A pressure-constant water supply cluster teaching system

A teaching system and constant-pressure water supply technology, applied in the field of teaching systems, can solve problems such as low teaching efficiency, difficulty for students to understand and master functions, distribution locations, high maintenance costs, etc., to achieve convenient on-site and remote monitoring, man-machine interface Friendly, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

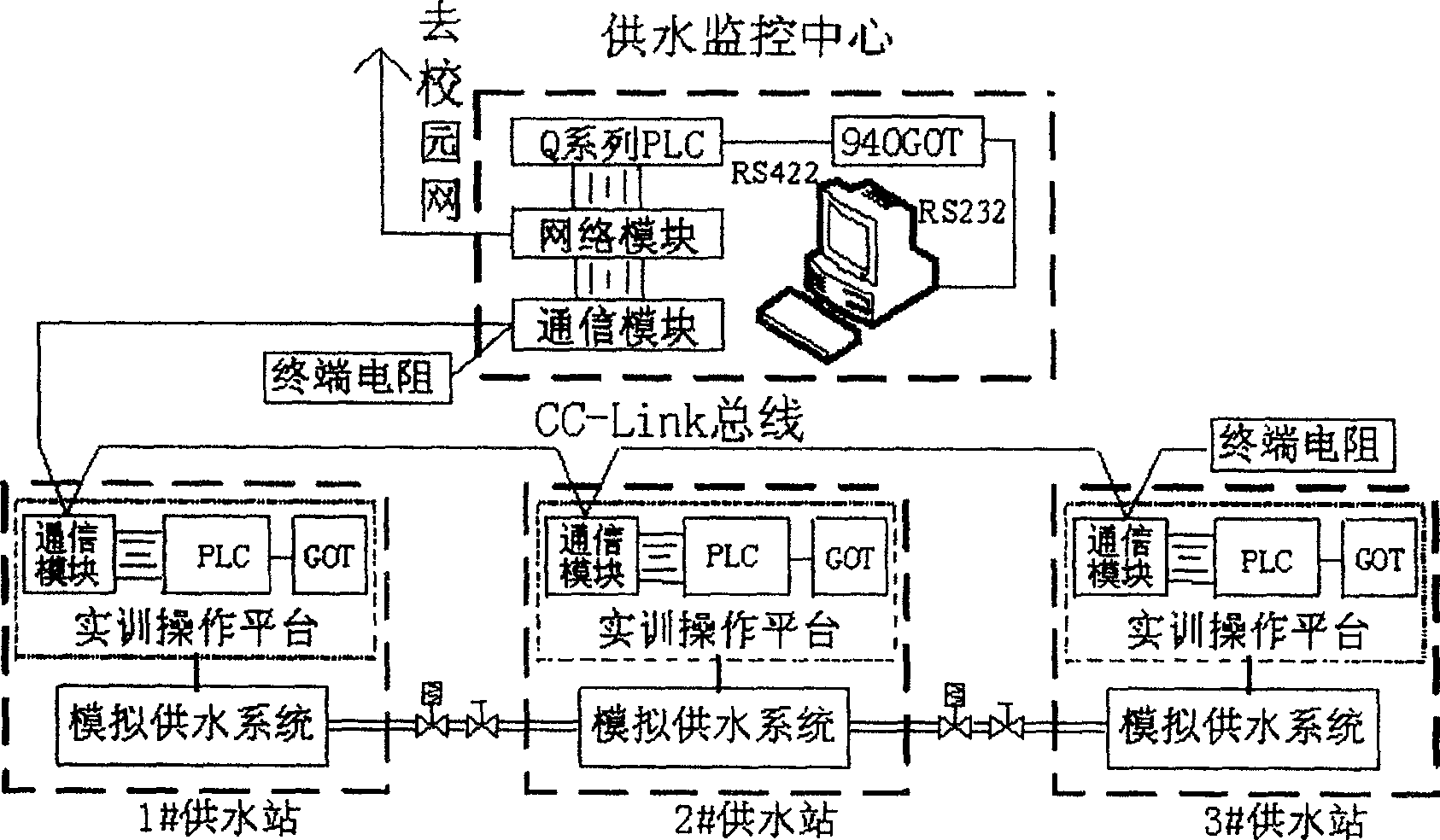

[0027] see figure 1 , is a schematic structural diagram of the constant pressure water supply group teaching system of the present invention. The constant pressure water supply group teaching system of the present invention includes a water supply monitoring center, 1# water supply station, 2# water supply station, and 3# water supply station. In the constant pressure water supply group teaching system, the water supply station can be expanded to 64 stations. Each water supply station can work independently to realize the constant pressure of the small system, and can also form a control group through CC-Link or RS485 to realize the constant pressure of the regional water supply network and ensure the reliability and quality of water supply.

[0028] The water supply monitoring center includes communication module, network module, programmable logic device PLC, computer and touch screen 940GOT. The computer is connected with 940GOT through RS232, and 940GOT is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com