Circle display drive method of shadow mask type plasma display panel

A plasma and display driving technology, which is applied to static indicators, instruments, identification devices, etc., can solve the problems of low efficiency, low brightness, and high maintenance voltage of opposite discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

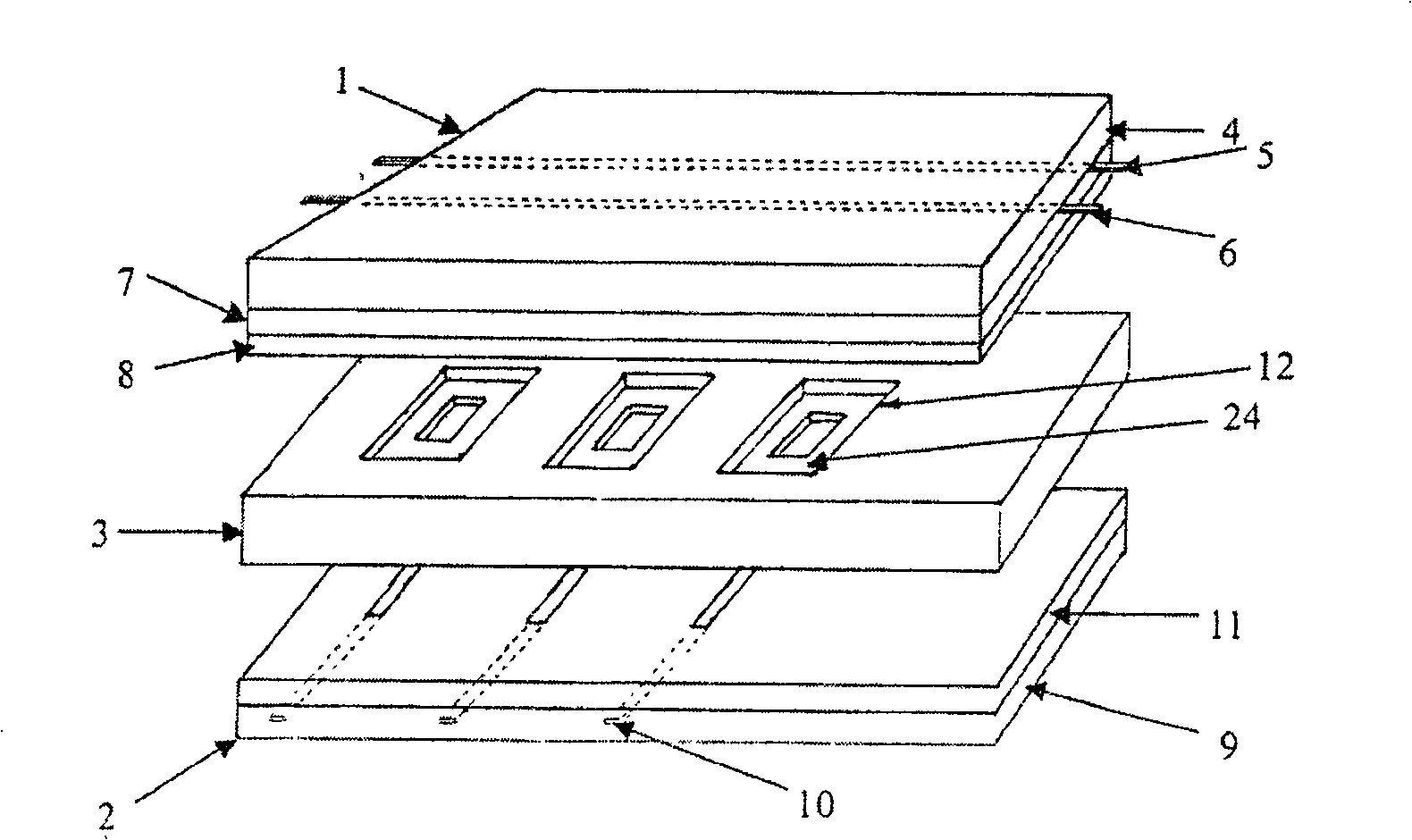

[0020] Such as figure 1 , 3 shown.

[0021] figure 1 It is a three-electrode shadow mask type plasma display panel, which includes a front substrate 1, a rear substrate 2, and a shadow mask 3, wherein the shadow mask 3 is packaged between the front and rear substrates 1 and 2, and the front substrate 1 is mainly composed of the front substrate 1 and the shadow mask 3. Substrate glass substrate 4, first electrode pair 5, 6, dielectric layer 7, protective film 8, wherein the first electrode pair 5, 6 is arranged in parallel on the front substrate glass substrate 4, it can be no transparent conductive film ITO The electrode 5 is called a sustain electrode, the electrode 6 is called a scan electrode, the dielectric layer 7 is covered on the first electrode pair 5, 6, and the protective film 8 is covered on the dielectric layer 7; the rear substrate 2 is mainly It consists of a rear substrate glass substrate 9, a second electrode 10, and a dielectric layer 11, wherein the second...

example 2

[0026] Such as figure 1 , 4 shown.

