Caliper for a disk brake

A technology of disc brakes and brake calipers, which is applied in the direction of brake actuators, bearings for rotational motion, slack adjusters, etc., can solve the problems of large component stress, impracticality, and high cost of rolling bearings in the adjustment device, and achieve simplified assembly, Avoid stress concentrations, effects of low load levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

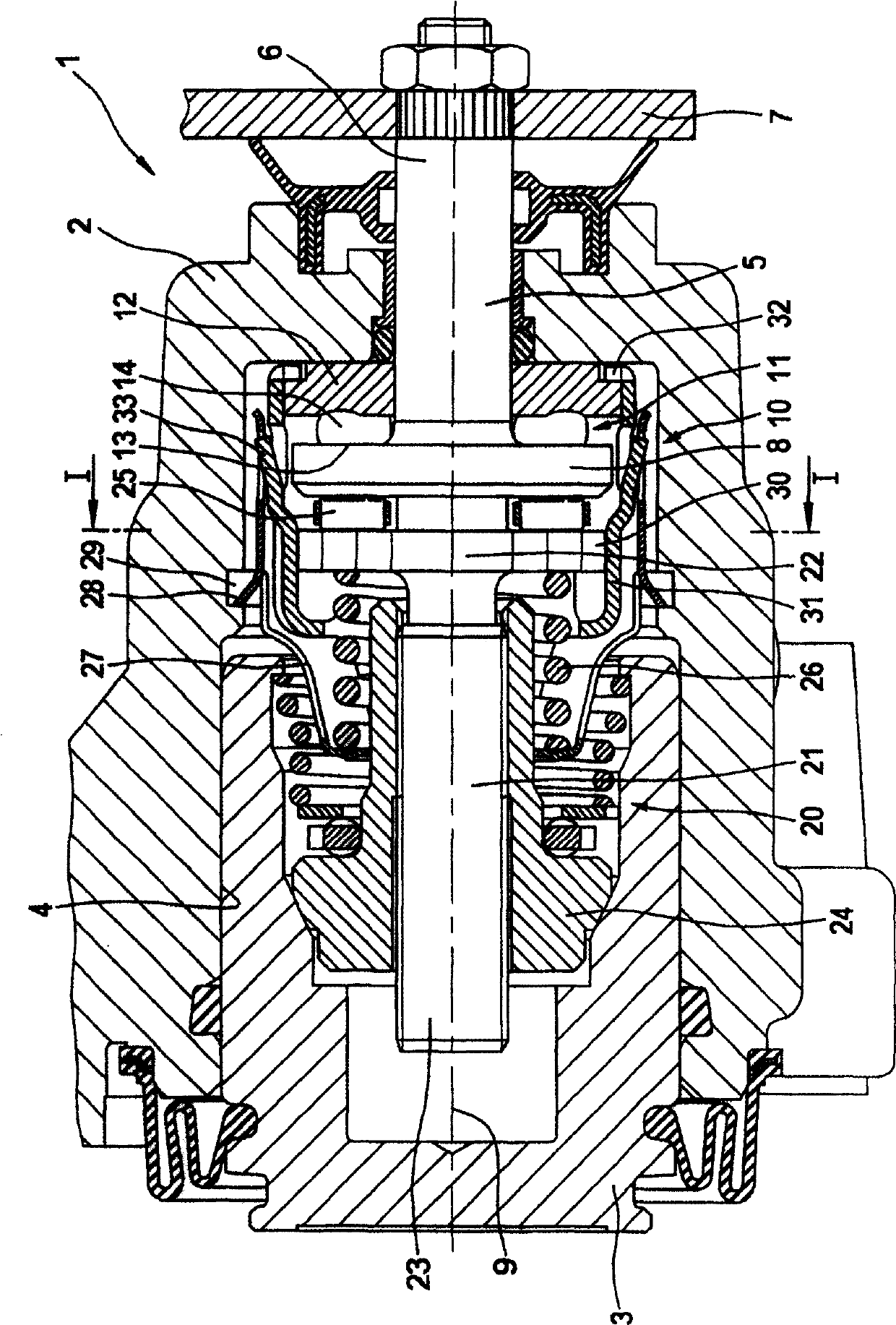

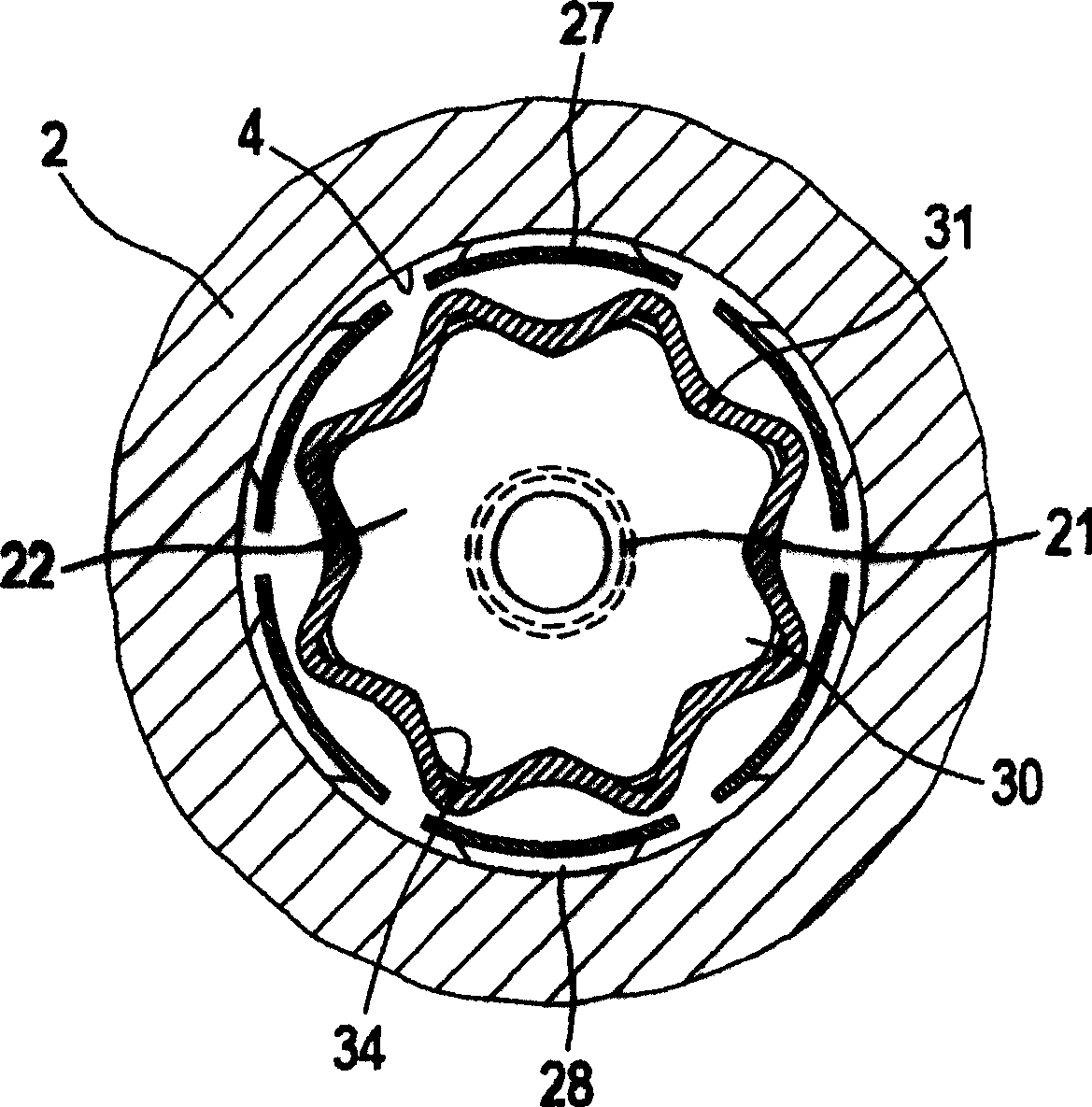

