Gas protected tungsten pole argon arc welding automatic controlled system adapter

An automatic control system, argon tungsten arc welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of inability to detect the welding process status in real time, unable to communicate with the welding process control, and not having automatic detection of the welding process status Function and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

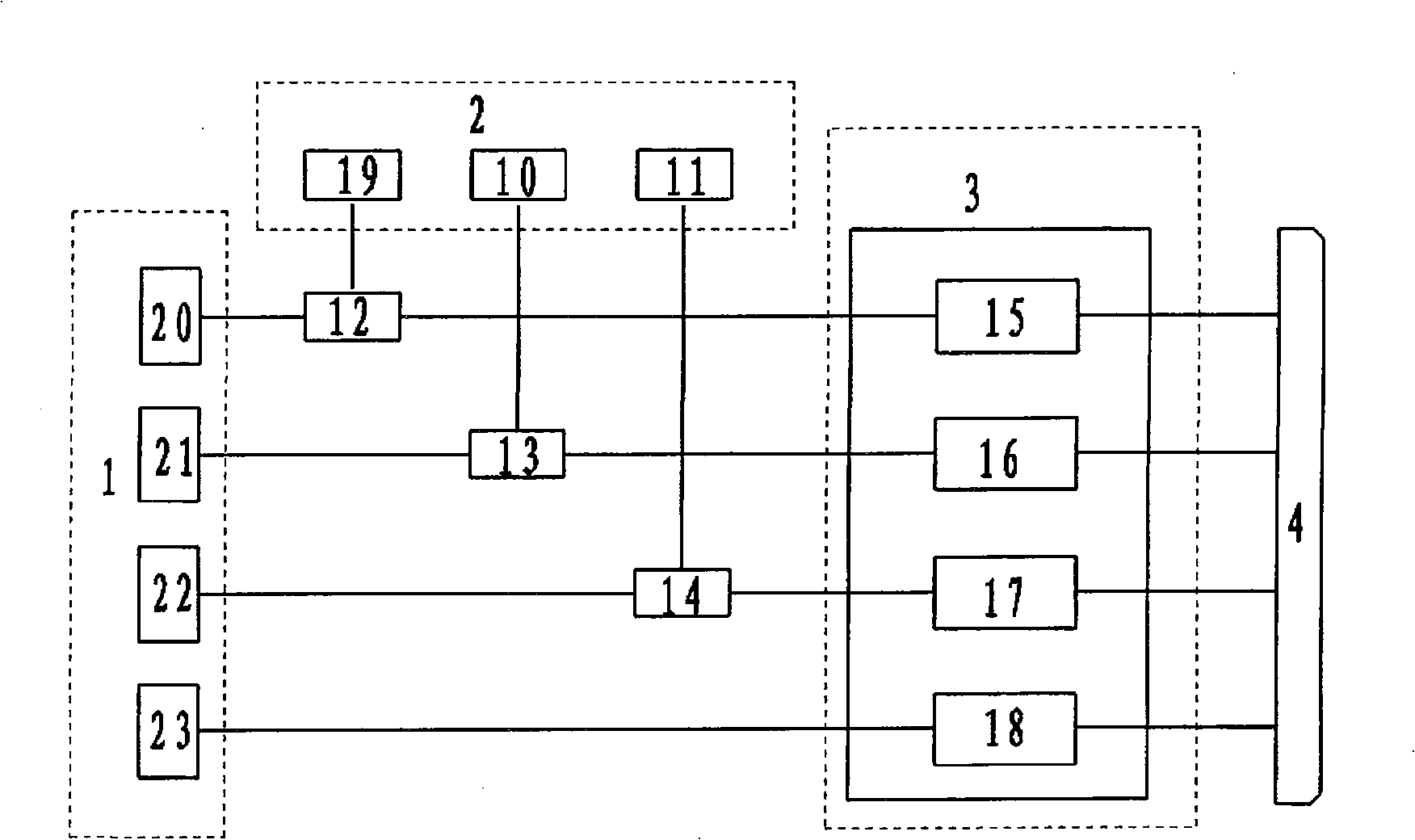

[0036] Such as figure 1 As shown, this embodiment includes: a welding power supply interface circuit 1, a manual control circuit 2, an automatic control circuit 3, a computer interface circuit 4, a first switch 12, a second switch 13, and a third switch 14, wherein:

