Method of producing seasoning

A manufacturing method and seasoning technology, which is applied in the field of seasoning manufacturing, can solve the problems of not being able to impart a strong taste and not cover up, and achieve the effect of excellent heating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

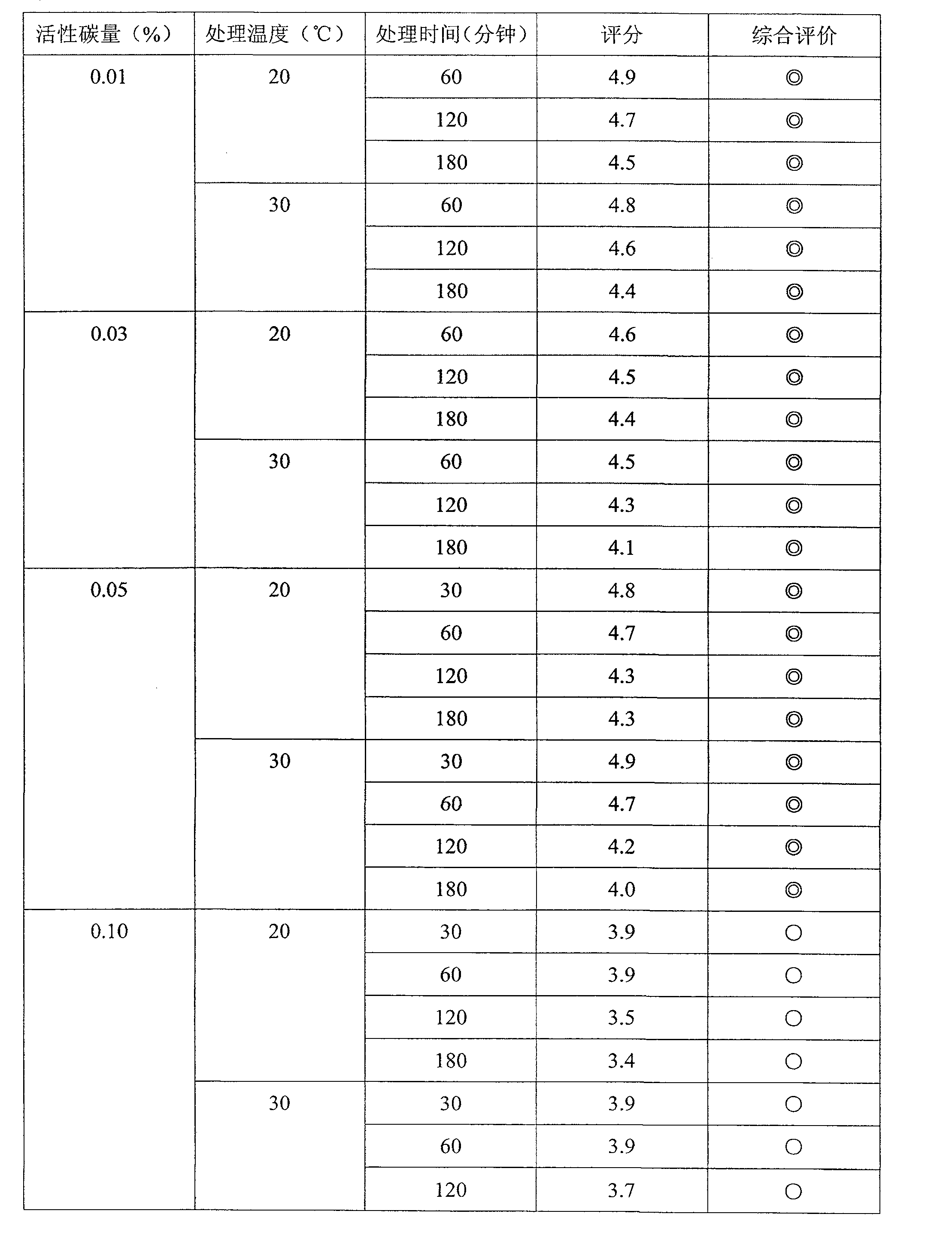

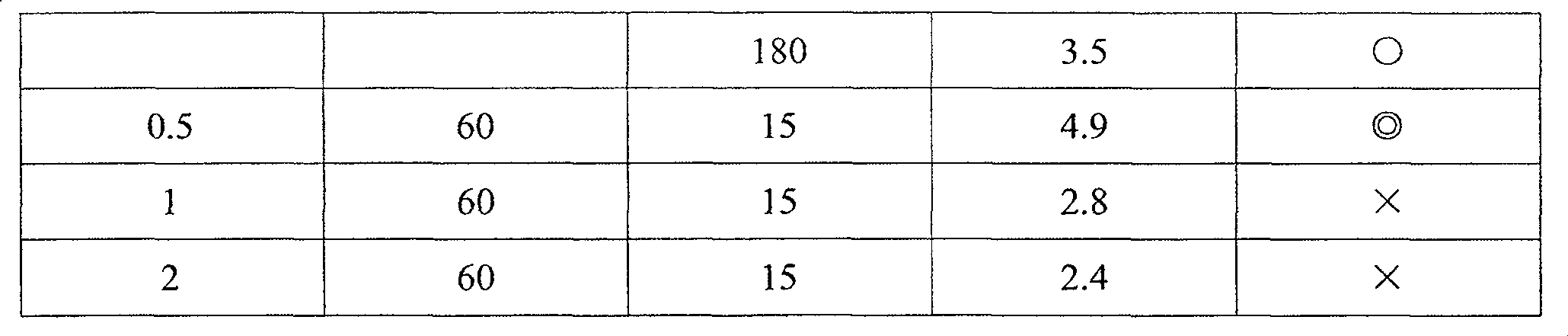

[0041] The research of embodiment 1 decomposition time

[0042] 60Kg expanded defatted soybeans, 47Kg L.lactis AJ110212 (FERM BP-8552) culture solution (pH6.3) was dropped into a mixer (mazelar (manufactured by Industrial Machinery Co., Ltd.)) and fully mixed, then A.sojaeAJ117552 ( FERM P-19637) spores were mixed to make 2×10 6 pieces / g of raw materials. Put the above mixture into a ventilated koji making machine, and cultivate it for 45 hours while keeping the product temperature at 30-32°C. 1,500 g of the obtained koji and 4,050 g of salt water having a salt concentration of 15.6% by weight were put into a glass bottle. As salt, NaCl M (manufactured by Naikai Salt Industry Co., Ltd.) was used. Put the glass bottle into a constant temperature tank, and carry out fermentation at 35° C. for 10 to 20 days. In addition, stir once a day during fermentation to evenly disperse the koji floating on the top. After 10, 12, 14, 16, 18, and 20 days from the start of fermentation, s...

Embodiment 2

[0049] The research of embodiment 2 decomposition temperature

