Heat-proof wall, heater keeper tectosome, heating arrangement and substrate processing unit

A technology for a substrate processing device and a heating device, which can be used in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., and can solve problems such as heating element breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

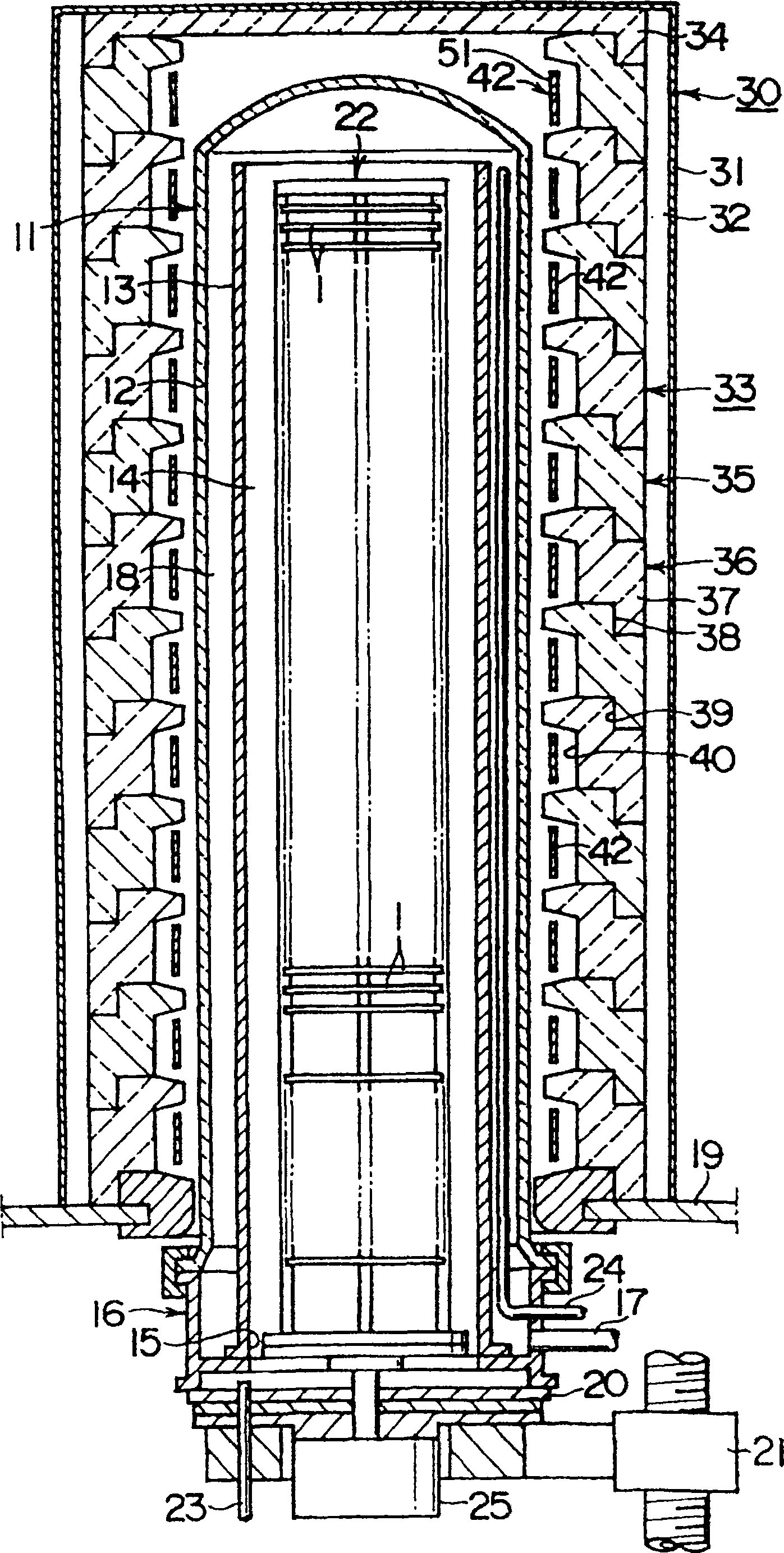

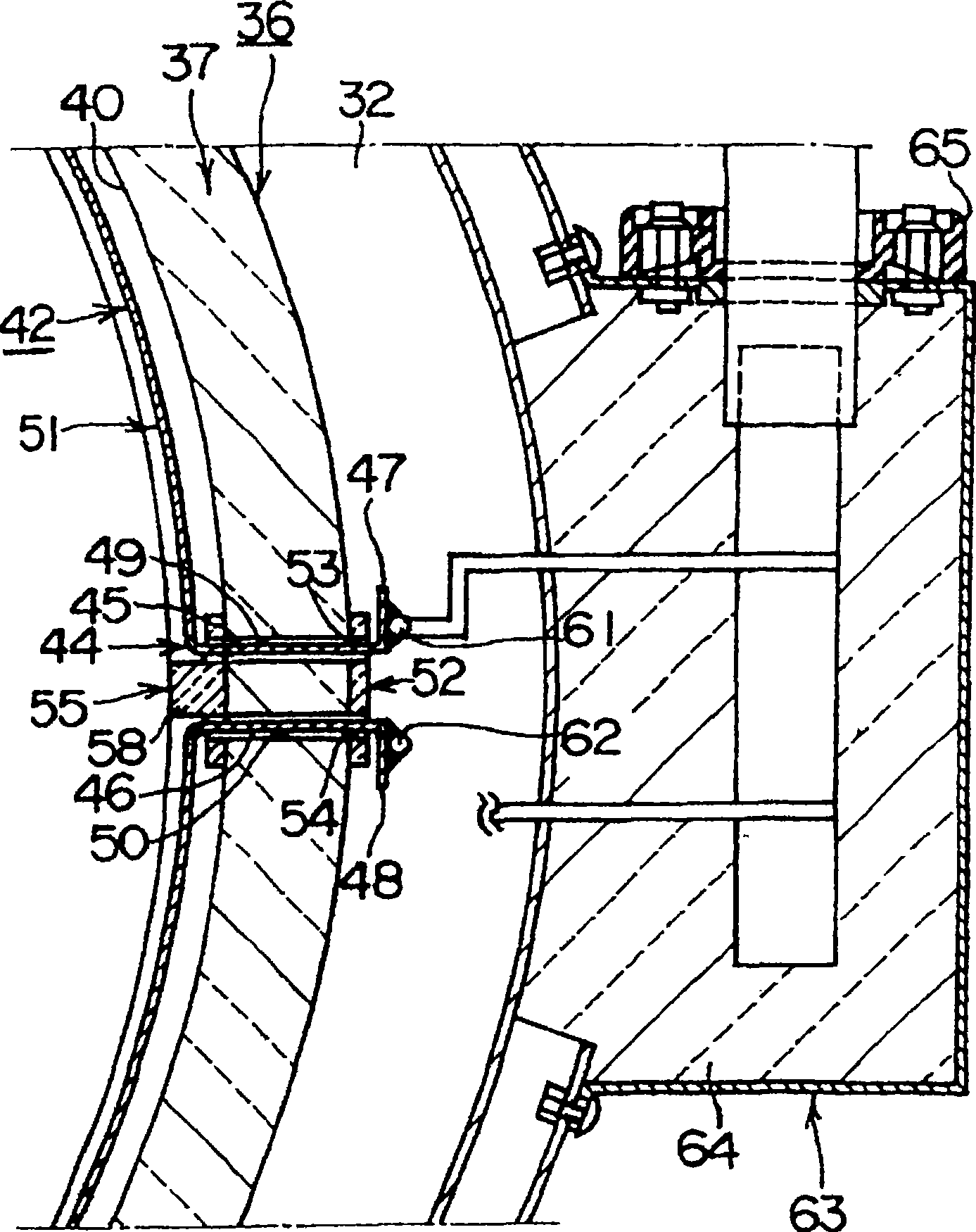

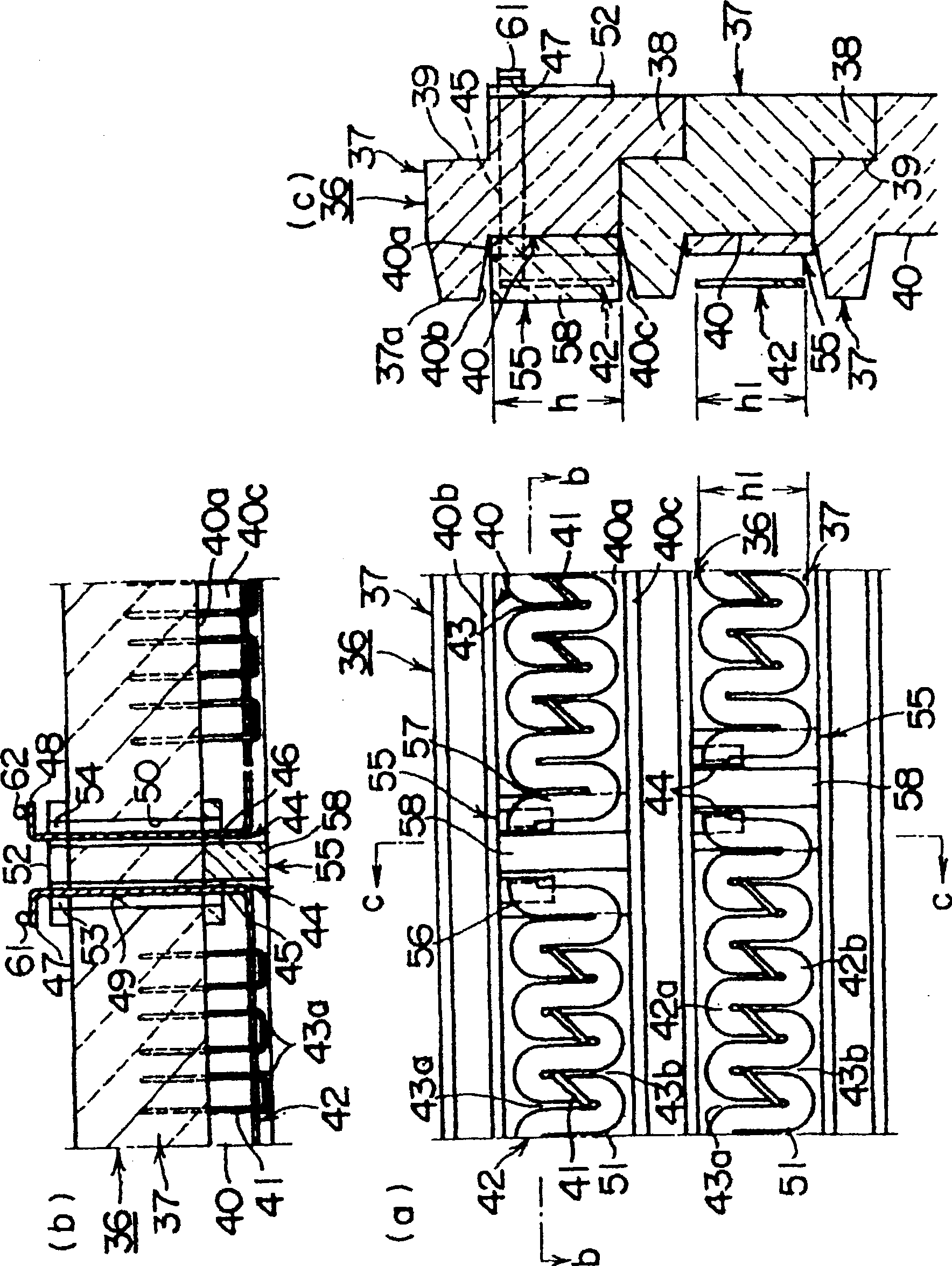

[0052] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0053] In this embodiment, the heat insulating wall body according to the present invention is installed in a CVD apparatus (batch-type vertical hot-wall diffusion CVD apparatus) which is one embodiment of the substrate processing apparatus according to the present invention. The heater unit of one embodiment of the heating device is used.

[0054] As one embodiment of the substrate processing apparatus of the present invention, a CVD apparatus such as figure 1 As shown, there is provided an upright reaction tube 11 arranged vertically and fixedly supported, and the reaction tube 11 includes an outer tube 12 and an inner tube 13 .

[0055]Outer tube 12 uses quartz (SiO 2 ) and integrally formed into a cylindrical shape, the inner tube 13 uses quartz (SiO 2 ) or silicon carbide (SiC) integrally formed into a cylindrical shape.

[0056] The outer tube 12 is formed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com