Device for preventing hydraulic rock breaker against scuffing

A technology of hydraulic pistons and rock breakers, which is applied in the direction of striking tools, light impact tools, manufacturing tools, etc., can solve the problems of increased oil leakage, easy wear, and increased friction surface gaps, etc., to reduce oil leakage , prevent scratches, prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

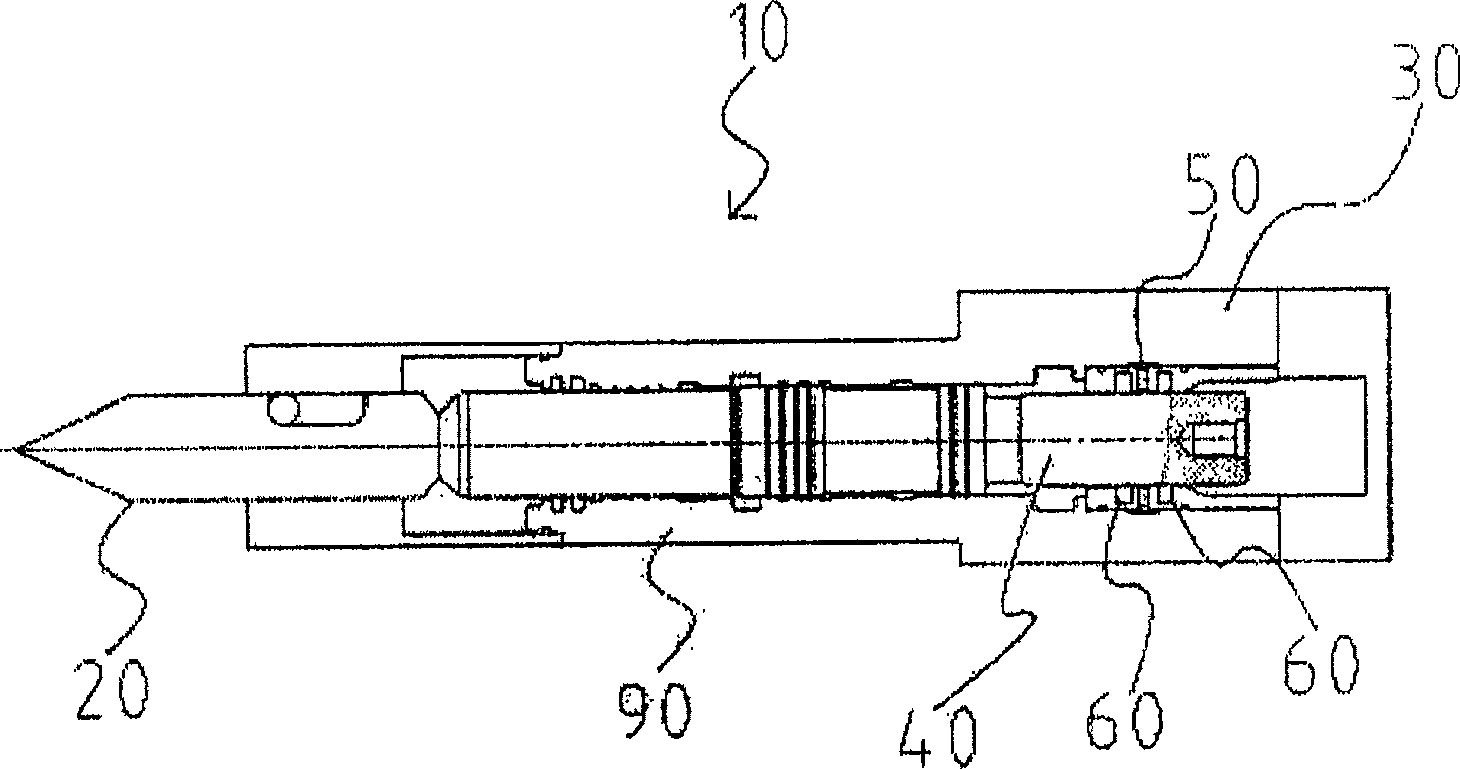

