Method and apparatus for rapid heating of fuel reforming reactants

一种快速加热、燃料重整器的技术,应用在燃烧方法、照明和加热设备、化学仪器和方法等方向,能够解决难储存和运输、缺少氢气基础结构、氢气低体积效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Exemplary embodiments of the present invention are described below. In the interest of clarity, not all features of an actual implementation are described in this specification. Of course, it should be understood that in the development of any such practical implementation, many device-specific decisions must be made to achieve the developer's specific goals, as consistent with system-related and business-related constraints that can be derived from a device to another device may differ from each other. Moreover, it is to be understood that such a development effort, possibly complex and time consuming, would be the route taken by those skilled in the art having the benefit of this disclosure.

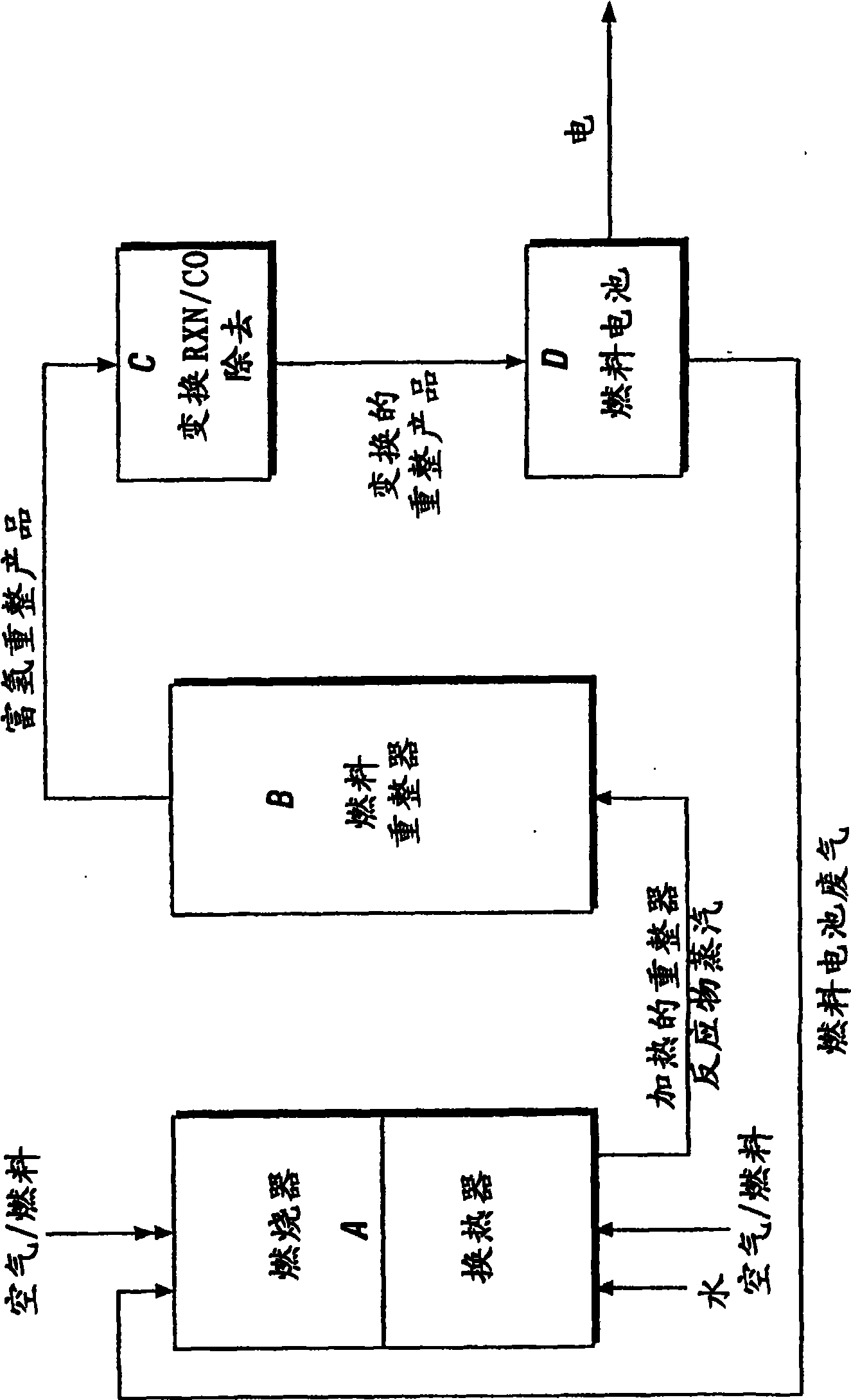

[0015] figure 1 is a block diagram of the pre-reformer A integrated with the fuel reformer B used in supplying the hydrogen-rich reformate to the fuel cell stack D as fuel. figure 1 is highly simplified and is intended to illustrate the manner in which these systems may be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com