Preparation method for nanometer magnesium oxide

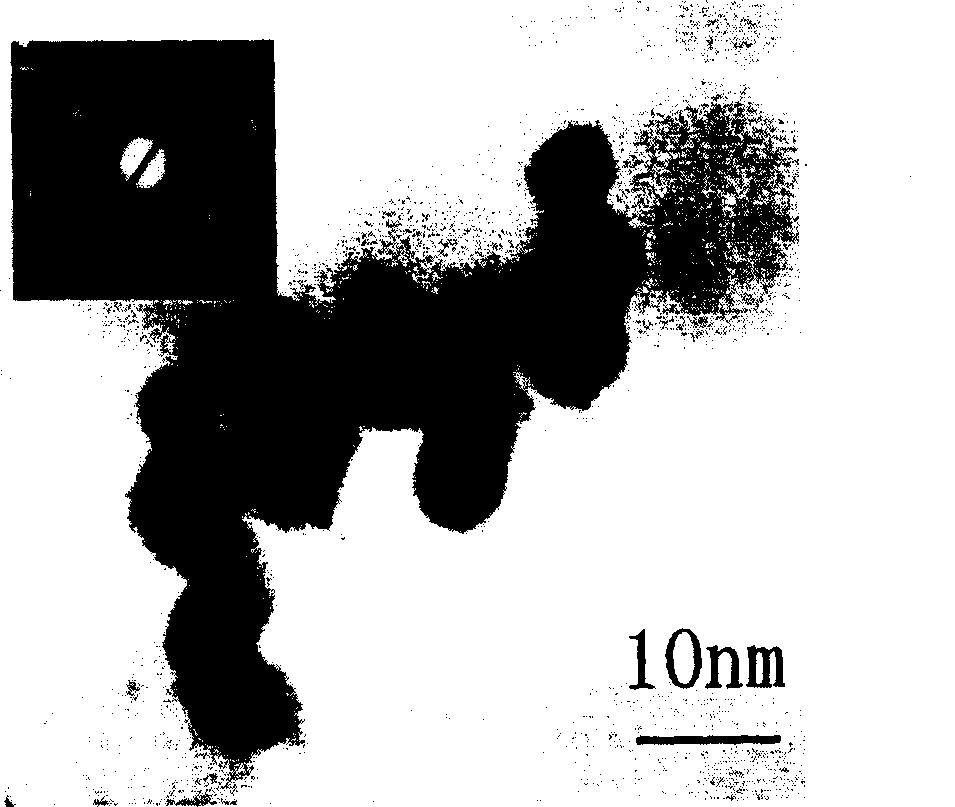

A technology of nano-magnesium oxide and magnesium salt, which is applied in the direction of magnesium oxide, etc., can solve the problems of limiting the production and application of nano-magnesia, difficulty in obtaining ultra-fine magnesium oxide, and difficult control of process conditions. The effect of small diameter and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Take 0.4855g of magnesium chloride, dissolve it in 6ml of water in an autoclave with a volume of 20ml, then add 0.0179g of disodium ethylenediaminetetraacetic acid and stir to make solution A, and then weigh 0.3126g of sodium oxalate to make it 6ml of solution B, add B to A and mix evenly under stirring, hydrothermal reaction occurs at 160°C for 10 hours, after natural cooling, centrifugal washing until there is no chloride ion (tested with silver nitrate) to obtain the precursor, vacuum at room temperature After drying for 24 hours, the dried precursor was burned in a muffle furnace. This process was divided into two steps: the first step: burning at 450°C for 1.5h; the second step: raising the temperature to 600°C for 1.5h. That is, white nano-sized magnesium oxide crystals are obtained.

Embodiment 2

[0013] Example 2: Take 1.2108g of magnesium chloride, dissolve it in 7.5ml of water in an autoclave with a volume of 20ml, then add 0.0446g of disodium ethylenediaminetetraacetate and stir to form solution A, and then weigh 0.8064g of sodium oxalate to prepare Prepare 7.5ml of solution B, add B to A and mix evenly under stirring, hydrothermal reaction occurs at 100°C for 4 hours, and after natural cooling, centrifuge and wash until there is no chloride ion (tested with silver nitrate) to obtain the precursor. After vacuum drying at room temperature for 24 hours, the dried precursor is fired in a muffle furnace. This process is divided into two steps: the first step: burning at 400°C for 1 hour; the second step: raising the temperature to 600°C and burning for 2 hours. That is, white nano-sized magnesium oxide crystals are obtained.

Embodiment 3

[0014] Example 3: Take 1.5248g of magnesium chloride, dissolve it in 7ml of water in an autoclave with a volume of 20ml, then add 0.0559g of disodium ethylenediaminetetraacetic acid and stir to make solution A, and then weigh 1.005g of sodium oxalate to make it 7ml solution B, add B to A and mix evenly under stirring, hydrothermal reaction occurs at 100°C for 6 hours, after natural cooling, centrifuge and wash until there is no chloride ion (tested with silver nitrate) to obtain the precursor, vacuum at room temperature After drying for 24 hours, the dried precursor was burned in a muffle furnace. This process was divided into two steps: the first step: burning at 450°C for 1.5h; the second step: raising the temperature to 600°C for 1.5h. That is, white nano-sized magnesium oxide crystals are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com