[0050] 60Kg expanded defatted soybeans, 47Kg L.lactis AJ110212 (FERM BP-8552) culture solution (pH6.3) was dropped into a mixer (mazelar (manufactured by Industrial Machinery Co., Ltd.)) and fully mixed, then A.sojaeAJ117552 ( FERM P-19637) spores were mixed to make 2×10 6 pieces / g of raw materials. Put the above mixture into a ventilated koji making machine, and cultivate it for 45 hours while keeping the product temperature at 30-32°C. 189 g of the obtained koji and 511 g of salt water having a salt concentration of 15.6% by weight were put into a glass bottle. As salt, NaCl M (manufactured by Naikai Salt Industry Co., Ltd.) was used. Put the glass bottle into a constant temperature tank, and ferment for 14 days at 31-41°C. In addition, stir once a day during fermentation to evenly disperse the koji floating on the top. After the fermentation is over, the residue is removed with a filter cloth to obtain raw...

Embodiment 3

[0057] Example 3 Research on the Proportion of Cooked Defatted Soybeans

[0058]The puffed defatted soybeans cost a manufacturing cost because they are processed in an extruder. It is possible to reduce the cost of raw materials by blending a part of steamed defatted soybeans. This time, the raw materials of puffed defatted soybeans and cooked defatted soybeans were studied in the dry weight ratio of 10:0, 8:2, 6:4, 5:5, 4:6, 3:7, 0:10. However, cooked defatted soybeans are expressed by dry weight before cooking. In fact, after adding the lactic acid bacteria culture solution (pH6.3) of L.lactis AJ110212 (FERM BP-8552) in the expanded defatted soybeans and the cooking defatted soybeans of the mixing ratio shown in Table 3, add A.sojaeAJ117552 (FERM P-19637 ) spores, making it a 2×10 6 pieces / g of raw materials. 300 g of the mixture was put into koji respectively, and koji making was carried out for 43 hours while keeping the product temperature at 30-32°C. 540 g of salt w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com