Device for preventing suspension area from breaking while taper piece filling liquid and drawing deep forming and forming method

A liquid-filled deep drawing, suspended area technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as deformation, large impact of the plate, and achieve the effect of reducing cost, small rebound, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

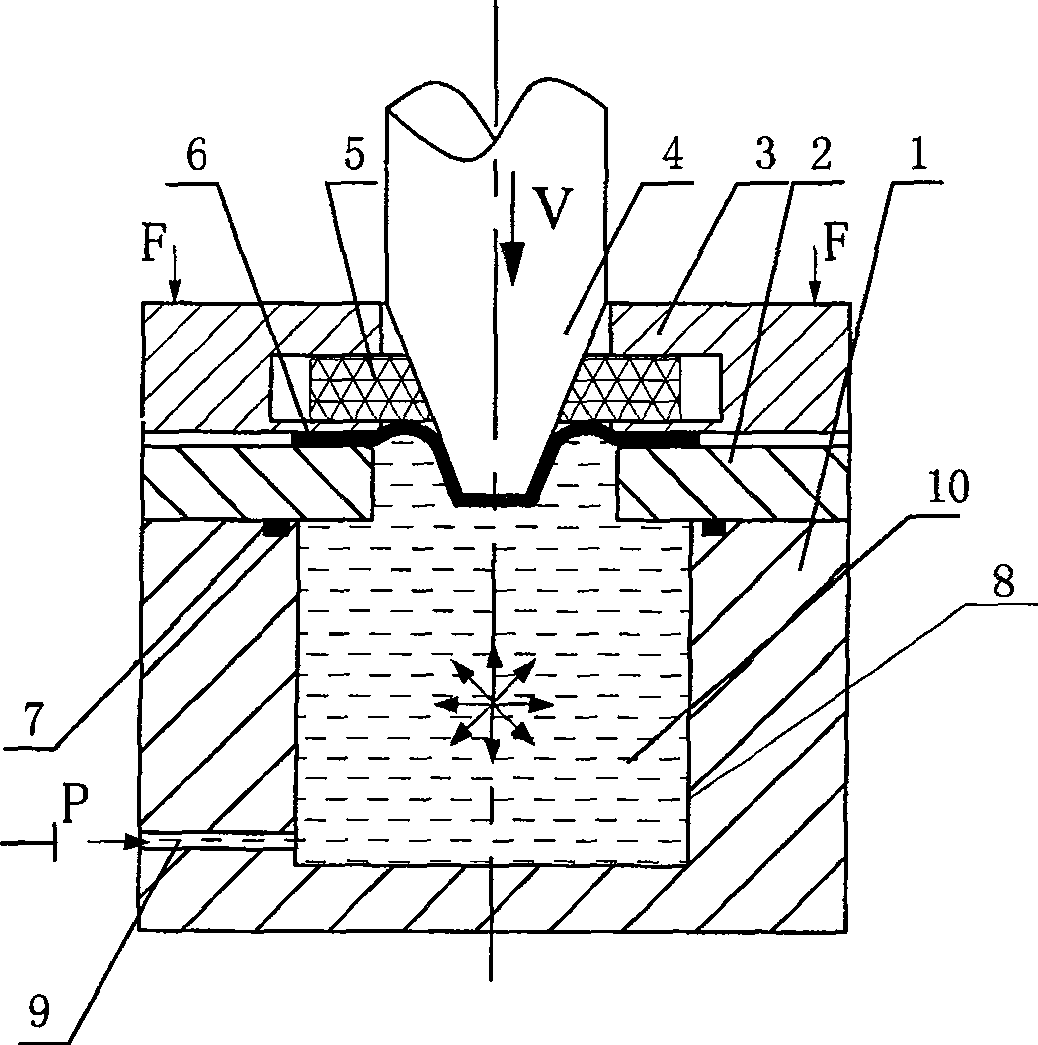

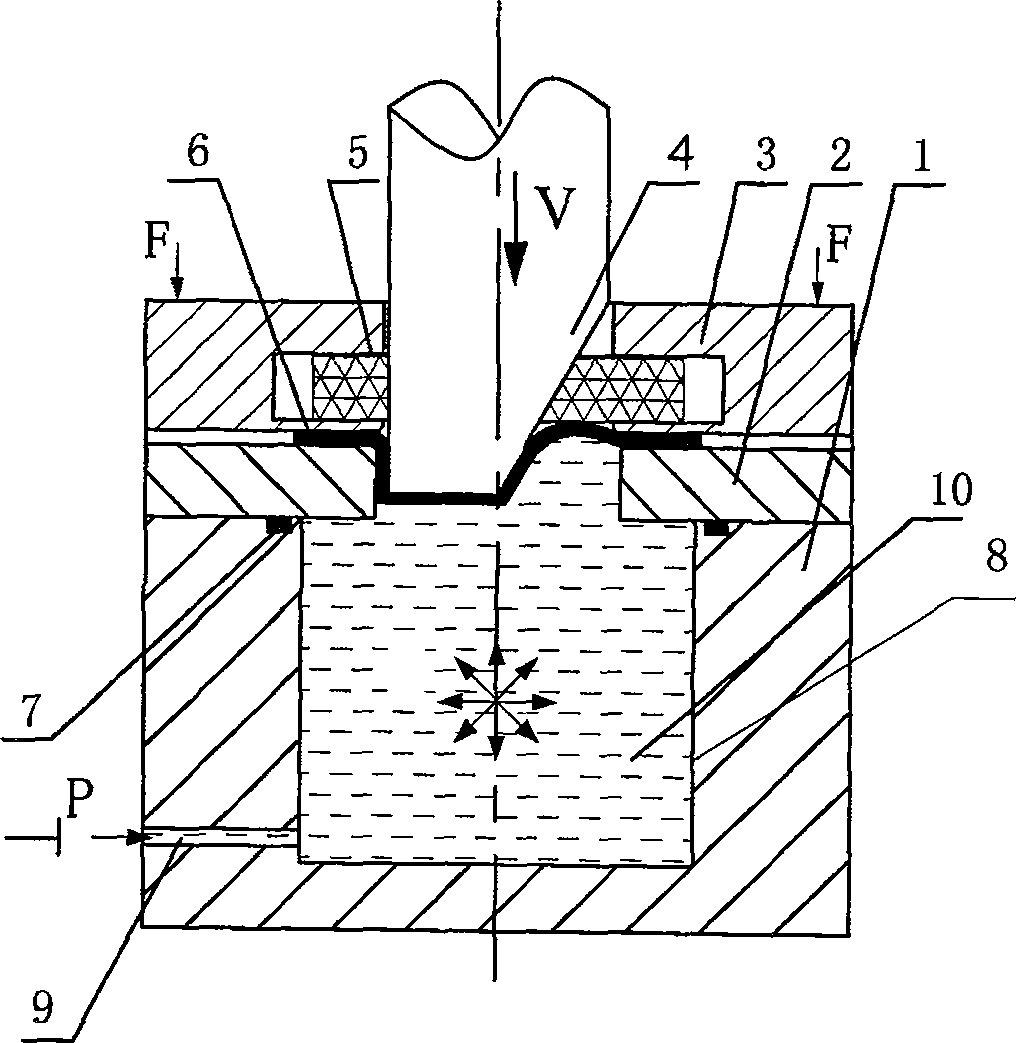

[0014] Specific implementation mode one: combine figure 1 The present embodiment will be described. This embodiment is composed of a fluid medium cavity 1, a die 2, a rigid blank holder 3, a punch 4 and a flexible support ring 5. The die 2 is arranged above the fluid medium cavity 1, and the lower plane of the die 2 is in contact with the The upper plane of the fluid medium cavity 1 is fixedly connected, the rigid blank holder 3 is arranged above the die 2, the inner ring of the rigid blank holder 3 has a groove, the flexible support ring 5 is arranged in the groove, and the flexible support ring 5 Urethane rubber material is used, and the plate blank 6 is placed between the rigid blank holder 3 and the die 2. There is a medium cavity 8 at the center of the upper surface of the fluid medium cavity 1, and the lower left side of the fluid medium cavity 1 is provided with A liquid injection hole 9 communicated with the medium chamber 8, and the liquid injection hole 9 communicat...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 The present embodiment will be described. Both the die 2 and the flexible support ring 5 in this embodiment are provided with inner holes for the punch 4 to pass through, and the maximum outer diameter of the punch 4 is smaller than the inner diameters of the rigid binder ring 3 and the die 2 . Ensure that the up and down movement of the punch 4 is deep drawn.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 The present embodiment will be described. The size difference between the inner diameter of the concave die 2 and the maximum outer diameter of the male die 4 in this embodiment is greater than the thickness of the formed plate blank 6 . When the plate blank 6 is pressed into the die 2, it will not break.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com