Process for catalytic cracking of petroleum hydrocarbon

A technology of catalytic cracking and petroleum hydrocarbons, which is applied in the direction of catalytic cracking, cracking, petroleum industry, etc., to achieve the effect of realizing contact, reducing elevation and improving contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment illustrates: adopt the implementation effect of the method provided by the present invention.

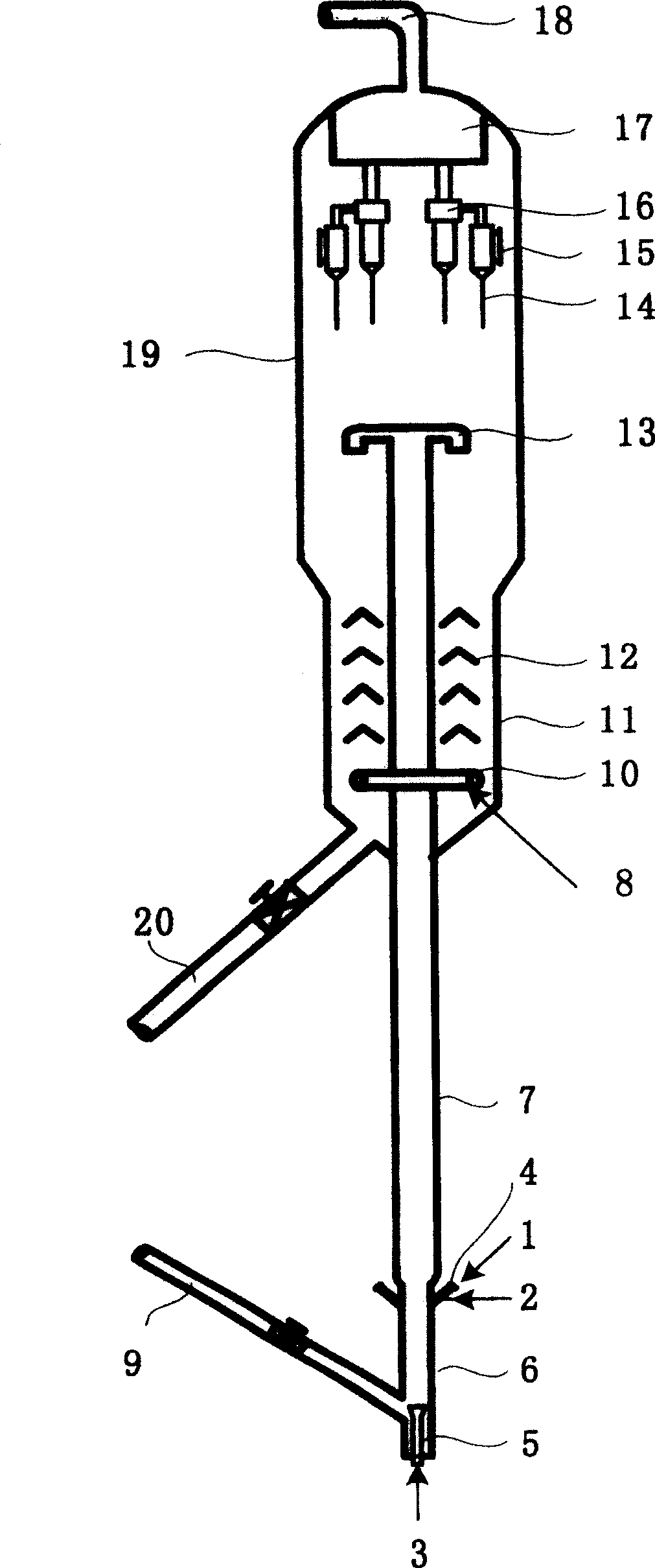

[0028] in such as figure 1 Experiments were carried out on the catalytic cracking medium-sized unit shown. The main test steps are as follows: pre-lift steam is injected from the bottom of the riser reactor, and raw material A (its properties are shown in Table 1) is injected into the riser reactor through nozzle 4. The angle formed by the central axis of the nozzle 4 and the central axis of the riser reactor is 135°. The raw oil contacts and reacts with the regenerated catalyst MLC-500 (its properties are shown in Table 2), and the generated oil gas and the reacted catalyst enter the settler upward; the reaction oil gas and the reacted catalyst are separated, and the reaction oil gas is sent to the subsequent The separation system is further separated into various products; the reacted catalyst is stripped and then sent to the regenerator for coke regenerat...

Embodiment 2

[0032] This embodiment illustrates: adopt the implementation effect of the method provided by the present invention.

[0033] in such as figure 1 Experiments were carried out on the catalytic cracking medium-sized unit shown. The main test steps are as follows: pre-lift steam is injected from the bottom of the riser reactor, and raw material A (its properties are shown in Table 1) is injected into the riser reactor through nozzle 4. The angle formed by the central axis of the nozzle 4 and the central axis of the riser reactor is 155°. The raw oil contacts and reacts with the regenerated catalyst MLC-500 (its properties are shown in Table 2), and the generated oil gas and the reacted catalyst enter the settler upward; the reaction oil gas and the reacted catalyst are separated, and the reaction oil gas is sent to the subsequent The separation system is further separated into various products; the reacted catalyst is stripped and then sent to the regenerator for coke regenerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com