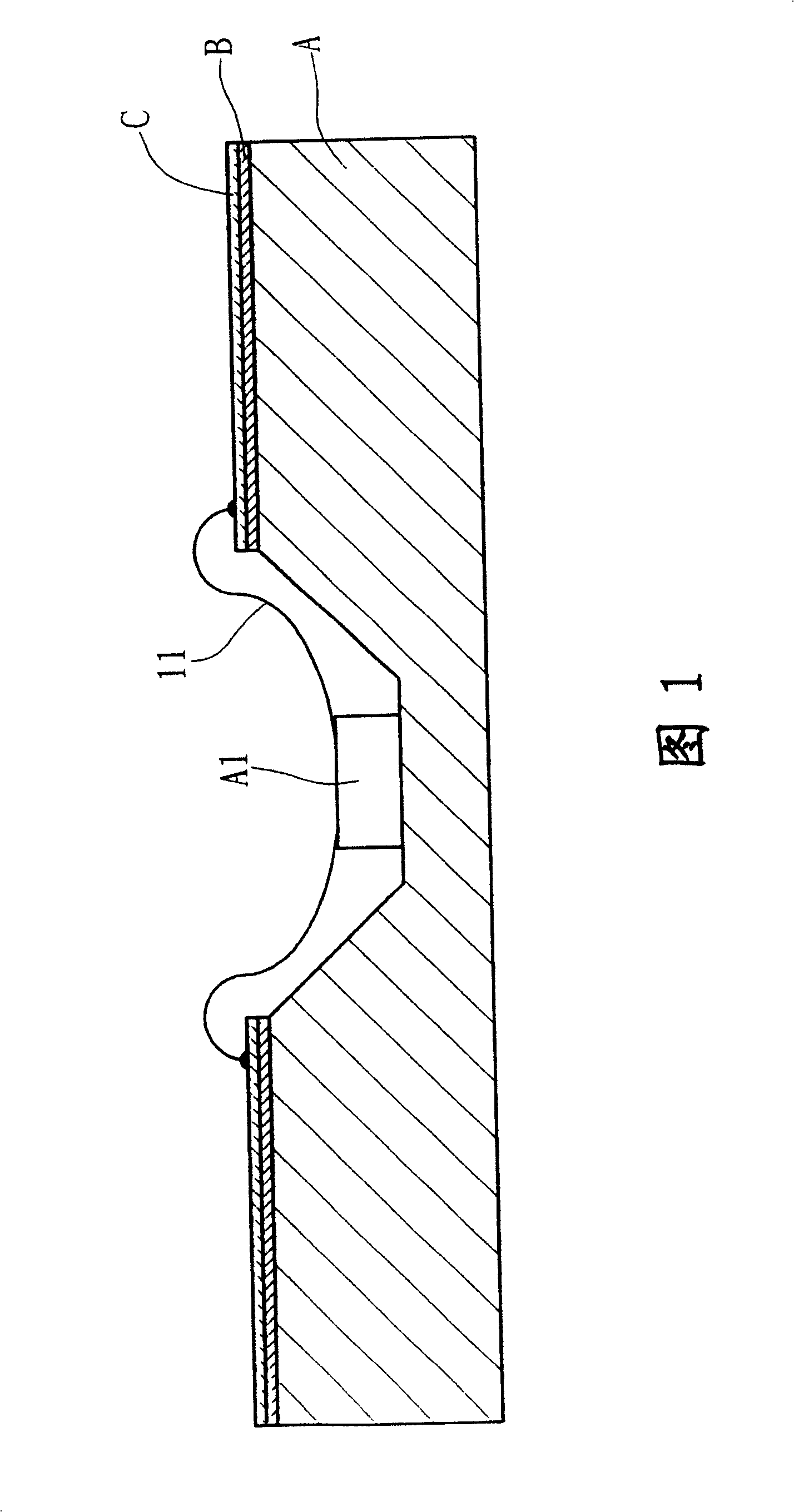

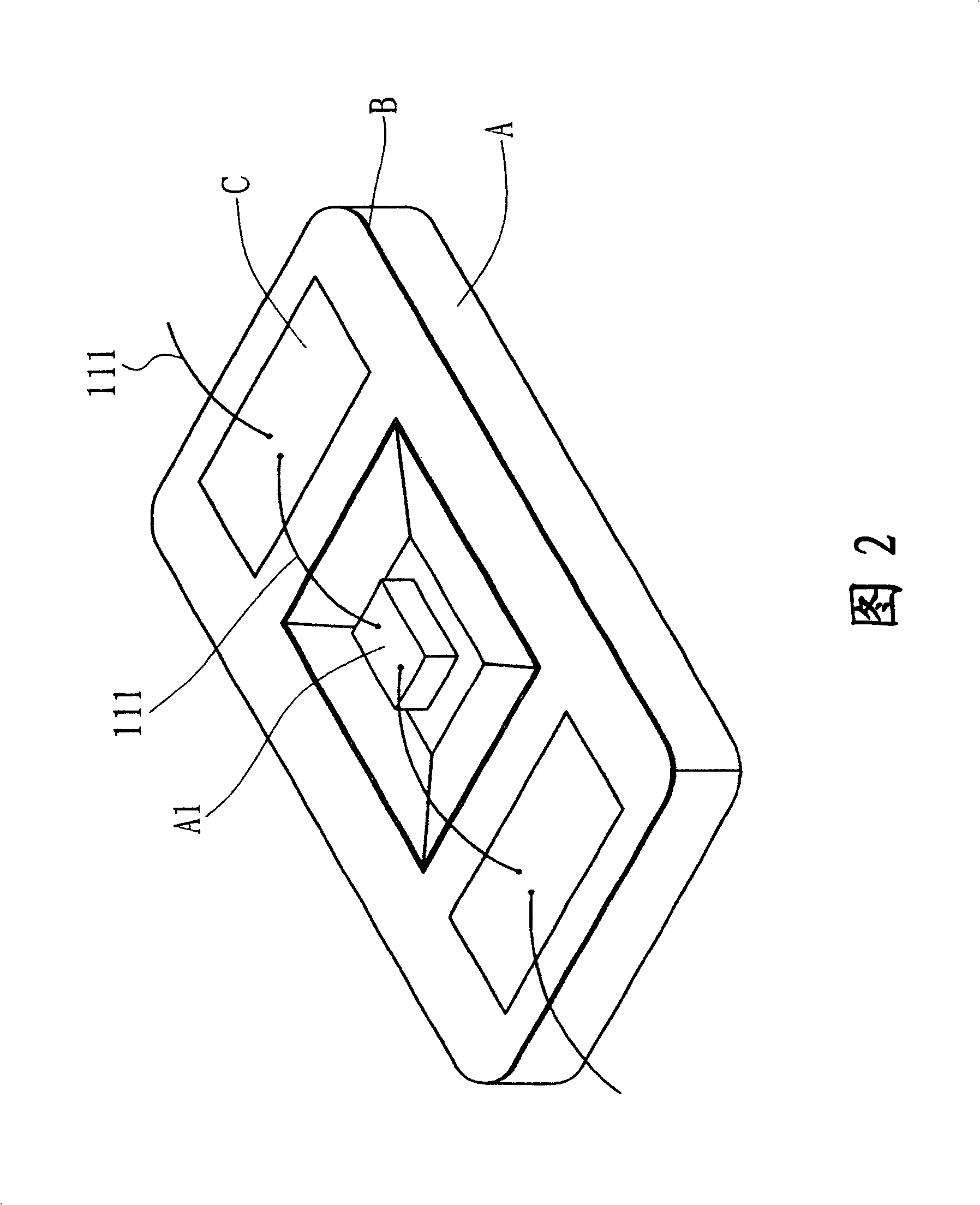

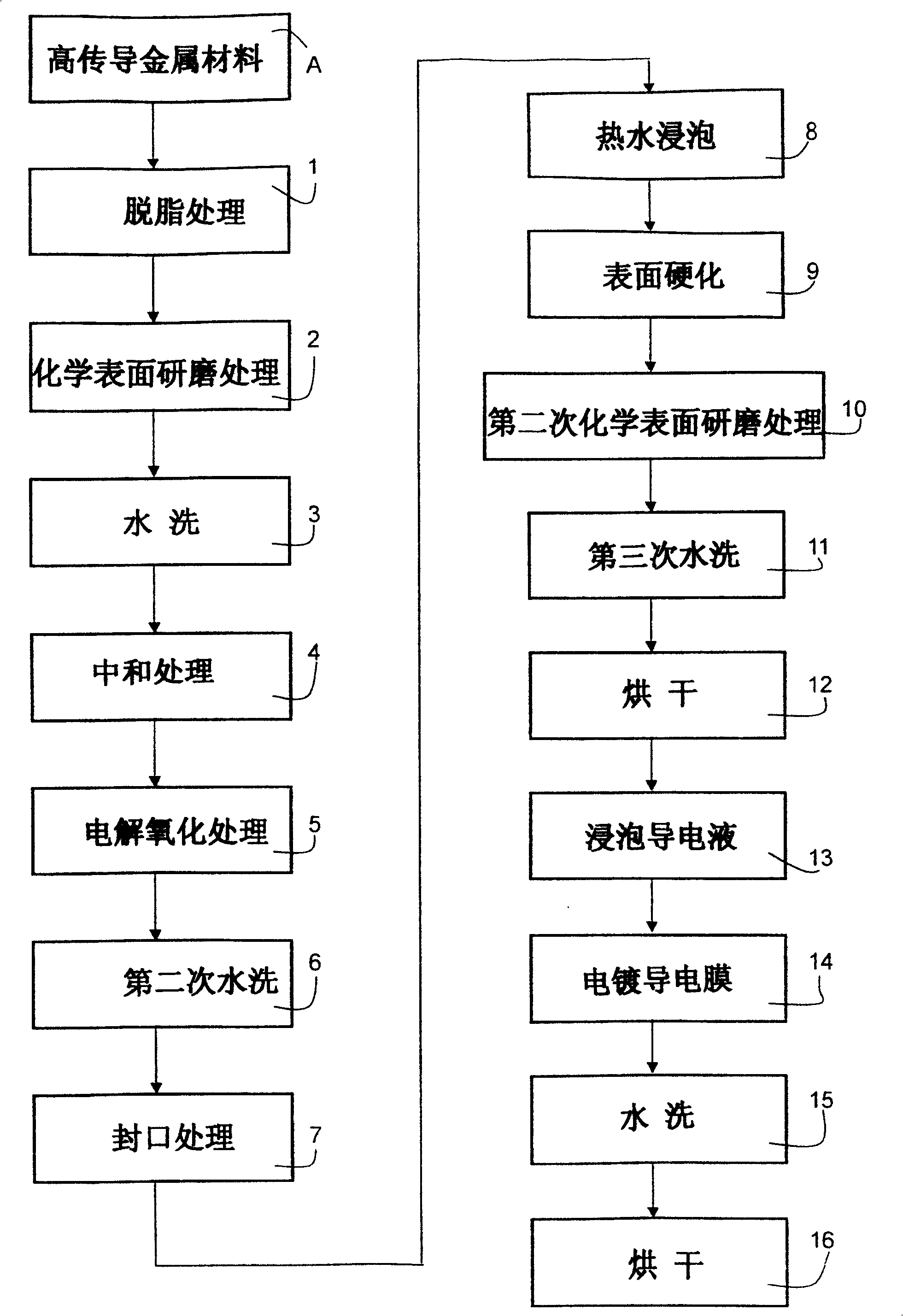

[0023] Please refer to Figure 1 and Figure 2, which is an example of the present invention when it is applied to an LED lighting device. An oxidized insulating dielectric layer B is formed on the surface of the highly conductive metal material A, and the oxidized insulating dielectric layer B has the characteristics of high temperature resistance and high voltage resistance at the same time, and then a layer is formed at a specific position on the oxidized insulating dielectric layer B as Conductive metal film C for energization, and connectable wire 111 is energized to one or more than one electronic components A1 located on the high-conductivity metal material A, when the electronic components A1 conducts electricity and generates heat energy, it can be quickly transmitted to the high-conductivity On the conductive metal material A, the heat energy generated by the electronic component A1 can be quickly taken away to achieve an excellent heat exchange effect. The aforemention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com