Heat exchanger

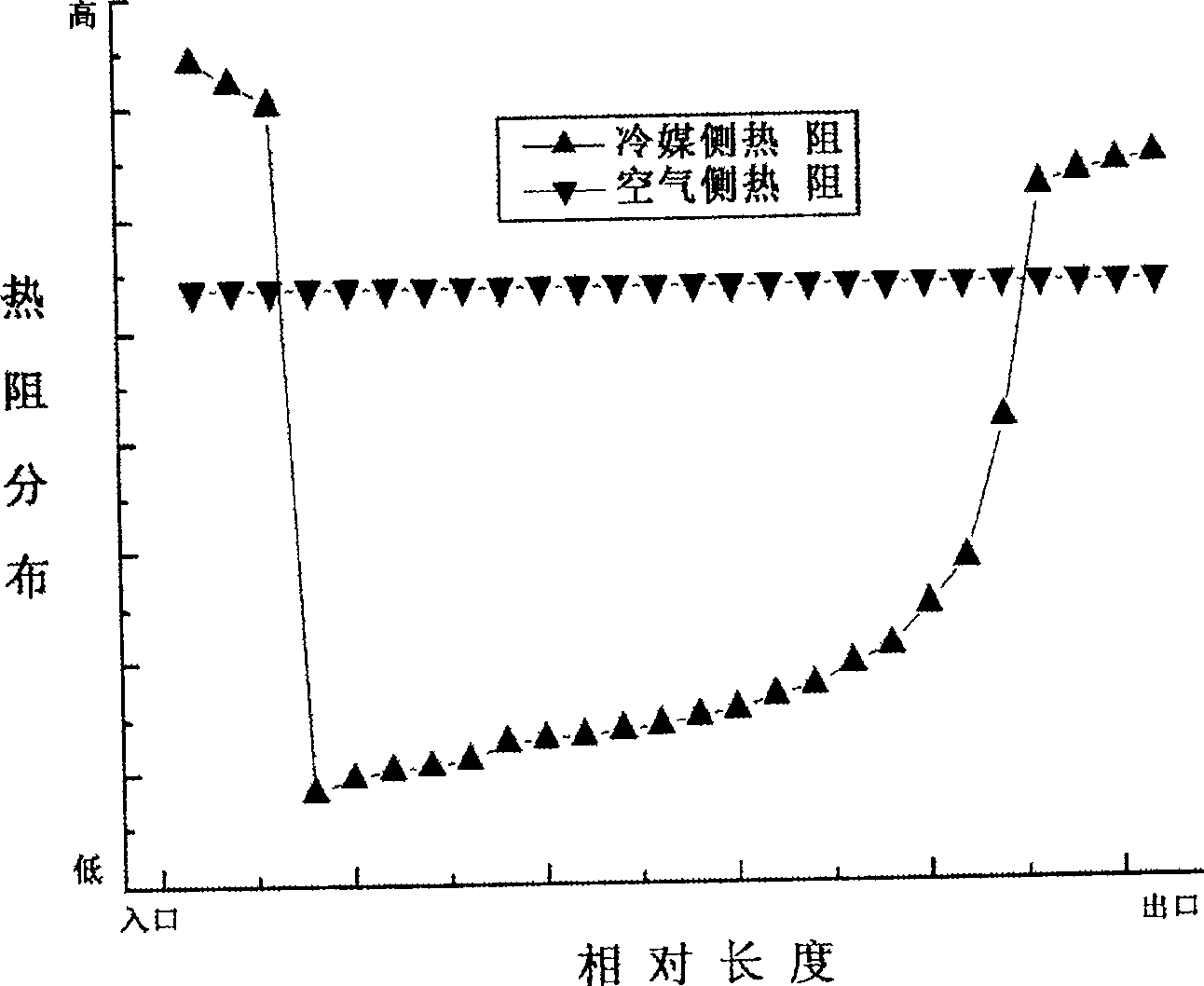

A technology of heat exchangers and heat exchange tubes, applied in the direction of heat exchanger shells, indirect heat exchangers, heat exchanger types, etc. High coefficient and other problems, to achieve the effect of simple structure, uniform heat transfer coefficient and pressure drop, and increase heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

