Suspended carriage for wind energy facility, rotary connecting device for wind egergy facility, wind egergy facility, driving method for wind egergy facility

A rotary connector and wind energy technology, which is applied in the direction of wind power generators, wind power generation, and wind power engines in the same direction as the wind, can solve the problems of loss, wind energy facility downtime, large size, etc., and achieve the effect of easy monitoring and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

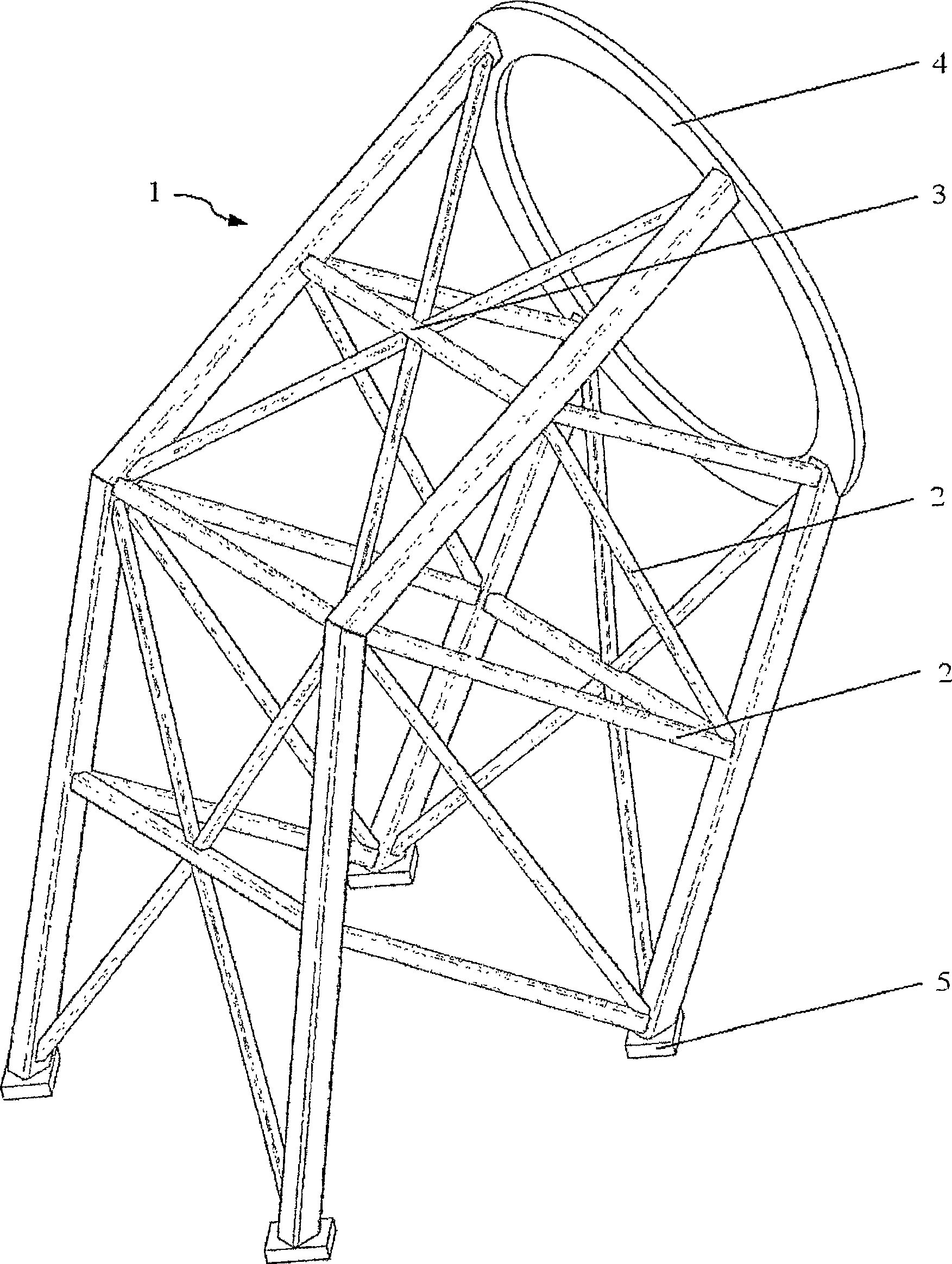

[0056] figure 1 An isometric view of the truss structure of a car 1 of the present invention is given. The truss structure consists of rods 2 which form nodes 3 at intersections. Its closing end is formed by a ring 4 in the direction of the rotor sleeve, not shown in the figure. On the side facing away from the ring 4 , the vertical load is distributed via the car-side coupling point 5 . The advantage of the truss member is: due to its versatility, it can provide a very wide variety of possible ways for the car 1 of the present invention, and can be stacked without any problem (unlike the "fishing technique" in toys of the prior art). "Contrast) for expansion.