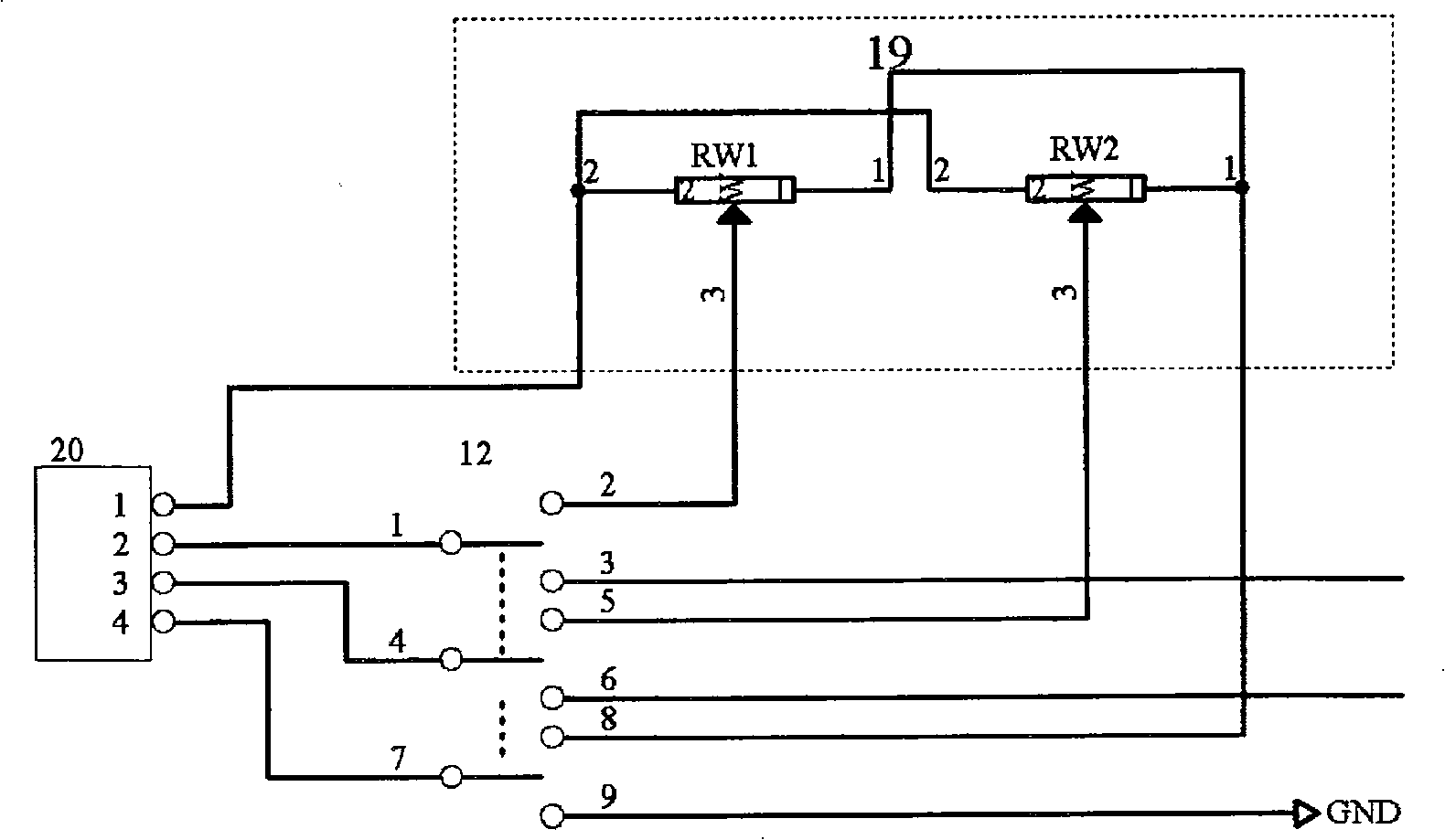

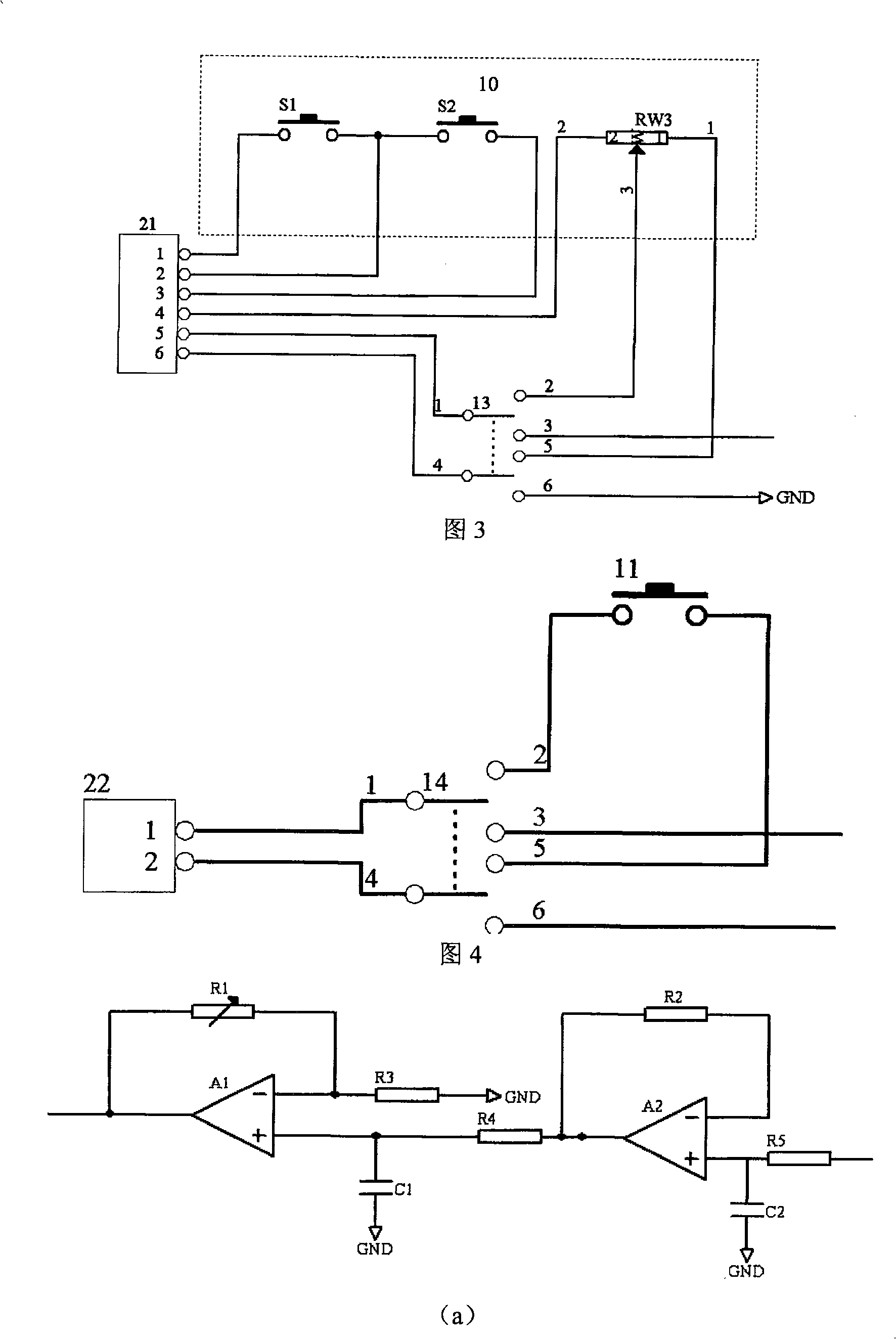

[0037] The manual control circuit 2 includes: a manual welding current control circuit 19, a manual wire feeding control circuit 10, an arc start switch 11, the manual welding current control circuit 19 is connected to a selection terminal of the first switch 12, and the manual wire feeding control circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com