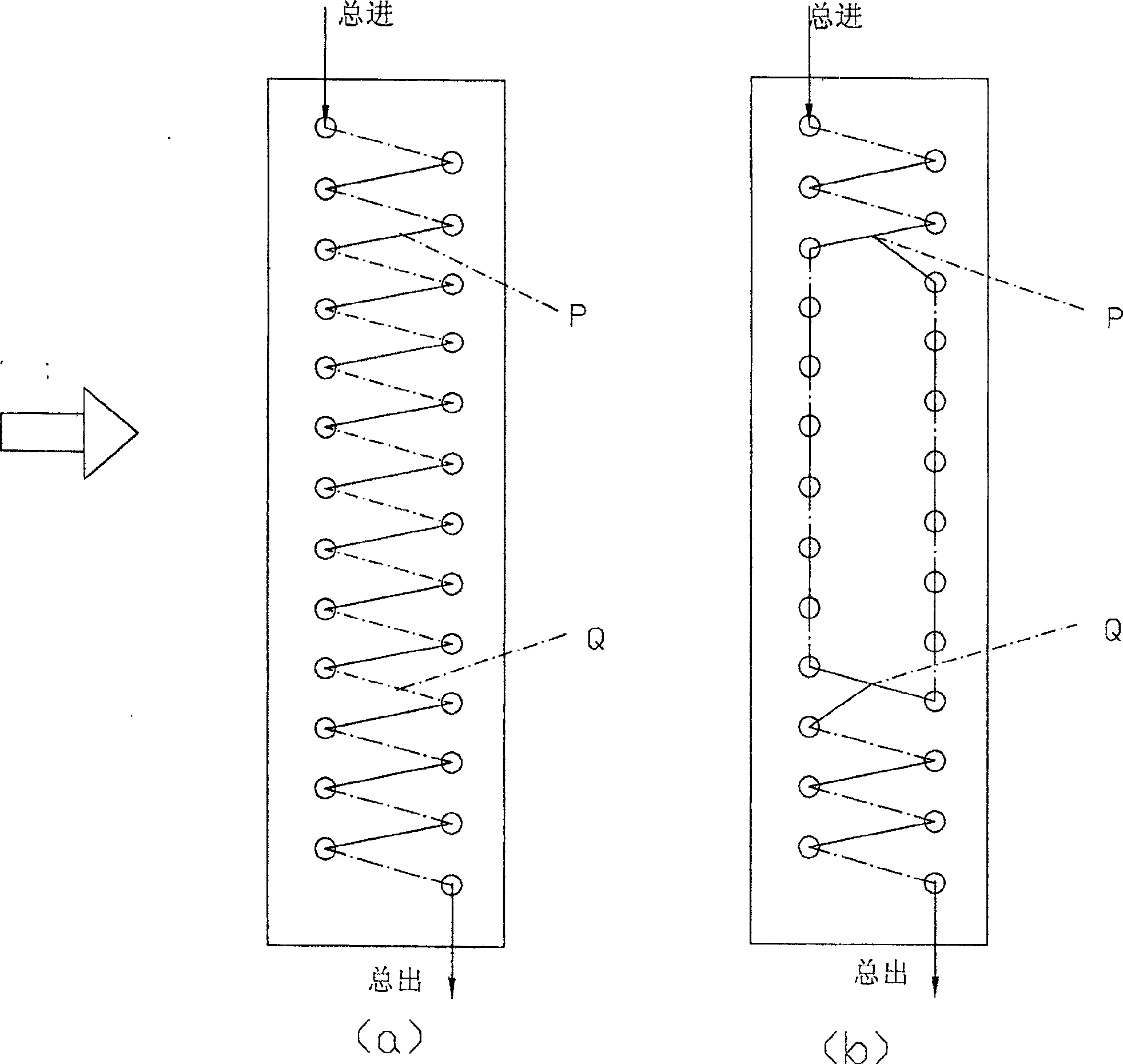

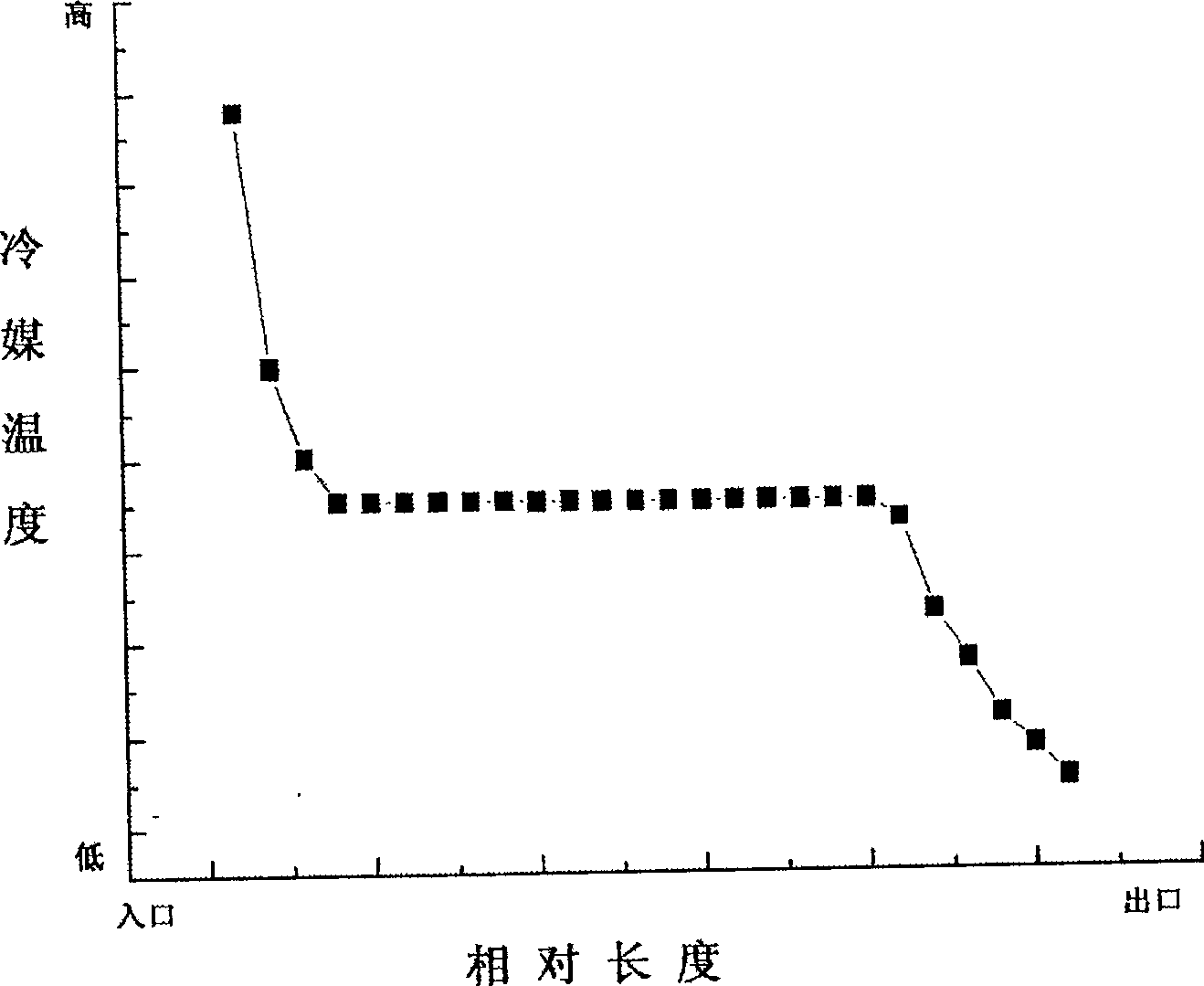

[0019] The structure diagram of the present invention is as figure 1 As shown in (b), this embodiment is used as a condenser in an air conditioner, including a number of heat exchange tubes flowing in the refrigerant and fins fixed on it, wherein the position P at the beginning of the two-phase region At , the outlets of the single heat exchange tubes communicate with the inlets of several heat exchange tubes respectively, and at the position Q where the two-phase area ends, the outlets of several heat exchange tubes communicate with the inlets of the single heat exchange tubes respectively. The phase state at the refrigerant inlet of the condenser is a gaseous state, the phase state after the two-phase region starts is a vapor-liquid mixed state, and the phase state after the two-phase region ends is a liquid state.

[0020] In this embodiment, at the position P at the beginning of the two-phase area, the outlet of the single-channel heat exchange tube is respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com