Steel for high-strength weather-proof low-alloy electric force bar and preparing method thereof

A low-alloy steel and high-strength technology, applied in temperature control, etc., can solve the problems of poor welding performance, high cold crack index, and high carbon equivalent of steel, and achieve the effects of easy and stable control, low cost, and low carbon equivalent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

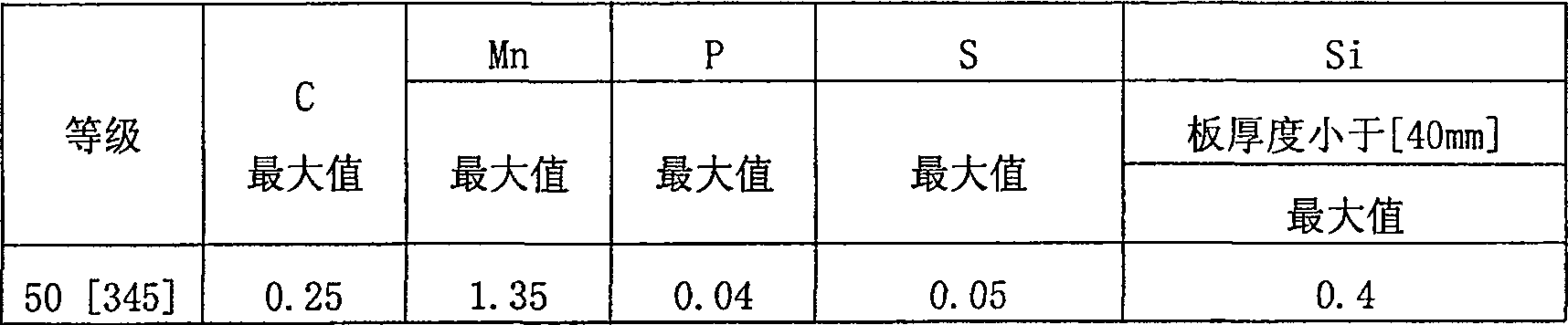

[0034] 1. The chemical composition weight percentage of weathering steel is as follows:

[0035] C: 0.07%, Si: 0.25%, Mn: 1.25%, S: 0.012%, P: 0.015%, Cu: 0.23%, Al: 0.024%, Nb: 0.021%, and the rest are Fe and trace impurities.

[0036] 2. The manufacturing method of weathering steel, the production process includes molten iron pretreatment, compound blowing converter smelting, LF ladle refining, soft argon blowing, slab continuous casting, and 1500 wide band rolling. The operation steps are as follows:

[0037]The molten iron is desulfurized by spraying magnesium particles in the molten iron tank. The sulfur in the molten iron is controlled below 0.020%, and the temperature is not lower than 1250 ° C. After the desulfurization is completed, the slag on the surface of the molten iron is removed. The pretreated molten iron enters the converter for smelting, and the slag-forming material is added 3 minutes before the end point. Endpoint control: C: 0.07%, S: 0.020%. Before ta...

Embodiment 2

[0041] 1. The chemical composition weight percentage of weathering steel is as follows:

[0042] C: 0.08%, Si: 0.22%, Mn: 1.21%, S: 0.010%, P: 0.012%, Cu: 0.25%, Al: 0.034%, Nb: 0.025%, and the rest are Fe and trace impurities.

[0043] 2. The manufacturing method of weathering steel, the production process includes molten iron pretreatment, compound blowing converter smelting, LF ladle refining, soft argon blowing, slab continuous casting, and 1500 wide band rolling. The operation steps are as follows:

[0044] The molten iron is desulfurized by spraying magnesium particles in the molten iron tank. The sulfur in the molten iron is controlled below 0.02%, and the temperature is not lower than 1250 °C. After the desulfurization is completed, the slag on the surface of the molten iron is removed. The pretreated molten iron enters the converter for smelting, and the slag-forming material is added 3 minutes before the end point. End-point control and other steps and processes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com