A multi-channel membrane tube and application thereof

A multi-channel, membrane tube technology, applied in the field of multi-channel membrane tubes, can solve the problems of restricting the distribution ratio of permeate, increasing the complexity of membrane components and manufacturing costs, and achieving the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

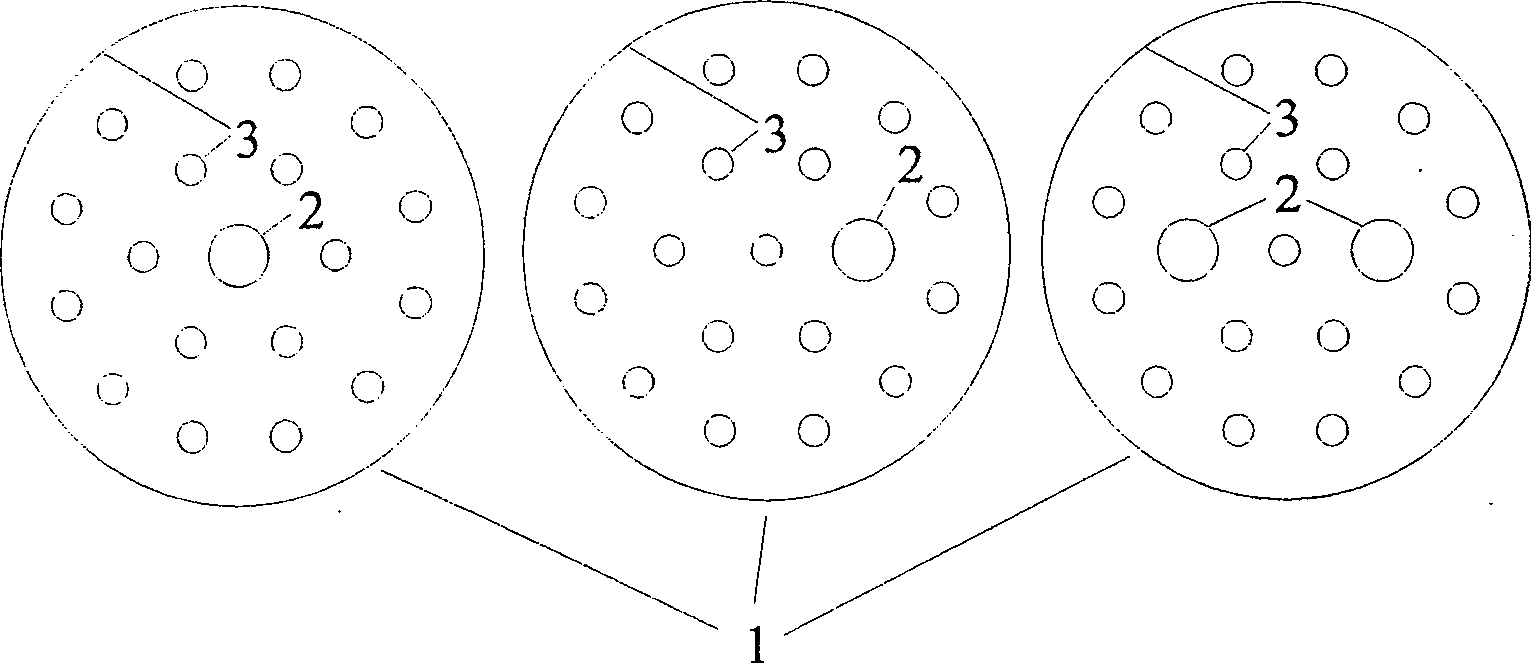

[0032] The end face of the multi-channel membrane tube is as figure 1 shown. Membrane tube support adopts AL 2 o 3 The ceramic material is extruded at one time, the length is 0.5m, the diameter of the membrane tube is 41mm, there are 18 raw material side channels, 1 permeation side channel, the diameter of the raw material side channel is 6mm, and the wall thickness between channels is 2mm. The permeate side channel is located in the middle of the membrane tube, one end is closed, the plugging length is 1cm, and the other end is sintered with a 2.5cm long section of enamel as the inner socket, which is inserted into the inner plug pipeline with O-ring to lead out the permeate. The outer surface and both ends of the membrane tube are sealed with sintered enamel, the raw material side channel is covered with an aluminum oxide film layer with an average pore diameter of 0.2 μm, and the porosity of the support body and the film layer is 35%. Immerse the membrane tube in the flu...

Embodiment 2

[0034] The end face of the multi-channel membrane tube is as figure 1 shown. Membrane tube support adopts AL 2 o 3 The ceramic material is extruded at one time, the length is 0.5m, the diameter of the membrane tube is 31mm, there are 6 raw material side channels, 1 permeation side channel, the diameter of the raw material side channel is 6mm, and the wall thickness between the channels is 2mm. The permeate side channel is evenly distributed in the middle of the membrane tube, one end is closed, the plugging length is 1cm, and the other end is sintered with a 2.5cm long section of enamel as the inner socket, which is inserted into the inner plug pipeline with O-ring to lead out the permeate. The outer surface of the membrane tube, both end surfaces and the raw material side channel are covered with a layer of titanium oxide film layer with an average pore diameter of 0.05 μm, and the porosity of the support body and the film layer is 35%. The total membrane surface area on t...

Embodiment 3

[0036] The end face of the multi-channel membrane tube is as figure 1 shown. The membrane tube support is extruded from alumina powder, the length is 0.5m, the diameter of the membrane tube is 31mm, there are 6 raw material side channels, 1 permeation side channel, the channel diameter is 6mm, and the wall thickness between channels is 2mm. The permeate side channel is evenly distributed in the middle of the membrane tube, and both ends are coated with a 1.5cm long section of epoxy resin adhesive to seal the external joint, and then the external pipeline is connected to lead out the permeate. The outer surface of the membrane tube, both end surfaces and the raw material side channel are covered with a zirconia membrane layer with an average pore diameter of 0.05 μm, and the porosity of the support body and the membrane layer is 35%. Immerse the membrane tube in the flux detection cell, air-lift cross-flow, the feed liquid is 1g / L alumina particle suspension with a particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com