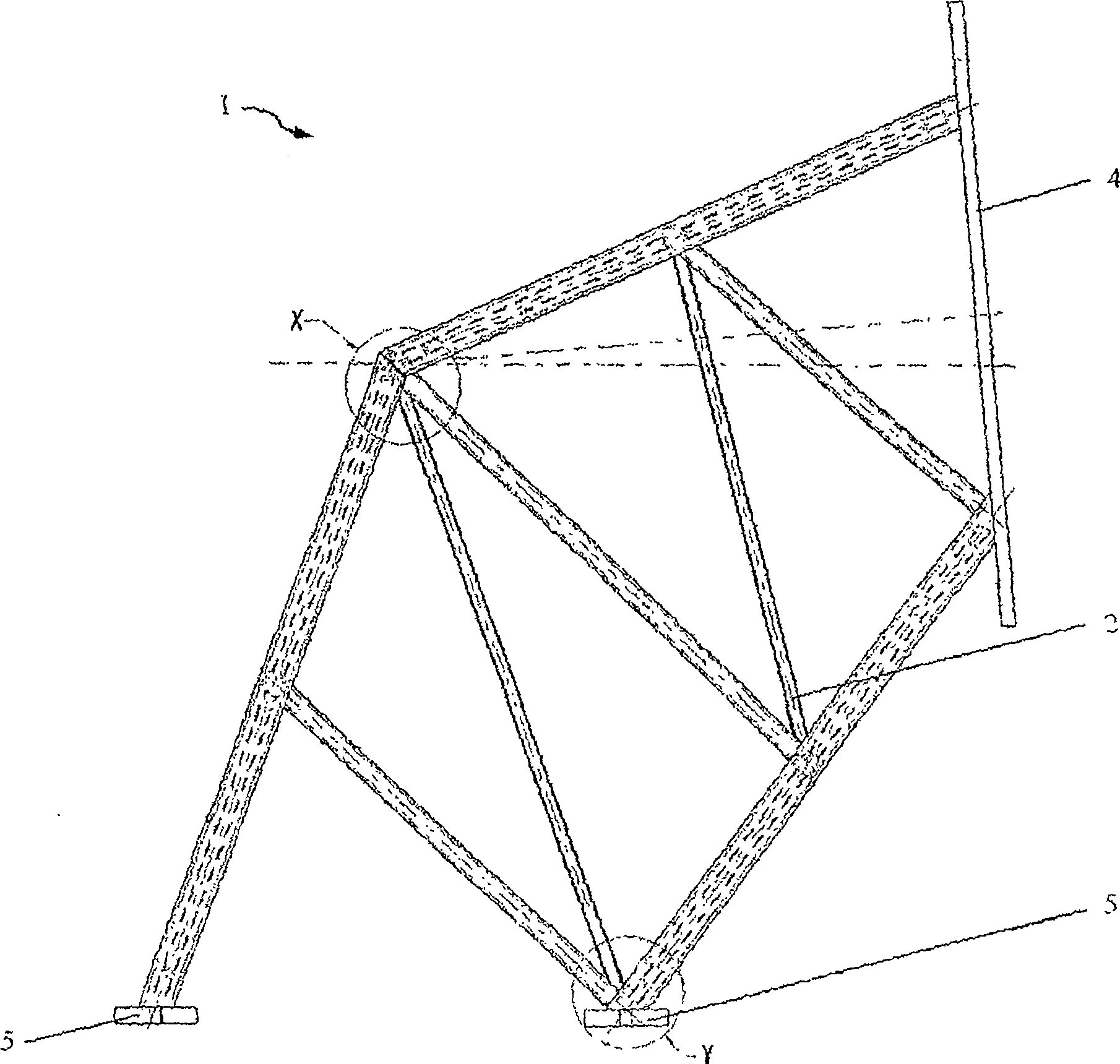

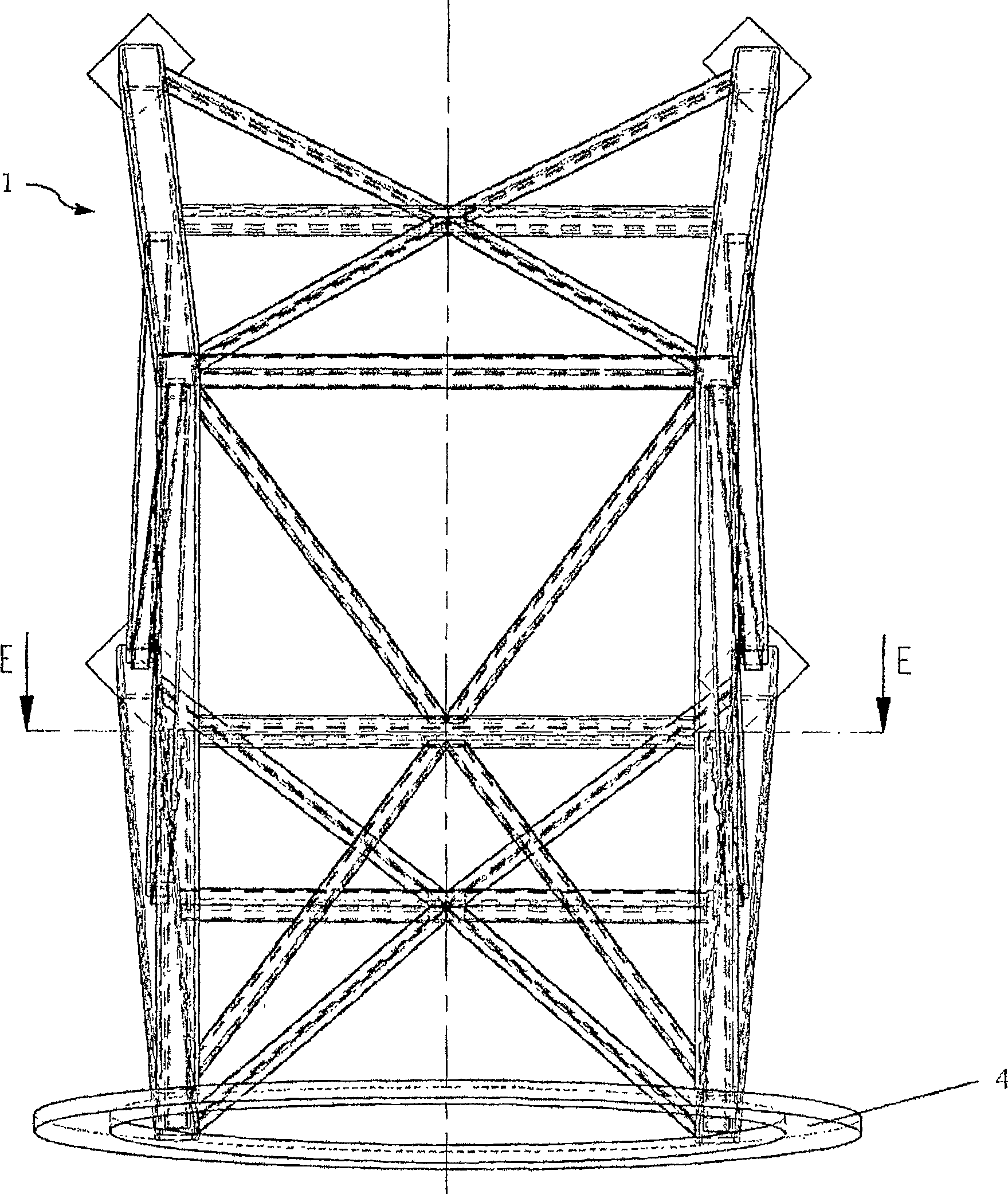

[0057] figure 2 and image 3 The front view and top view of the truss structure of the car 1 of the present invention are given in . It is obvious that the ring 4 does not have to be vertically oriented, but can also be arranged somewhat obliquely (inclined with respect to the rotor). A detailed view in X and Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com