Magnetic target slow-release catopril and its preparing method

A captopril and sustained-release technology, which is applied in the field of magnetically targeted sustained-release captopril and its preparation, can solve the problems of preparing captopril sustained-release preparations that have not been described or mentioned, etc. To achieve the effect of reducing dosage, enhancing specificity and improving curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Add 3.0795g of Mg(NO 3 ) 2 ·6H 2 O and 2.2507g of Al(NO 3 ) 3 9H 2 O is made into the mixed salt solution A that Mg / Al molar ratio is equal to 2 with 50ml water; In addition, the NaOH of 1.5g and the former drug of captopril of 2.6097g are made into mixed alkali solution B with 150ml water, and then 0.0576g of MgFe 2 o 4 put into it;

[0032] 2. In N 2 Slowly drop the mixed salt solution A into the vigorously stirred mixed alkali solution B under protection, and stop adding when the pH value is around 10;

[0033] 3. The obtained slurry was crystallized at 25° C. for 48 hours, suction filtered, washed, and vacuum-dried at room temperature for 72 hours to obtain a magnetic captopril sustained-release preparation. The water used in the process is decarbonized deionized water.

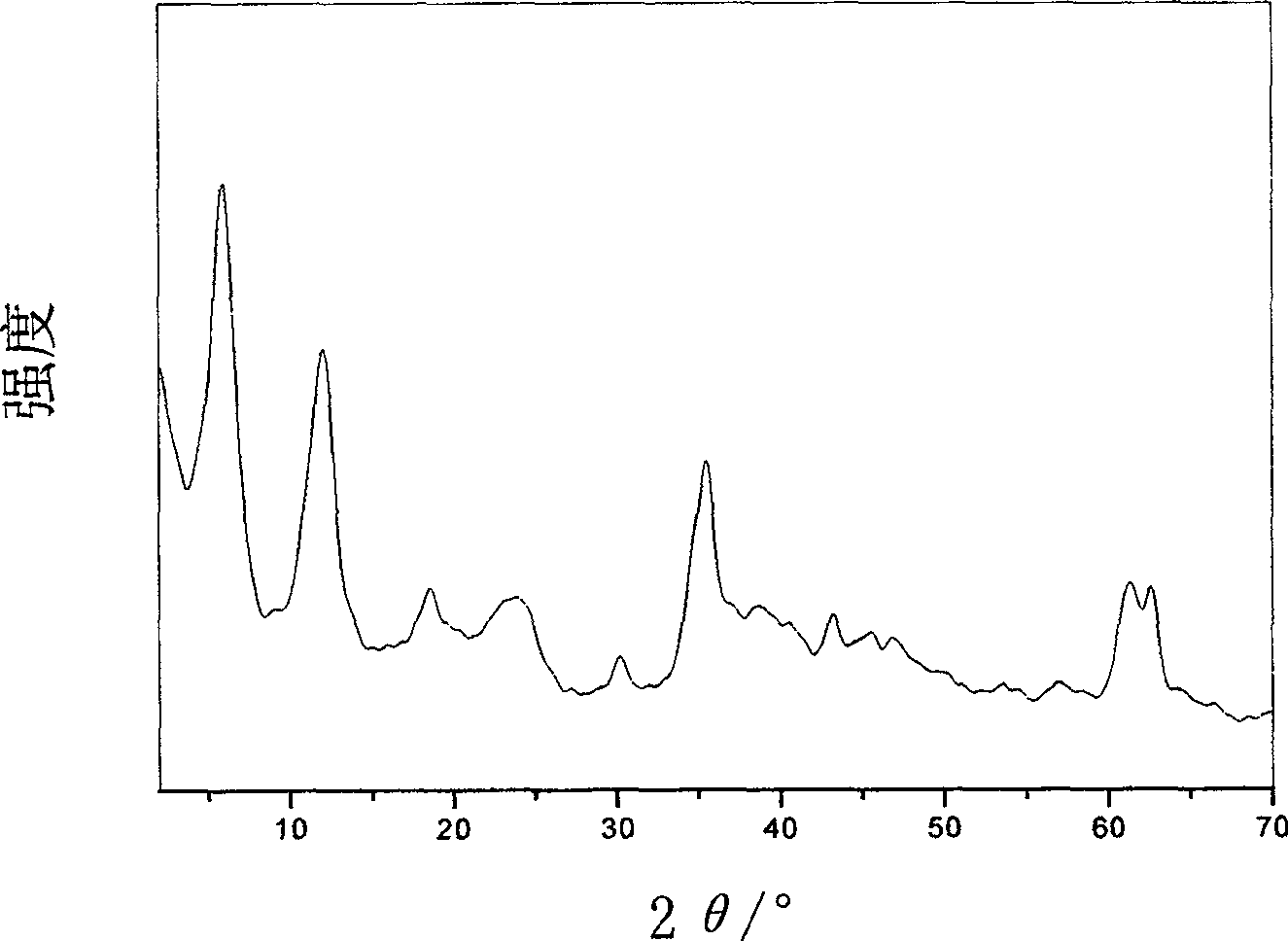

[0034] figure 1 Cpl-LDHs / MgFe 2 o 4 X-ray powder diffraction characterization results, with the crystal structure of hydrotalcite-like materials.