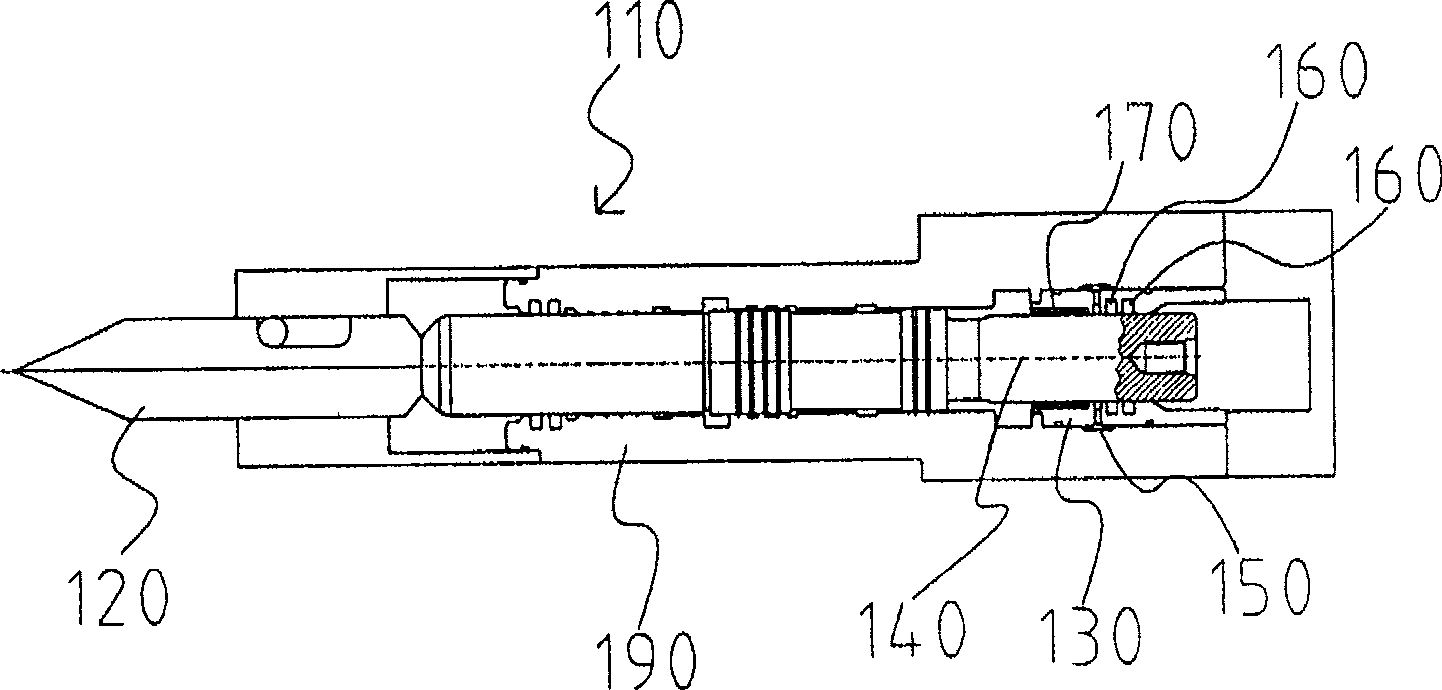

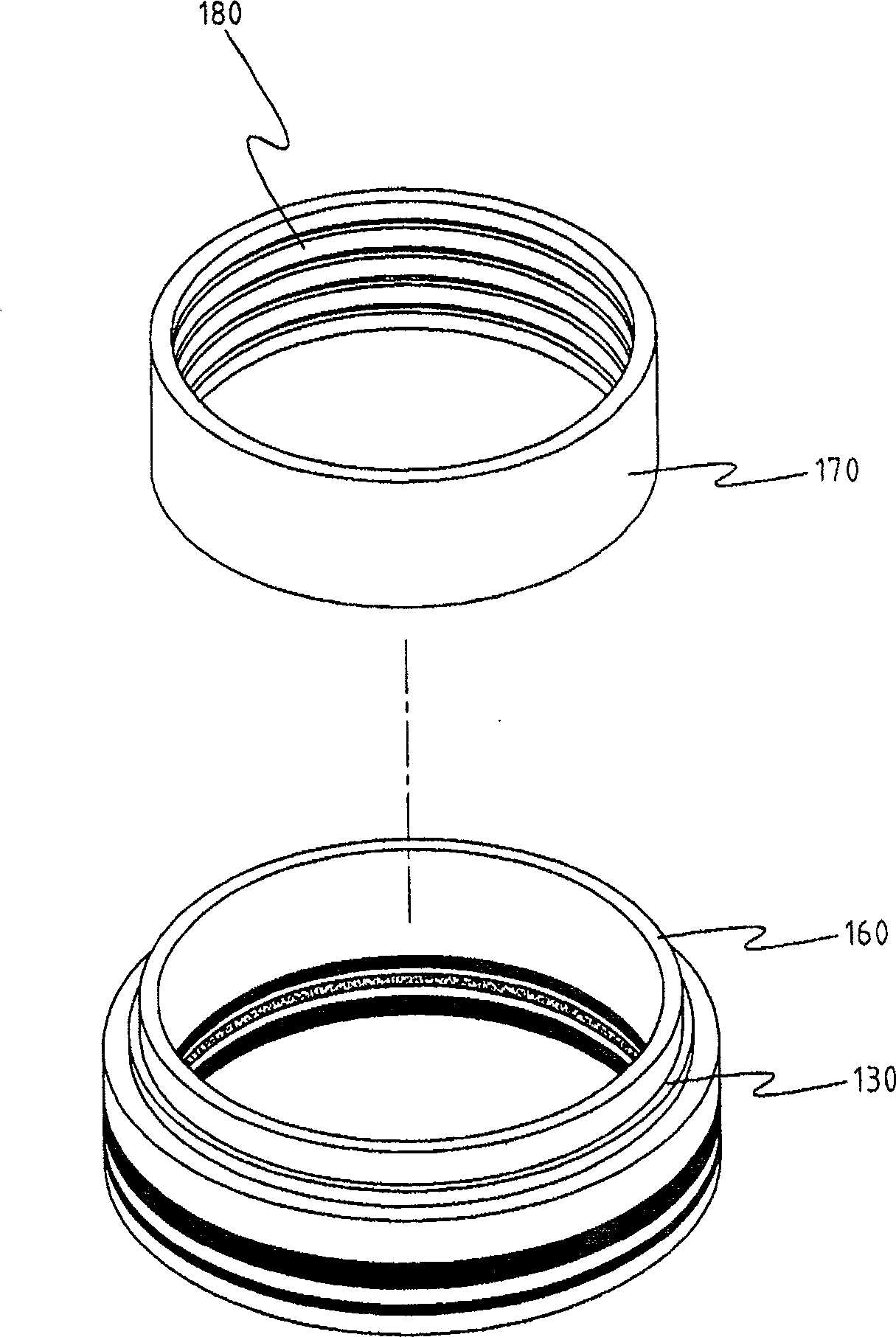

[0021] figure 2 It is a schematic front sectional view of the device for preventing the hydraulic lithotripter piston from being scratched according to the present invention, image 3 and Figure 4 It is a perspective view and a partially enlarged schematic view of the bush integrated with the retainer in the present invention. Below the cylinder 190 of the hydraulic lithotripter 110, a chisel 120 for crushing objects is arranged, and the retainer 130 is arranged inside the cylinder 190 on the upper side of the above-mentioned chisel 120, and a hydraulic piston 140 is arranged on its inner side and moves up and down to strike The chisel 120 is provided with a low-pressure pipeline 150 and a sealing member 160 between the retaining ring 130 and the friction surface of the hydraulic piston 140 .

[0022] The above-mentioned hydraulic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com