High malleable high wear-resisting cold process mould steel

A technology of cold work die steel and high wear resistance, applied in the field of cold work die steel, can solve the requirement of long service life that cannot meet the precision requirements of the die, the hardness, toughness and wear resistance are low, and no good mold is obtained. Co-ordination and other issues, to achieve the effect of a wide range of molds, excellent comprehensive performance, and reduced material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment the present invention is described in further detail:

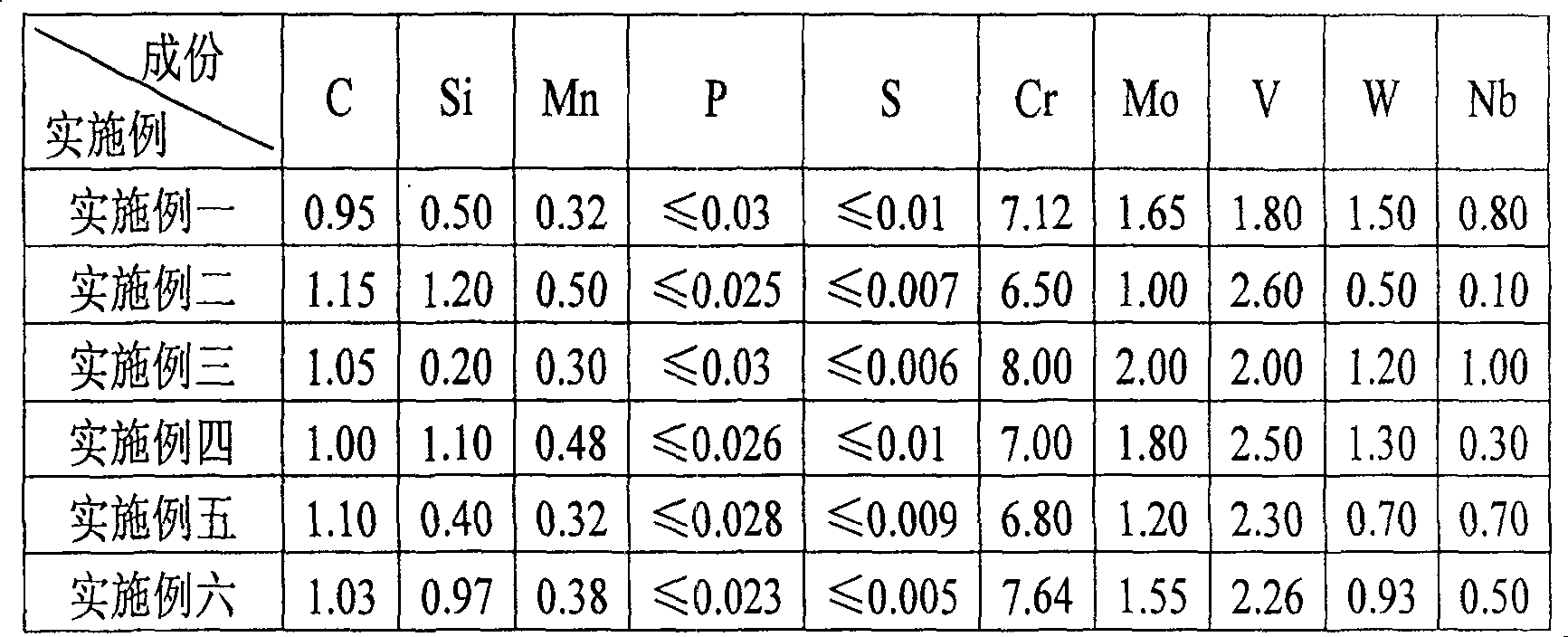

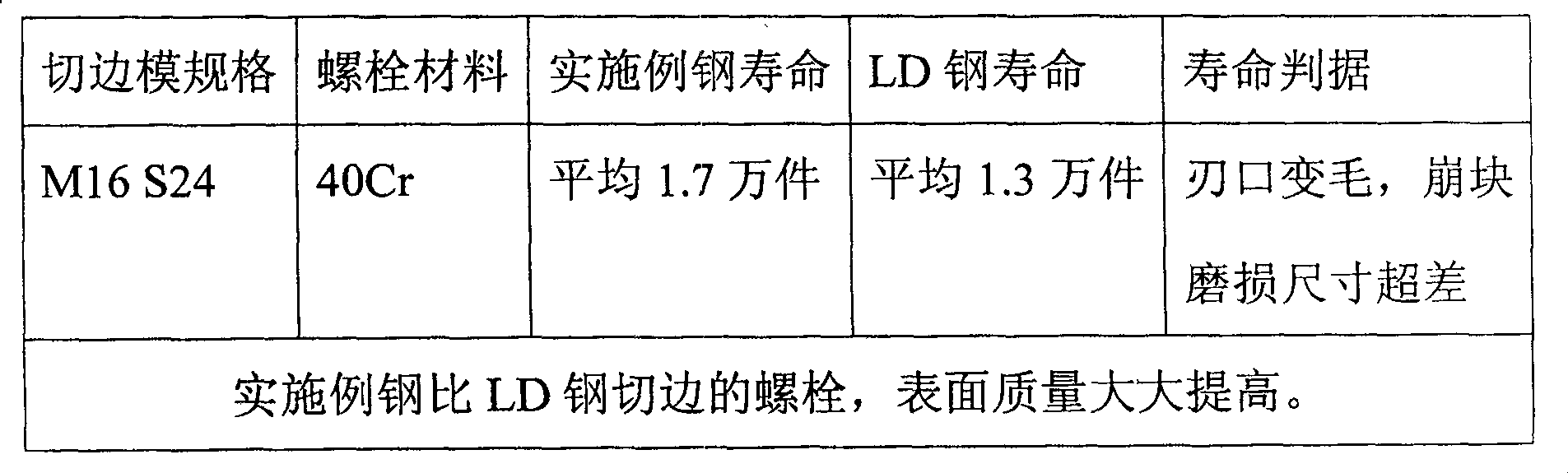

[0019]

[0020] The smelting raw materials of steel in the embodiment are: high-speed steel, mold steel return material, industrial pure iron, ferro-tungsten, ferro-molybdenum, ferro-chrome, ferro-vanadium, ferro-niobium, etc., after 3 tons of intermediate frequency + electroslag remelting → steel ingot → fast forging , Forging machine deformation → square billet → rolling mill finished product → annealing → finishing → φ45mm round steel is the finished material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com