On-line detection method for transformer insulation oil temperature and characteristic gas in oil and oil chromatography

A technology of transformer insulating oil and characteristic gas, which is applied to thermometers, thermometers with directly heat-sensitive electric/magnetic elements, instruments, etc., and can solve problems such as poor data accuracy, inaccurate transformer fault analysis, and safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

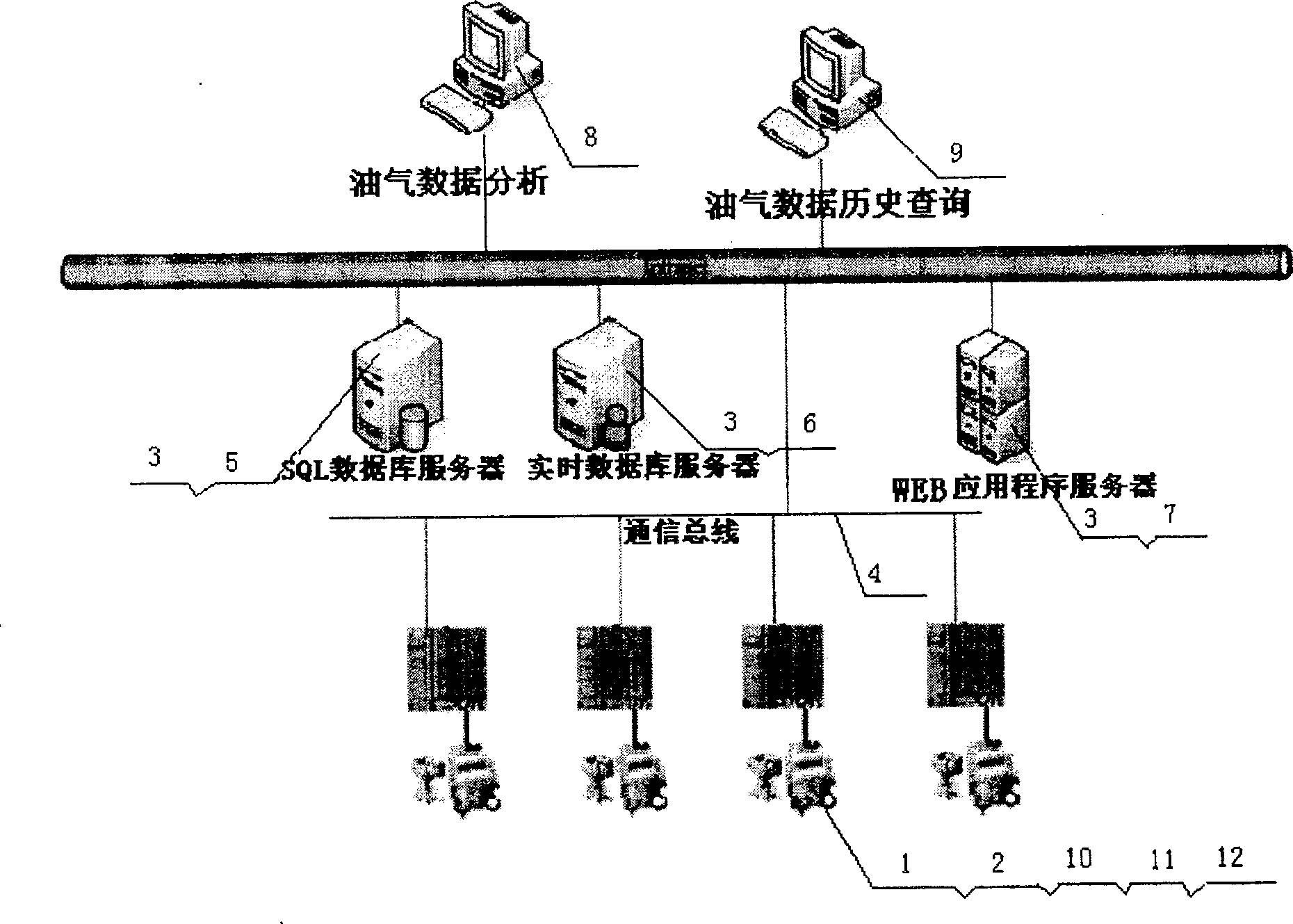

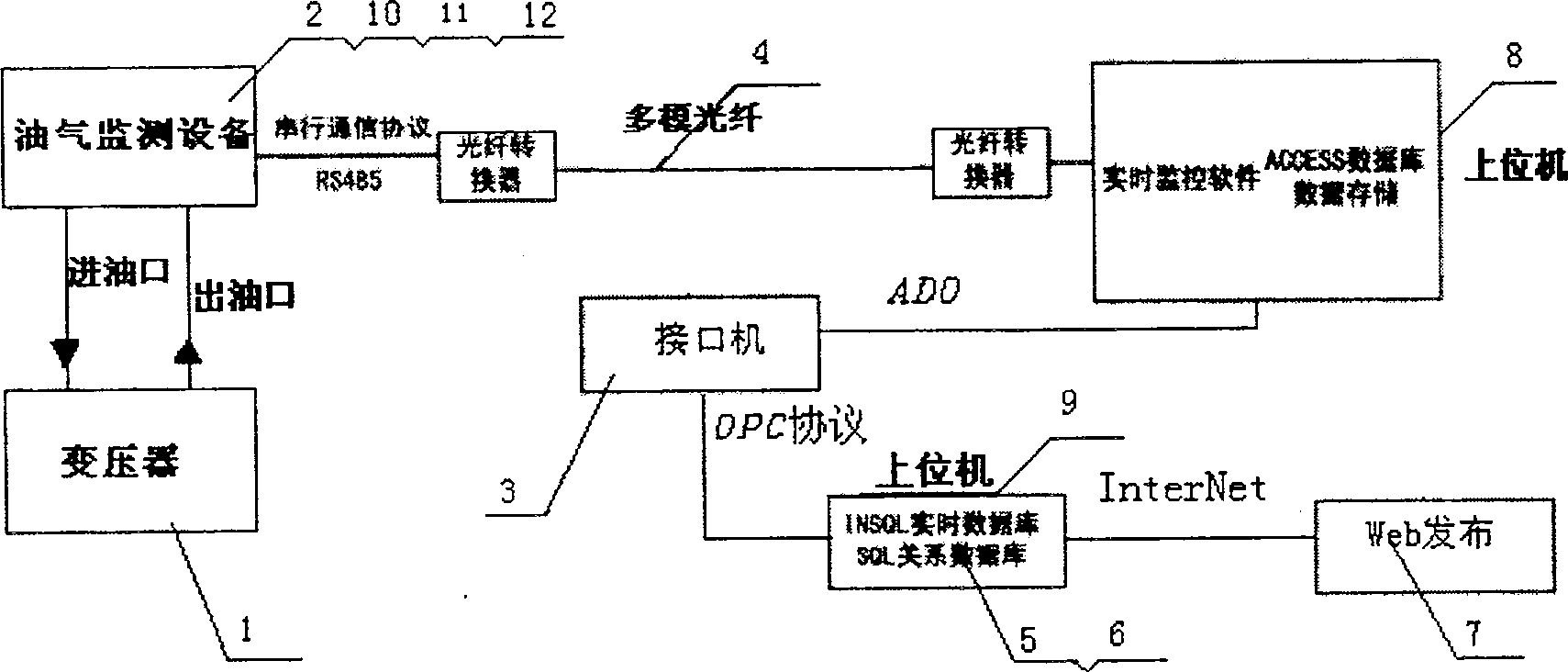

[0027]There are four sets of transformers 1 in the power supply system of the electrolytic aluminum enterprise, and the oil circuits of each set of high-voltage transformers and rectifier transformers are connected. The system is equipped with 4 temperature control instruments 10 to detect the insulating oil temperature of 4 sets of transformers 1; the system is equipped with 2 oil and gas analyzers 11, and each oil and gas analyzer 11 can detect the characteristic gas in the insulating oil of two transformers 1; the system Two test controllers 12 are configured to analyze and detect the oil and gas components of transformers 1 in groups 1 and 2 and groups 3 and 4 respectively. At the same time, 2 sets of oil circuit switching devices are configured to realize the detection and switching function of the 1st and 2nd group of transformers. In the selection of the sampling oil circuit, the solenoid valve is used to automatically control the selection of the oil circuit.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com