Product package, packaging material and use of the packaging material

A packaging material and product packaging technology, applied in packaging, wrapping paper, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Samples of fiber-based packaging material were tested in an autoclave with saturated steam at a temperature of 130°C. The fibrous base of the material consists of packaging board made of bleached pulp with a weight of 250g / m 2 . Test material 1 also consisted of this material. Test material 2 consisted of said panels with a passing weight of 20 g / m 2 A layer of low-density polyethylene (LDPE) (used as an adhesive) was laminated with aluminum foil on the other side of the board. Test materials 3-11 were layered packaging materials whose substrate consisted of test material 2, in which on the side opposite to the aluminum foil a single layer of polymer coating was provided on the plate. The polymers of this layer are polyethylene (test material 3), polypropylene (test materials 4 and 5), blends of 70% polypropylene and 30% polyethylene (test materials 6 and 7), 92% of the above mentioned polypropylene and polypropylene Colored mixture of ethylene mixture and 8% titani...

Embodiment 2

[0043] According to Example 1, a series of tests were carried out on a material in which the fibrous substrate consisted of packaging board made of bleached pulp with a weight of 210 g / m 2 (Test material 1). On one side of the board, with the aid of a weight of 20g / m 2The LDPE adhesive layer is laminated with aluminum foil (test material 2), while on the other side of the board there are additionally two layers of polymer coating, the inner layer of which contains a mixture of 70% polypropylene and 30% polyethylene, where Various amounts of titanium dioxide were added and the outer layer was pure polypropylene (test materials 3-12). The moisture content of the fibrous substrate and the brightness of the polymer-coated side of the material measured before and after autoclaving are shown in Table 2. Also included in the table are the pigmented inner polymer layer and the unpigmented outer polymer layer, respectively.

[0044] Table 2

[0045]

[0046] The results show tha...

Embodiment 3

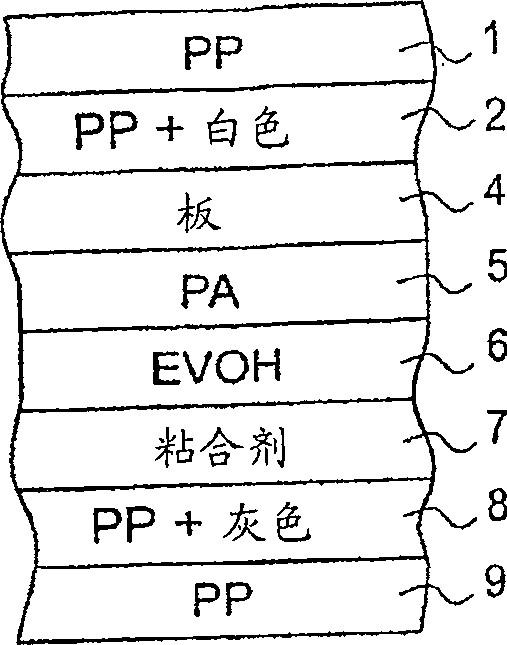

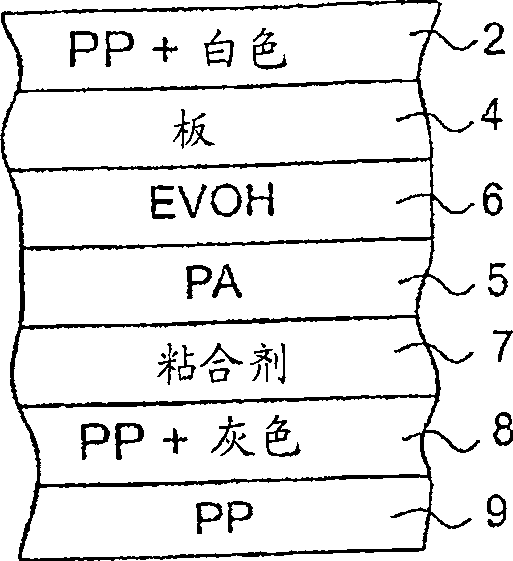

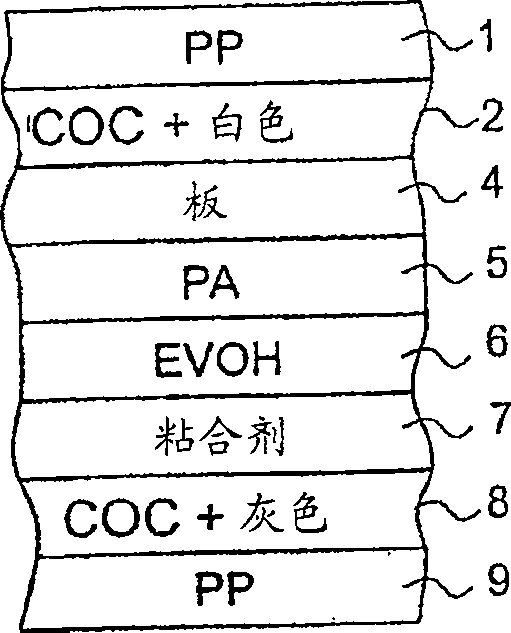

[0048] In this example, a test series was carried out using a test material free of aluminum, the fibrous substrate of which consisted of packaging board made of bleached pulp, weighing 210 g / m 2 (Test material 1). One side of the board is coated with a polymer layer in which 7.5% titanium dioxide is mixed in polypropylene, the layer weight is 58g / m 2 (Test material 2). The other side of the panel is coated with an unpigmented polymer coating (test materials 3-6), or has a layered structure consisting of two or three consecutive unpigmented polymer layers (test materials 7-11) . The materials of the coating are: polypropylene (test materials 3 and 4); a mixture of 70% polypropylene and 30% polyethylene (test materials 5 and 6); a two-layer structure (test material 7), wherein the inner layer is COC (Topas 8007D), the outer layer is the blend of polypropylene and polyethylene; three-layer structure (test materials 8 and 9), its innermost layer is polyamide, followed by adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com