Stereo-low-level vacuum prepressing soft foundation processing method

A processing method and three-dimensional technology, which can be applied in the field of intermediary, can solve the problems of unreasonable economy, long construction period and high construction cost, and achieve the effects of broad application prospects, good economic benefits and short processing period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

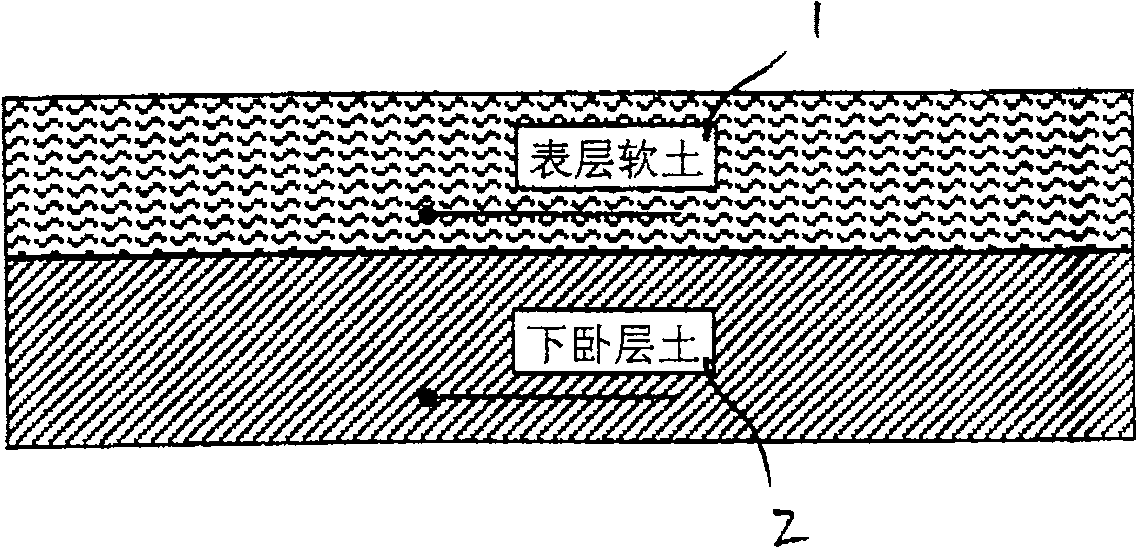

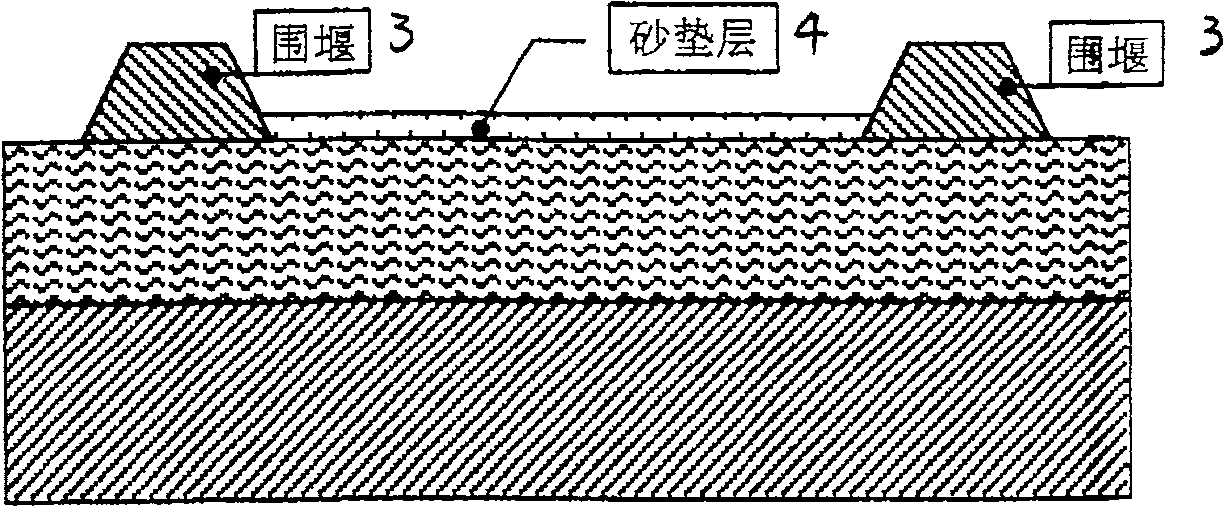

[0019] figure 1 , 2 , 3, 4, 5, 6, and 7: 1 is surface soft soil; 2 is underlying soil; 3 is cofferdam; 4 is sand cushion; 5 is vacuum tube; 6 is preset horizontal drainage channel; 7 is The preset horizontal main pipe; 8 is the reserved interface; 9 is the dredging and filling; 10 is the vacuum pump.