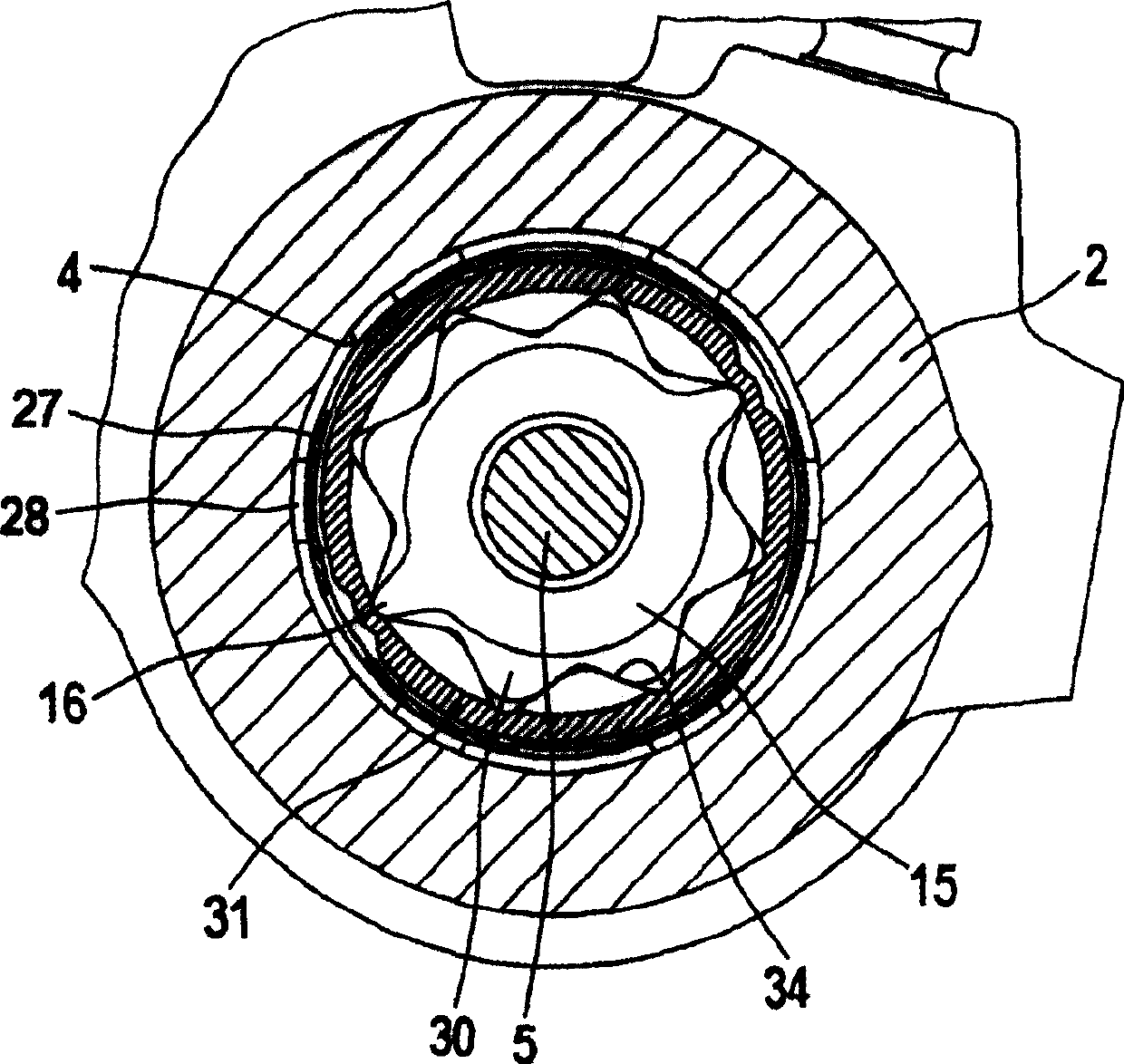

[0029] exist figure 1 The caliper 1 of a disc brake for a motor vehicle shown in , in particular comprises a housing 2 and a piston 3 which is movably arranged in a bore 4 for braking operation. In the case of a normal braking operation, the piston 3 is hydraulically movable. In order to realize the parking brake, a shaft 5 is provided which allows the piston 3 to be moved in the bore 4 by means of the actuating device 10 . The shaft 5 extends through an opening in the housing 2 with a shaft end 6 on which an actuating lever 7 is mounted. The actuating device 10 acts on the piston 3 by interposing an adjustment device 20 of variable length.

[0030] The actuating device 10 comprises a ramp structure 11 having a ramp element 12 fixed on said housing and a ramp element 13 rotatable relative to the ramp element 12 . The ramp element 13 is now integrally formed on the disk-shaped end 8 of the shaft 5 . A plurality of rolling bodies 14 are arranged between the ramp elements 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com