Channel-type clutch

A technology of clutches and slots, which is applied in the field of clutches, can solve problems such as high requirements for molds and tooling equipment, low requirements for steel ductility, and high requirements for steel ductility, so that the production process conditions are easy to grasp, product quality is easy to control, and tooling The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

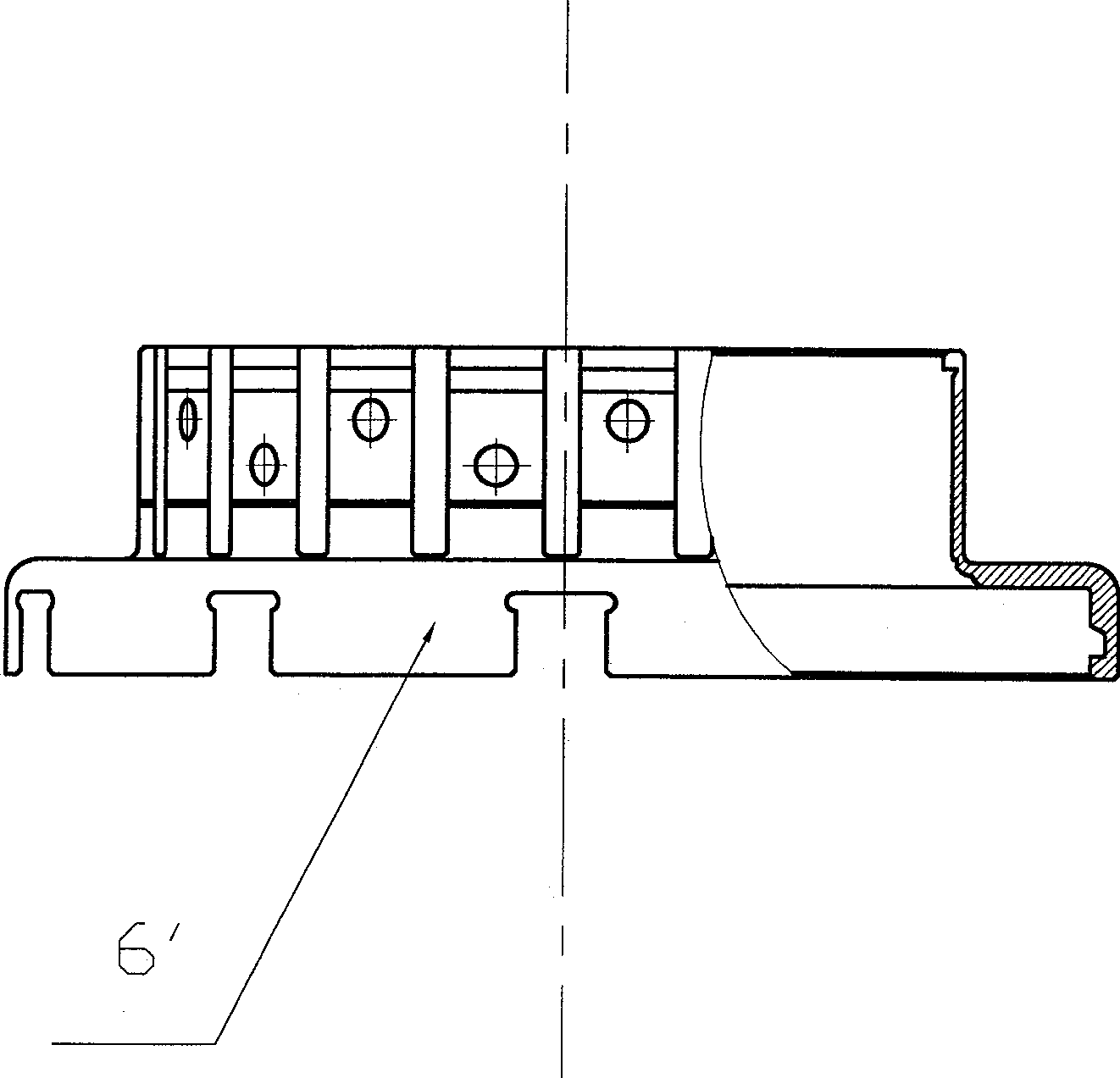

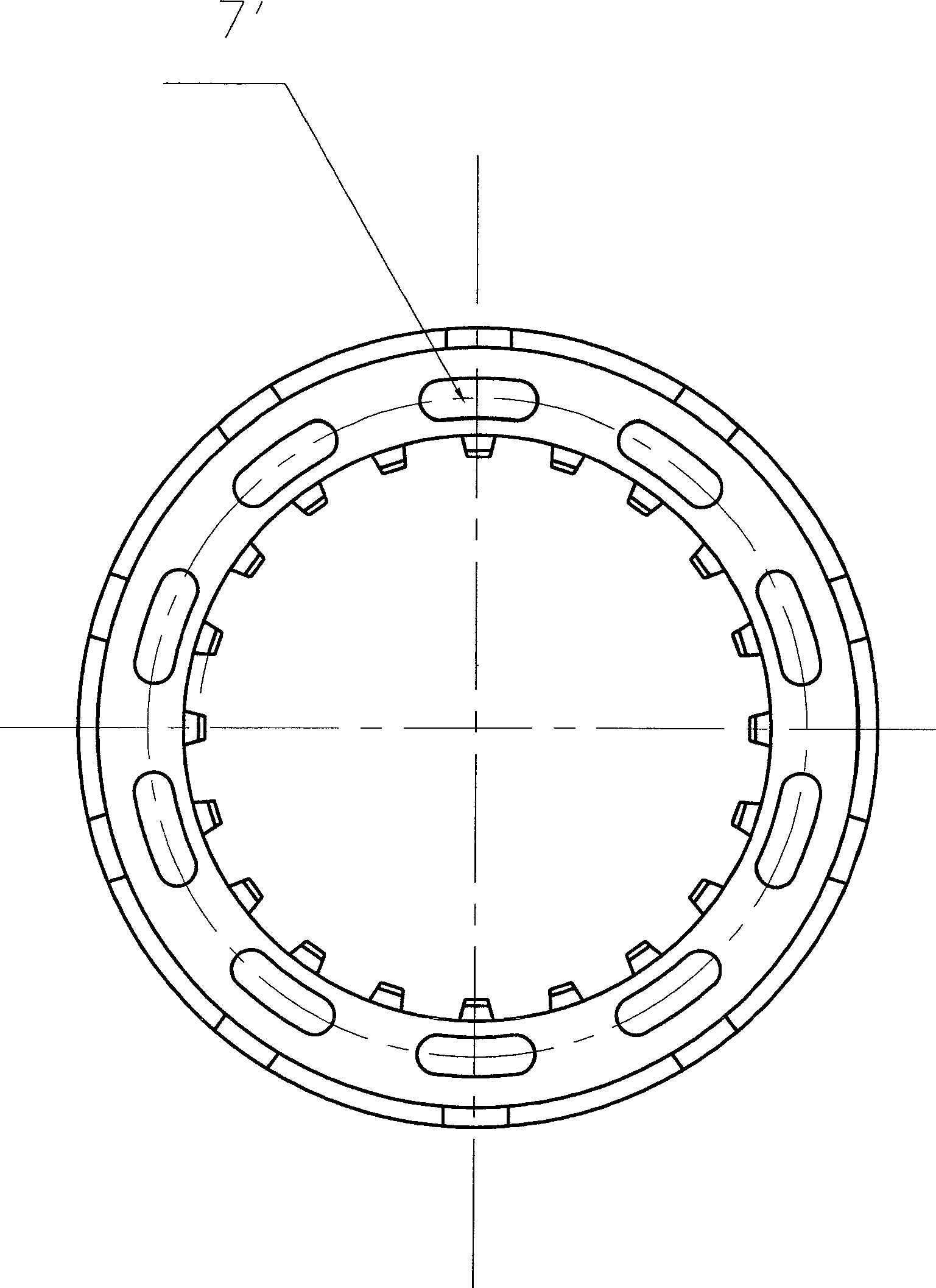

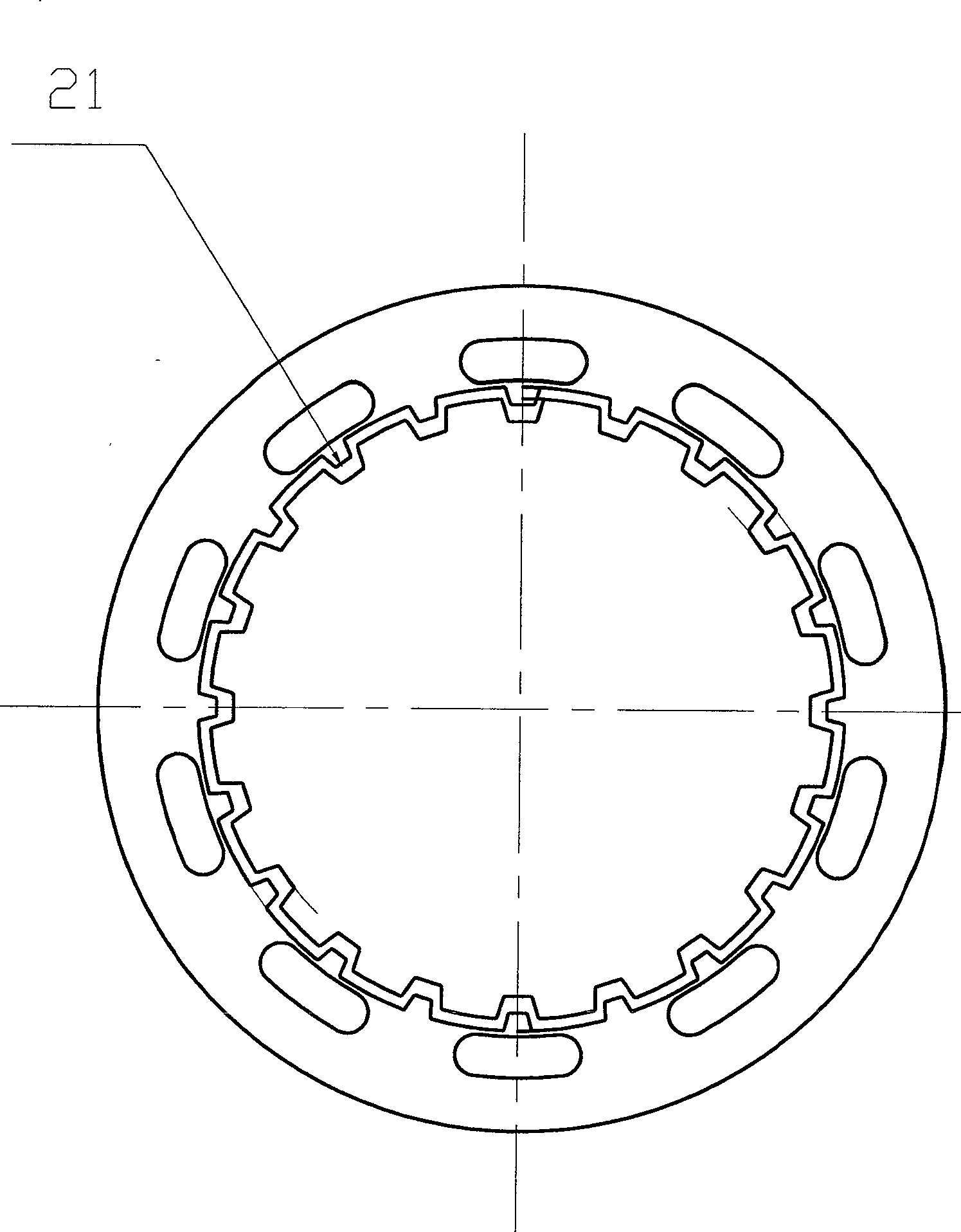

[0024] Embodiment 1: The through-groove clutch is mainly composed of three parts: a transmission shaft 15 , a clutch body 16 and a transition sleeve 17 . One end of the transmission shaft 15 is provided with a clutch body 16 , and the clutch body 16 is provided with a transition sleeve 17 . The transition sleeve system is composed of several force transmission columns 3 on the transition plate body 6, and through grooves 2 are arranged between each force transmission column 3. The outer convex teeth of the inner friction body 10 and the inner convex teeth of the outer friction body 11 are both The card is placed in the through groove, there is a gap between the two convex teeth, and they are not in contact with each other. The friction body is composed of multiple friction rings and steel rings superimposed on each other according to the principle of stacking steel plates on friction rings and then stacking friction rings and steel plates. Composed of forms, the top is still a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com