EVA leftover disintegrating machine

A pulverizer and edge technology, applied in the direction of mechanical material recovery, recycling technology, grain processing, etc., can solve problems such as affecting product quality, increasing the burden on enterprises, destroying material understanding, etc., to improve recycling value and recycling rate. The effect of improving and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

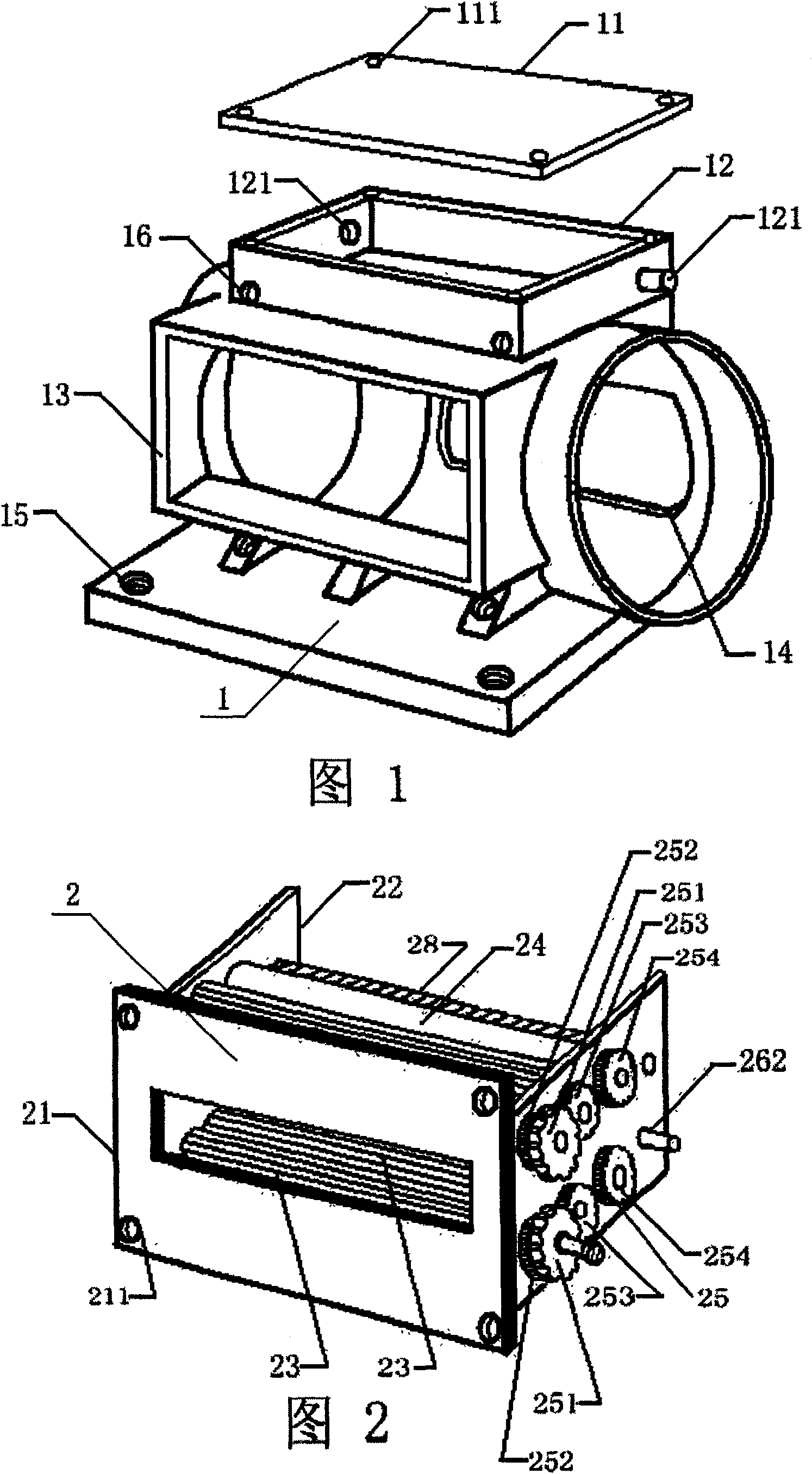

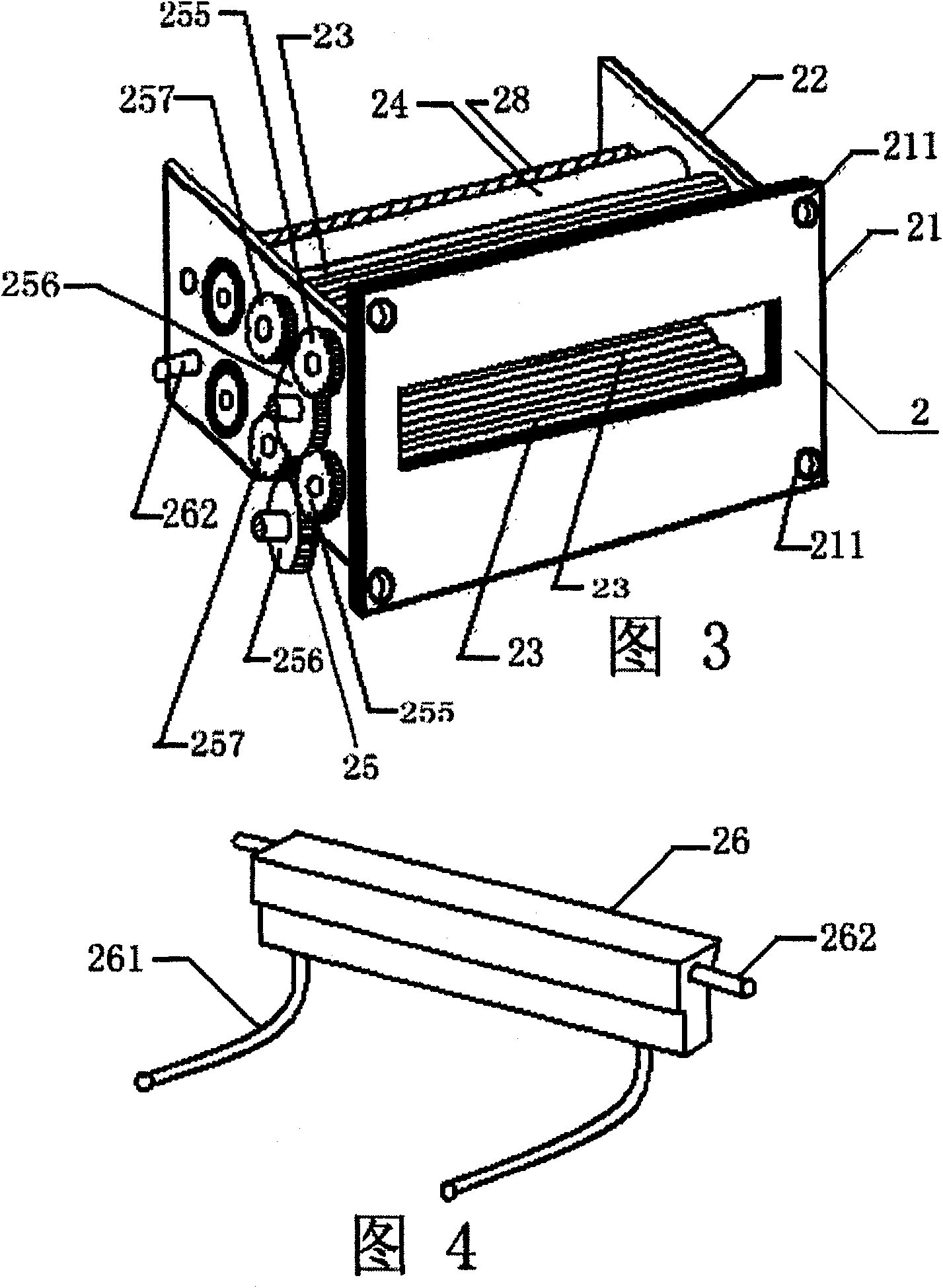

[0039] An EVA corner grinder is composed of a casing 1, a feeder 2 and a grinding wheel 3.

[0040] Such as figure 1 As shown, there is an opening at the front and rear of the casing 1, and there is a small rectangular air inlet under the rectangular opening 13 in front. Fixed connection, the opening 14 at the back is the discharge port, the bottom of the casing 1 has four positioning holes 15 that can be used to fix the casing, and the top of the casing 1 has a water tank 12, the purpose is to cool the casing , there are two small round holes 121 on the wall of the tank, which are the water inlet hole and the water outlet hole respectively, which are connected with the two ends of a water pipe respectively, so that water resources can be recycled, and there is a square water cover 11 above the tank 12, the purpose of which is to prevent The water in the water tank 12 splashes out and prevents the dust from entering the water tank 12. The four corners of the water cover 11 ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com