[0027] Such as figure 1 The three-electrode shadow mask plasma display panel shown includes a front substrate 1, a rear substrate 2, and a shadow mask 3, wherein the shadow mask 3 is packaged between the front and rear substrates 1 and 2, and the front substrate 1 is mainly composed of the front substrate Glass substrate 4, first electrode pairs 5, 6, dielectric layer 7, protective film 8, wherein the first electrode pairs 5, 6 are arranged in parallel on the front substrate glass substrate 4, it can be formed without transparent conductive film ITO electrode, electrode 5 is called sustain electrode, electrode 6 is called scan electrode, dielectric layer 7 is covered on the first electrode pair 5, 6, and protective film 8 is covered on the dielectric layer 7; Substrate glass substrate 9, second electrode 10, dielectric layer 11, wherein the second electrode 10 is located on the rear substrate glass substrate 9, the dielectric layer 11 co...

example 3

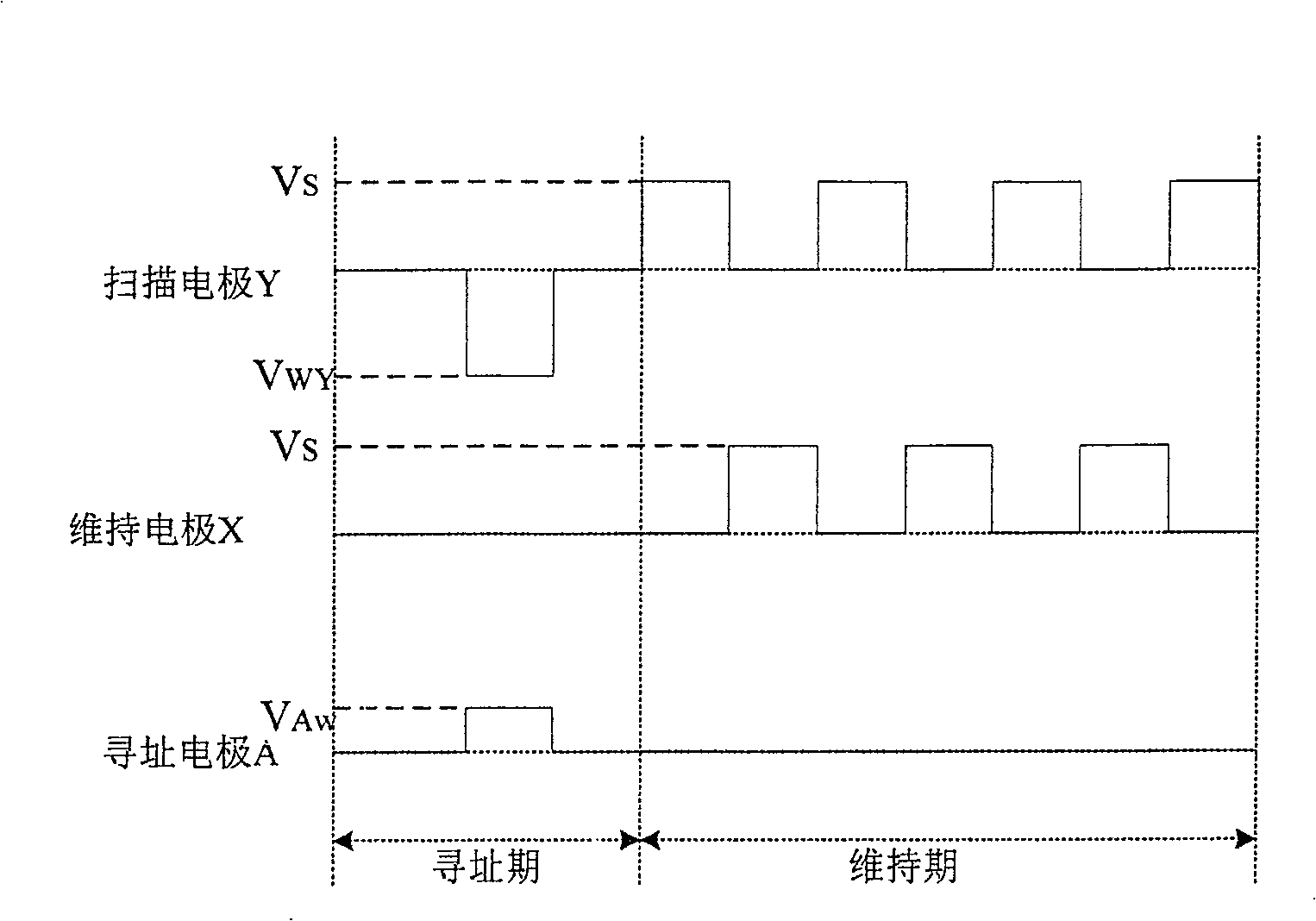

[0030] Such as figure 1 , 5 shown.

[0031] Apply such as Figure 5 As shown in the drive waveform, the shadow mask is applied with a floating potential. During the addressing period, the scan electrodes apply a negative voltage pulse V wy , the sustain electrode applies a negative voltage pulse V wx , the addressing electrode applies a positive voltage pulse V a , generate addressing discharge between scan electrode and address electrode, sustain electrode and address electrode, the dielectric layer near the scan electrode and the dielectric layer near the sustain electrode in the discharge space have accumulated positive wall charges, near the address electrode Negative wall charges are accumulated on the dielectric layer, and the wall voltage formed by the wall charges prepares for the sustain discharge in the sustain period. In the maintenance period, each maintenance period is composed of three phases P1, P2, and P3. The voltage pulse width of the P1 phase is t1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com