Dc-dc converter

A technology of power converters and generators, which is applied in the direction of output power conversion devices, DC power input conversion to DC power output, instruments, etc., and can solve problems such as irregular current interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

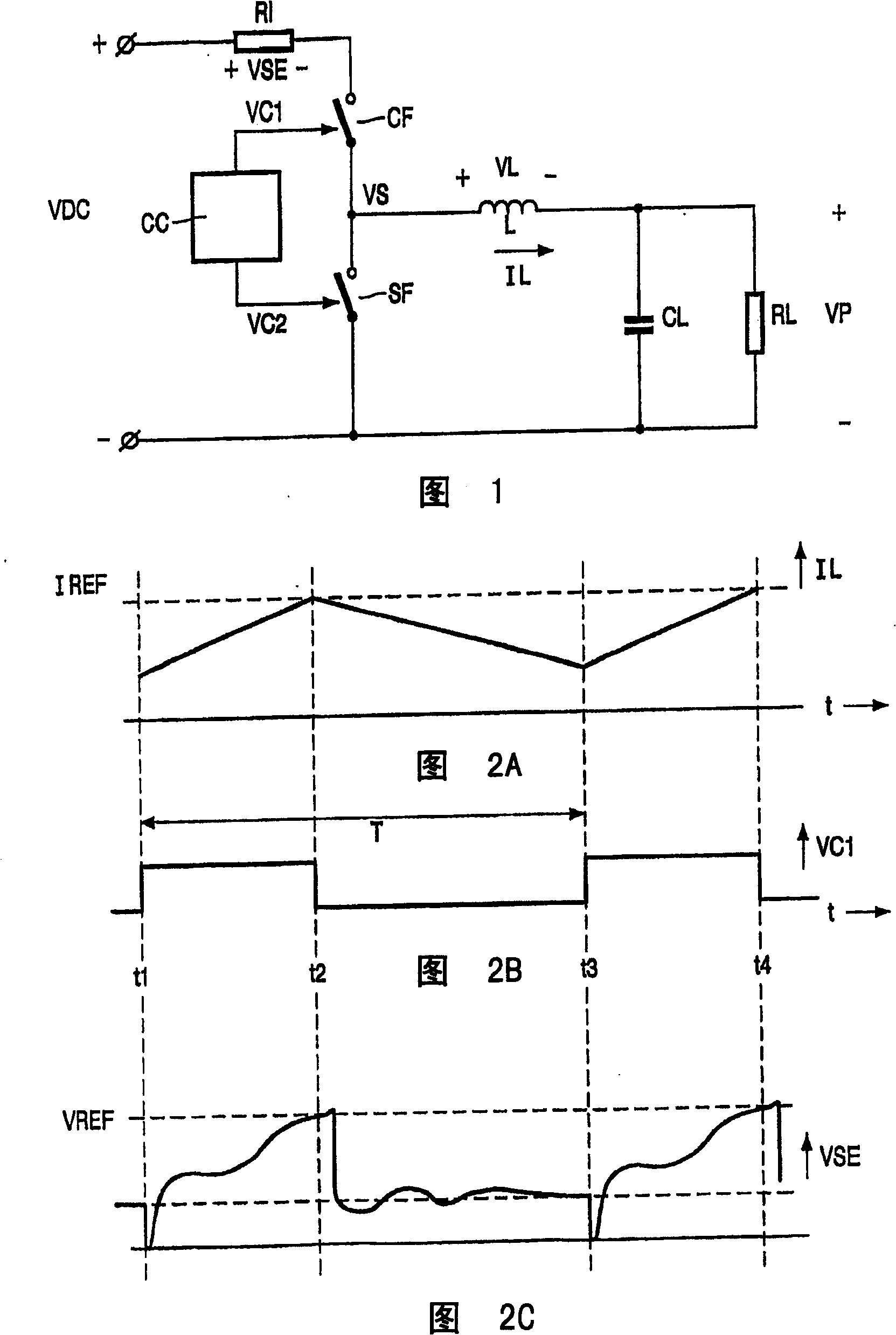

[0035] Figure 1 shows a prior art buck converter. A series arrangement of resistor R1 and controllable switches CF and SF is used to receive a DC input voltage VDC. The connection point of the switches CF and SF is connected to the load RL through the inductance L. Smoothing capacitor CL is connected in parallel with load RL. The control circuit CC controls the switches CF and SF with switching signals VC1 and VC2, respectively. The voltage across the inductor L is denoted by VL, and the current through the inductor L is denoted by IL. The voltage at the junction of the switches CF and SF is VS, and the voltage across the load RL is VP. The operation of a step-down converter is explained based on the waveforms shown in Figure 2.

[0036] 2A-2C show waveforms used to illustrate a prior art buck converter operating in continuous mode. FIG. 2A shows the current IL through the inductor L, FIG. 2B shows the control voltage VC1 controlling the switch CF, and FIG. 2C shows the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com