Method for preparing metal magnesium from magnesium mineral

A technology of metal magnesium and minerals, applied in the field of production of metal magnesium, can solve problems such as difficulty in ensuring that electrolytic raw materials do not absorb water, increase in investment per unit of product, and low output rate of magnesium chloride, so as to facilitate industrial operation, improve reaction efficiency and production efficiency , Improve the effect of electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

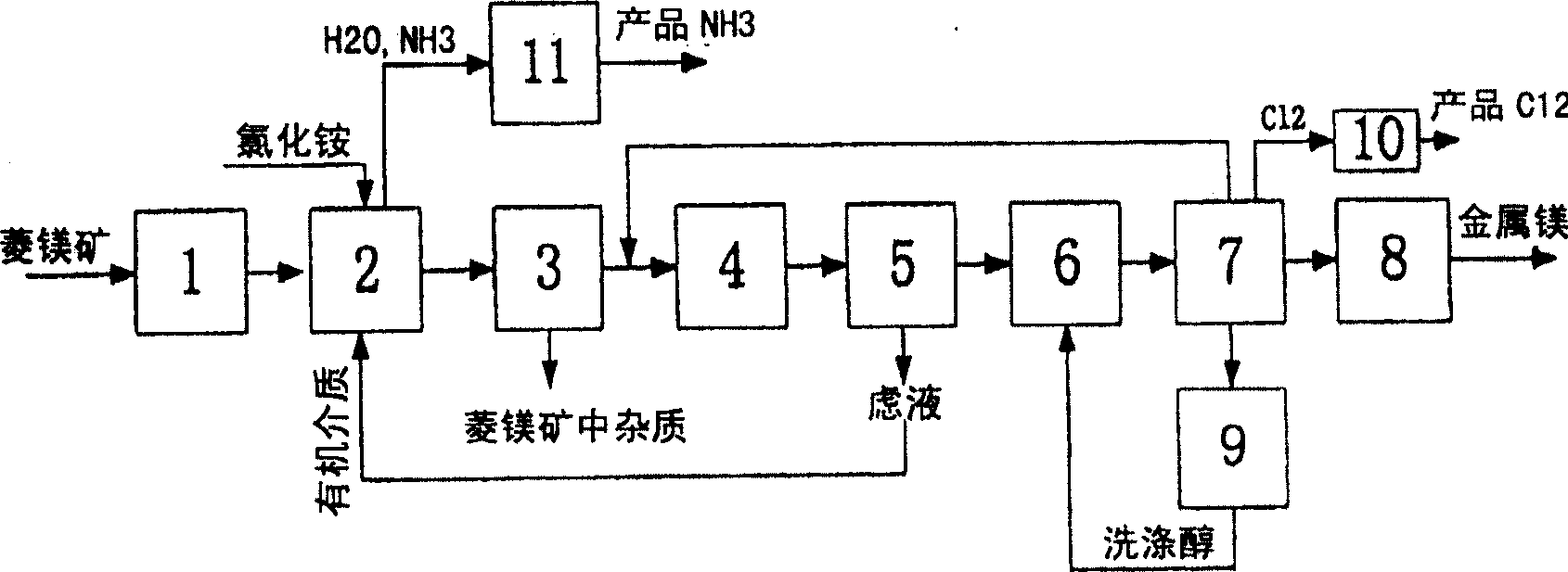

[0046] Such as figure 1 Shown, be the present invention by magnesium-containing ore and prepare metallic magnesium process flow chart, wherein have: rapid fluidized activation roasting device 1; Chlorination reaction distillation dehydration reactor 2; Filtration equipment 3; Fluidized reaction crystallizer 4 ; Filtration equipment 5; Washing equipment 6; Fast fluidized drying equipment 7; Deamination electrolysis coupling reaction device 8; Cooling recovery tower 9; Each process is connected with the outside world in a closed and isolated manner according to the process.

