High-pressure spray type underwater wire-cloth washing machine

A high-pressure jet and high-pressure technology, which is applied in the field of screen washing machines, can solve problems such as long operation time, poor personal safety, and difficult operation of changing screens, and achieve the effects of saving time and labor, high safety and usability, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

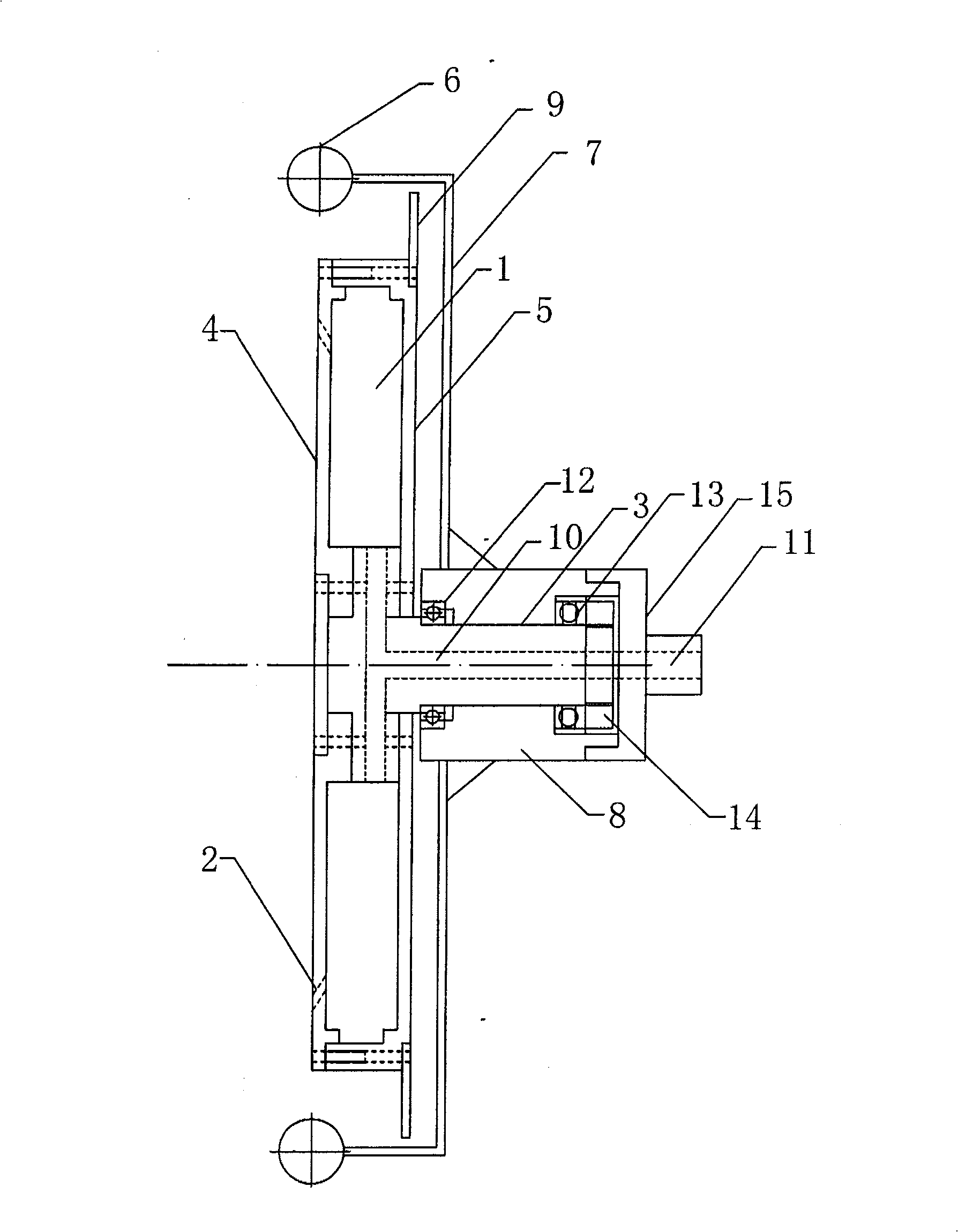

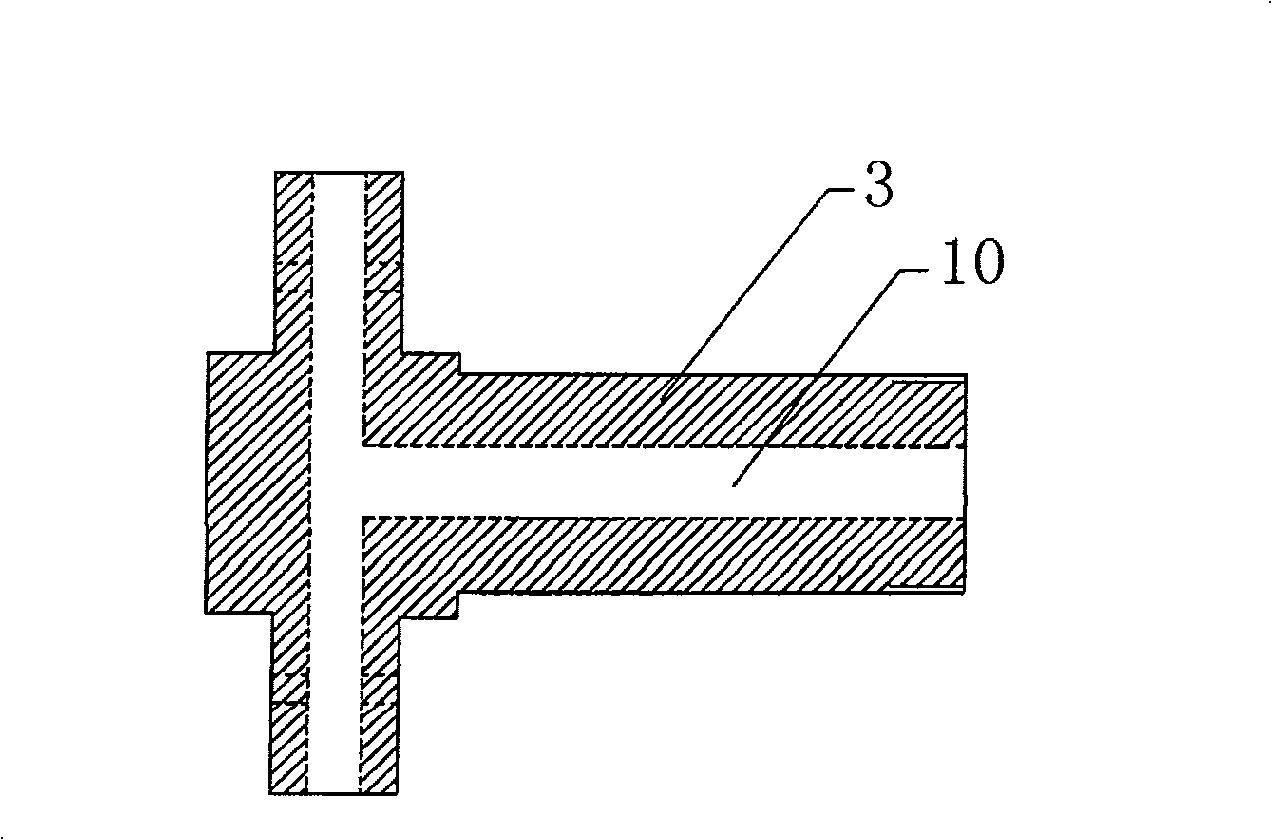

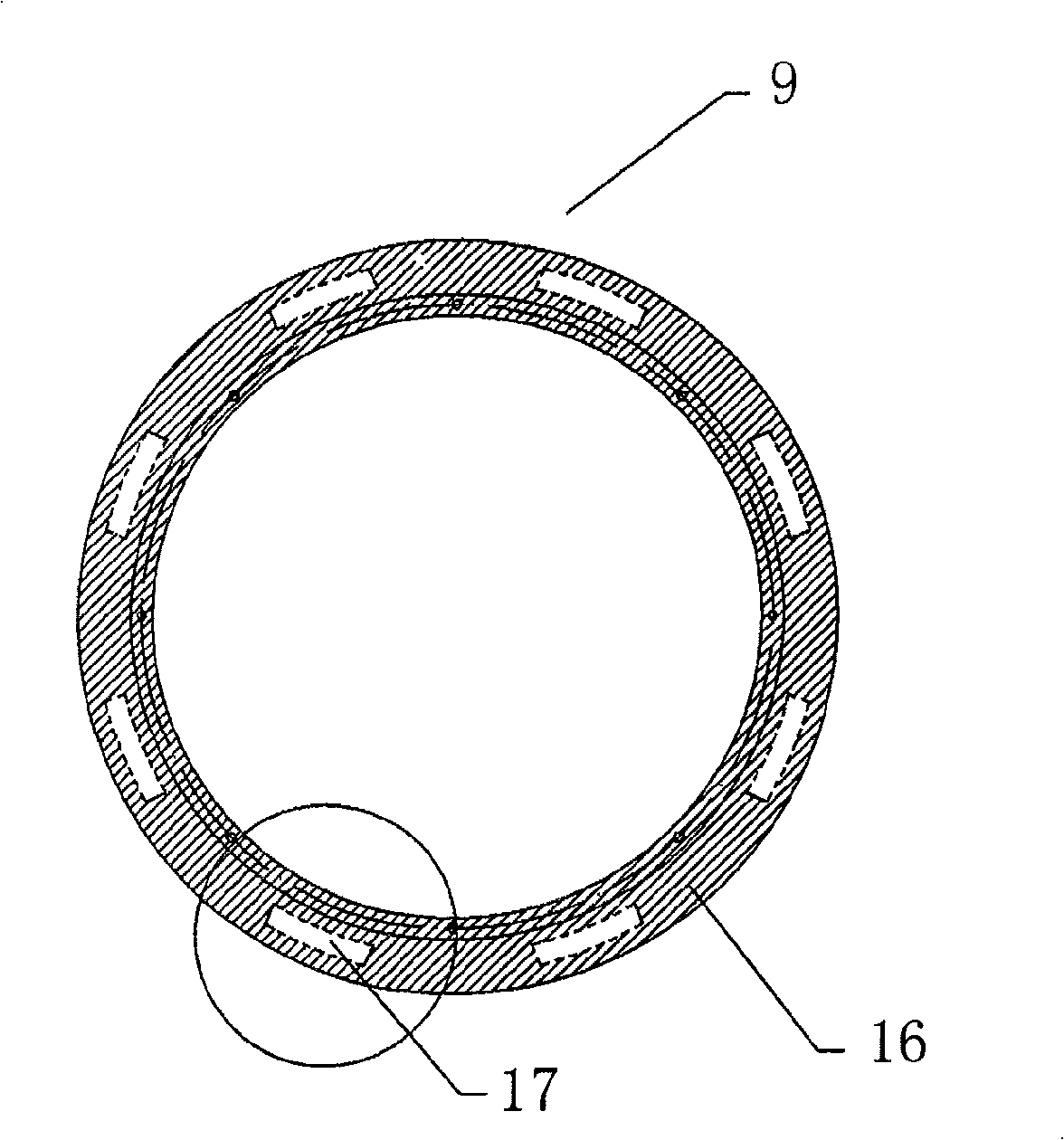

[0019] Such as figure 1 , figure 2 As shown, the structure of the present invention includes a high-pressure chamber 1 with a high-pressure nozzle 2 and a cavity formed inside, a frame for retaining, a high-pressure conduit shaft 3 with a water flow channel inside, and the high-pressure chamber 1 is composed of a front cover 4 and a rear cover 5 Composition, the two are riveted by screws fixed on its outer edge, and a cavity is formed inside the high-pressure chamber 1, on the front cover 4, and corresponding to the position of the internal cavity, there are multiple holes communicating with the cavity and oblique The high-pressure nozzle 2 arranged in the direction, the high-pressure nozzle 2 is evenly distributed on the front cover according to the circumference and forms a certain angle outward with the central axis of the high-pressure chamber 1, the optimal angle is 45°, the high-pressure nozzle 2 arranged obliquely makes the spray The reaction force generated by the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com