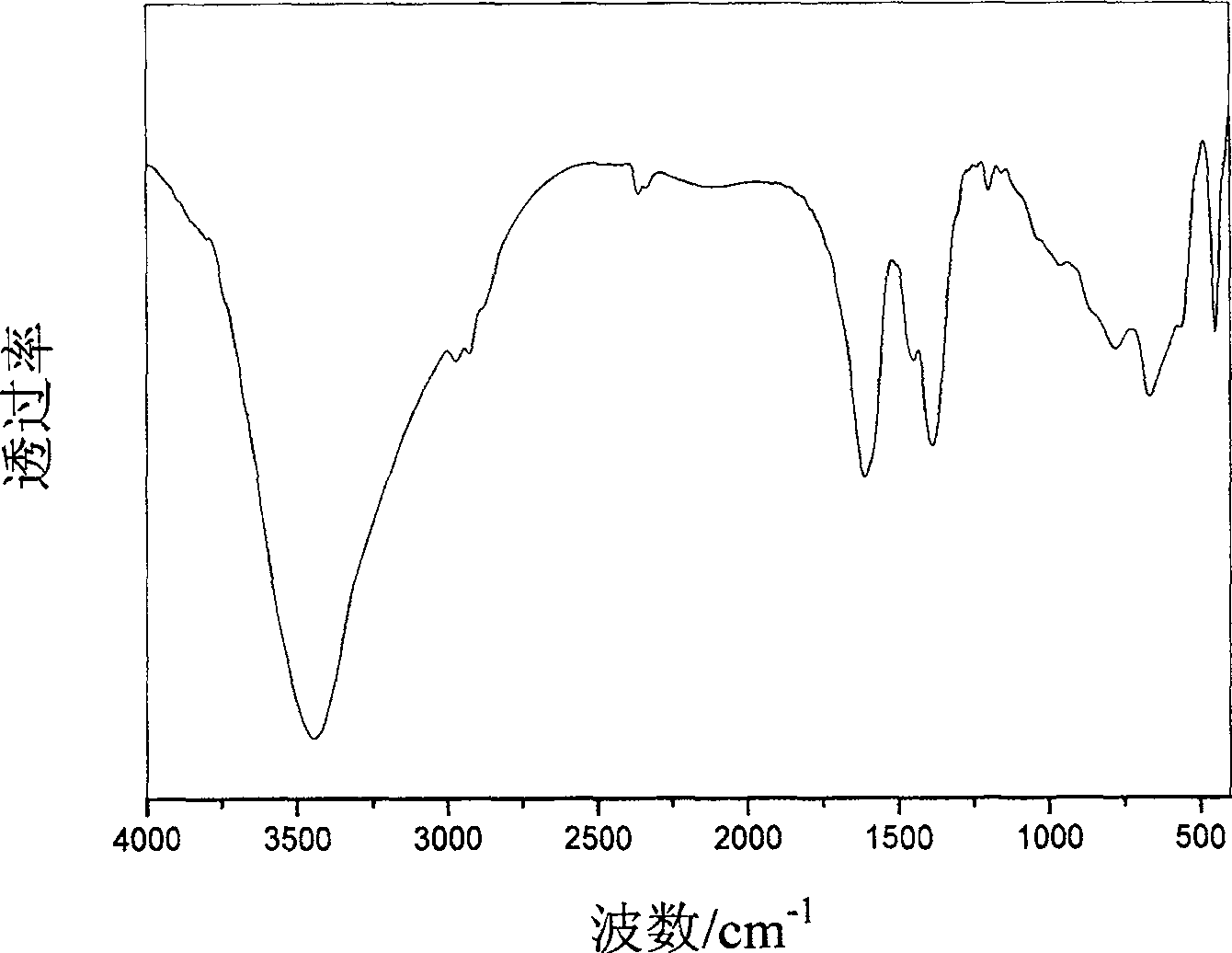

[0035] figure 2 Cpl-LDHs / MgFe...

Embodiment 2

[0039] MgFe in embodiment 1 step 1 2 o 4 Use NiFe 2 o 4 Instead, other parts are the same as in Example 1.

[0040] The sample obtained is analyzed in the same manner as in Example 1, and its empirical chemical formula is: [Mg 0.632 al 0.368 (OH) 2 ](C 9 h 14 NO 3 S 2- ) 0.0736 (CO 3 2- ) 0.1104 0.6H 2 O / (NiFe 2 o 4 ) 0.0152 , the content of captopril is 20.40%, and the specific saturation magnetization is 1.30emu / g.

Embodiment 3

[0042] MgFe in embodiment 1 step 1 2 o 4 with Fe 3 o 4 Instead, other parts are the same as in Example 1.

[0043] The sample obtained is analyzed in the same manner as in Example 1, and its empirical chemical formula is: [Mg 0.642 al 0.358 (OH) 2 ](C 9 h 14 NO 3 S 2- ) 0.0667 (CO 3 2- ) 0.1123 0.8H 2 O / (Fe 3 o 4 ) 0.0194 , the content of captopril is 21.72%, and the specific saturation magnetization is 3.64emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com