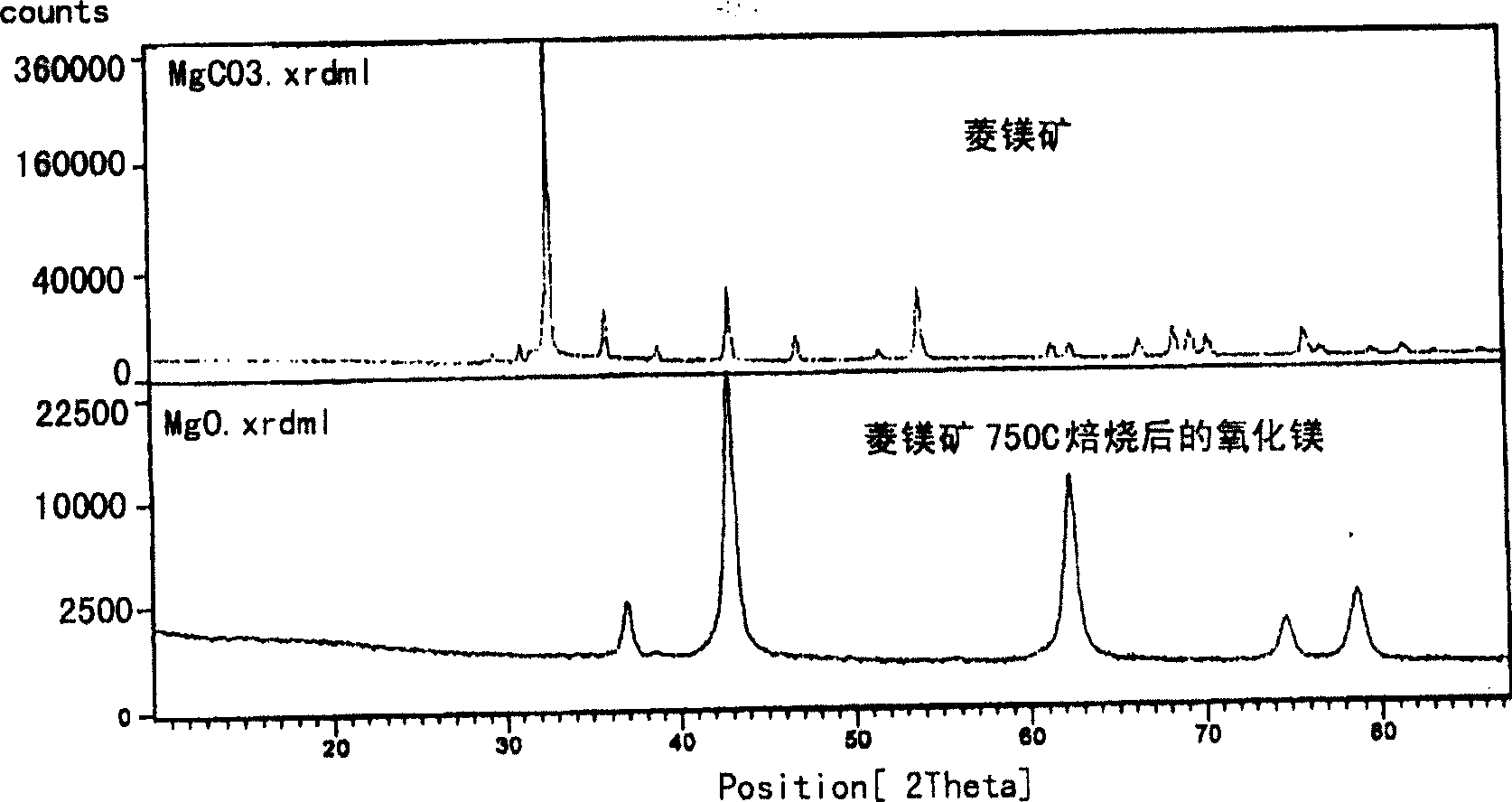

[0047] Magnesium-containing minerals take magnesite as an example to further describe and illustrate the process technology for preparing magnesium metal of the present invention. The chemical analysis of magnesite is shown in Table 1 as follows:

[0048] Table 1. Chemical analysis of magnesite

[0049] composition MgO SiO2 CaO Fe203+Al203 content(%) 46.0 0.8 1.2 0.6

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com