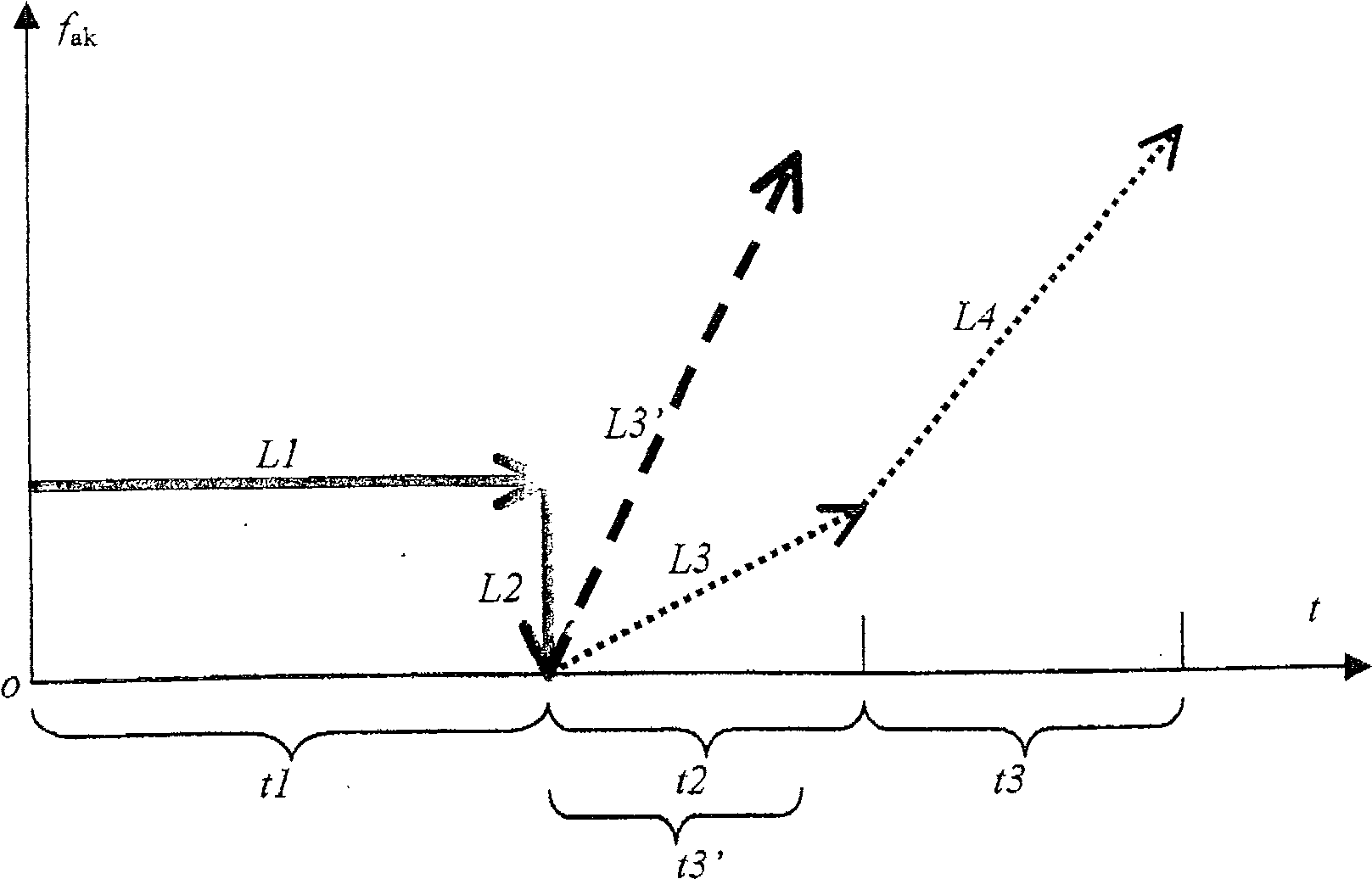

[0020] figure 1 is the difference in ground treatment time between the three-dimensional low-level vacuum composite preloading method and the conventional treatment method, where the abscissa is time, the ordinate is the bearing capacity of the foundation, t1 is the time used for dredging and filling, and t2 is the conventional self-weight consolidation time, t3 is the time required for conventional foundation treatment; t3' is the time required for three-dimensional low-level vacuum composite preloading method. The broken line L1+L2+L3+L4 is the conventional treatment process, and the corresponding time is t1+t2+t3; the broken line L1+L2+L3' is the three-dimensional low-leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com